New automation solutions, optimized clamping devices, and smart product variants ensure greater productivity with less effort.

The demands on manufacturing companies are rising: increasing variant diversity, decreasing batch sizes, and growing time and cost pressure. Hainbuch is responding to this development with a consistently expanded product portfolio and will present innovative solutions at EMO 2025 in Hanover (Hall 3, Booth I14) that help make production more flexible and economical or completely automate processes.

Next Step Towards Full Automation: Hainbuch Underlines Its Pioneering Role in Automated Clamping Device Change-Over

Four years ago, Hainbuch was among the first to introduce a market-ready solution that enables automatic change-over of clamping heads—with and without end-stops—as well as complete clamping devices. This technology has been successfully implemented in numerous customer projects, paving the way for cost-effective automation even in small batch production.

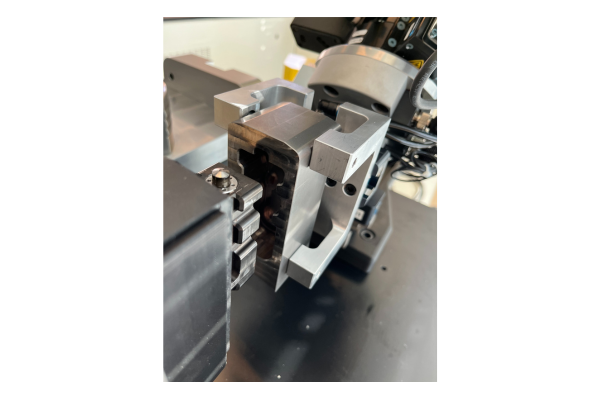

Now comes the next logical step: Hainbuch is introducing a solution for automated jaw change-over in jaw chucks. Even for large O.D. clamping, the clamping elements can now be fully automated for different workpiece diameters—the integrated sensor system ensures this is done reliably.

The result: even in small series or single-part production with frequent workpiece changes, the entire setup process can now be handled completely unmanned—reliably, reproducibly, and economically.

Quality Assurance in Automated Production Processes

To ensure quality in automated processes, IQ clamping devices with integrated measuring intelligence can be incorporated either directly into the process or as a downstream measuring station (“post-process”). The TOPlus IQ chuck for O.D. clamping and the MAXXOS IQ mandrel for I.D. clamping continuously monitor workpiece diameter, workpiece position, and clamping force. The measurement data is transmitted directly to the machine controller and analyzed via non-contact data and energy transmission. The control system then performs a setpoint adjustment. In case of deviations, a message is triggered or a correction is initiated immediately. This reduces scrap and ensures consistent quality. The IQ clamping devices can also detect increasing process forces, thereby identifying tool wear.

well as 5-axis machining centers.

Taking the Tried and Tested a Step Further: New Clamping Devices for Maximum Flexibility

With the new Torok, Hainbuch is optimizing a versatile all-rounder that has proven itself on turning and milling machines, as well as 5-axis machining centers. Its rotationally symmetrical design, reduced interference contour, and interchangeable flange make it especially flexible in application. The Torok allows for sensitive manual clamping, provides reliable workpiece stabilization through axial tension against the end-stop, and can be quickly adapted for I.D. or jaw clamping using Hainbuch System adaptations—a true asset in modern production environments.

Also new to the range are clamping heads with insert jaws starting from size 125. Handling larger clamping heads was previously nearly impossible without a crane due to their heavy weight. The new, more cost-effective version, featuring a base body with replaceable insert jaws, significantly reduces this effort: the clamping head is much lighter, making it easier and quicker to handle. In terms of stability and repeatability, this new solution matches the classic design. Moving forward, customers can choose between the proven one-piece version and the new variant with interchangeable insert jaws—depending on the application and individual requirements.

Live at EMO 2025 in Hanover

Whether automation, set-up time optimization or ergonomic working – Hainbuch shows how modern workholding technology can make a decisive contribution to increasing productivity today. Visit Hainbuch from September 22 to 27, 2025 in Hall 3, Booth I14 – and experience live how intelligent workholding technology is shaping the production of the future.

COMMENTS