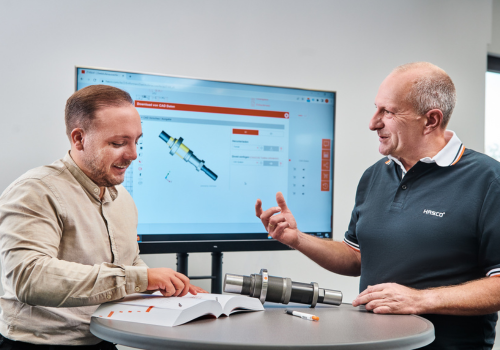

HASCO has introduced new CAD product configurators that enable engineers to generate precise, application-specific CAD data quickly and seamlessly. These tools allow individual configuration and direct integration into the design process, making even complex requirements easy to implement with accuracy and efficiency.

Among the highlights is the two-stage ejector Z169/…, whose CAD data can be customized with parameters such as stroke and plate thickness, ensuring immediate availability of accurate design data. Complementing this, the flange Z167/… offers a flexible and efficient connection to the clamping plate.

With these innovations, HASCO enhances design flexibility and supports engineers in achieving faster, more reliable results in moldmaking and related applications.

HASCO continues to strengthen digital engineering support with its enhanced CAD product configurators, delivering precise, application-oriented data that integrates directly into the design process. The configurators enable tailored adjustments, automatic handling of complex calculations, and consistently reliable data models — significantly reducing effort while boosting process reliability.

A standout innovation is the CAD data for HASCO O-rings, which uniquely includes an integrated groove. This eliminates the need to manually search for installation dimensions. Designers also benefit from construction data that accounts for different sealing types — axial or radial — streamlining the design process and saving valuable time.

The stroke counter A5710/… further highlights HASCO’s digital advantage, offering flexible frame configurations with adjustable screw positions and installation space sizes. Components selected through the HASCO webshop are automatically integrated, minimizing rework and ensuring consistent designs.

Together with solutions such as the two-stage ejector Z169/… and flange Z167/…, these digital tools empower engineers with greater precision, flexibility, and speed — simplifying moldmaking and advancing efficiency across applications.

COMMENTS