-Dr BURR by Stitch Overseas Private Limited

In precision manufacturing, the seemingly small details often determine product quality, safety, and performance. Chamfering and deburring—two critical yet sometimes overlooked finishing processes—play an essential role in refining machined parts. From removing sharp edges and burrs to facilitating assembly and improving aesthetics, these processes span industries from automotive to electronics. This article explores how chamfering and deburring contribute to manufacturing excellence, the challenges of traditional manual methods, and the advantages of embracing automated solutions for consistent quality and operational efficiency.

Deburring and Chamfering are two essential processes in machining. These operations, often considered as finishing touches, play a crucial role in ensuring the quality, safety, and longevity of products ranging from micro-components in electronics to massive structural steel elements. While Chamfering and Deburring are sometimes performed together, each addresses distinct requirements and challenges.

What is Chamfering ?

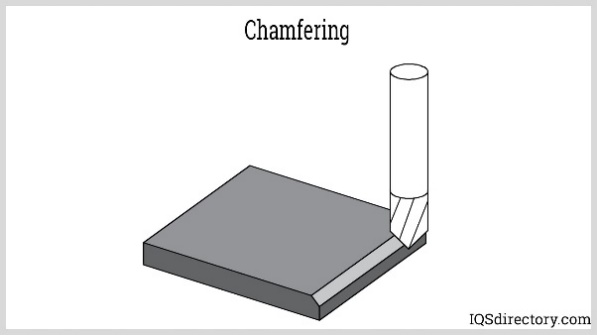

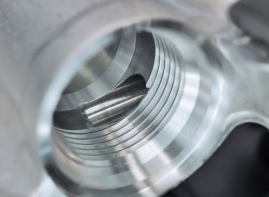

Chamfering is a process where a bevelled edge is created on the edges of a workpiece. It removes sharp corners, facilitate assembly, and enhance both aesthetics and functionality. Chamfering angles may vary depending upon the assembly requirements, but generally the angle tends to be at a 45-degree angle.

Purposes of Chamfering

- Safety Enhancement: By removing sharp edges, Chamfering reduces the risk of injury to workers handling the parts or end-users interacting with the final product.

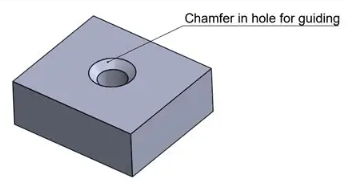

- Assembly Facilitation: Chamfered edges make it easier to fit components together, particularly when inserting parts into holes or slots. For example, Chamfering the edge of a pin or a bolt allows it to be guided more easily during assembly.

- Aesthetic Improvement: Chamfers provide a finished, professional look to machined parts, making them visually appealing and reflecting high manufacturing standards.

- Stress Reduction: Removing sharp corners helps to distribute stress more evenly, reducing the likelihood of material fatigue and cracking under load.

- Preparation for Coating or Welding: Chamfered edges allow for better adhesion of paints and coatings, or improved weld penetration and strength in metalworking applications.

Common Methods and Tools for Chamfering

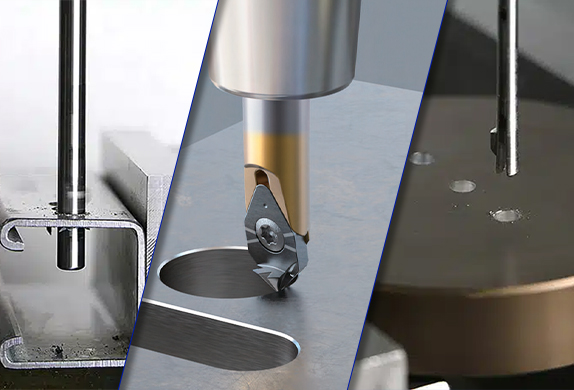

Chamfering can be performed manually or using automated machinery, depending on the production volume, material, and precision required.

- Manual Chamfering: Utilizes files, grinders, or hand-held Chamfering tools. Relies heavily on operator skill and is time-consuming. Aesthetics as well as accuracy and consistency are the major drawbacks of manual Chamfering.

- Machine Chamfering: Employs milling machines, lathes, or dedicated Chamfering machines fitted with Chamfering cutters or end mills. This method ensures consistency, speed, and precision, especially in mass production.

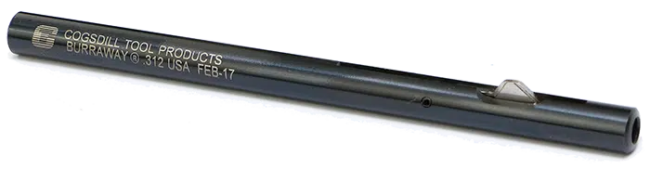

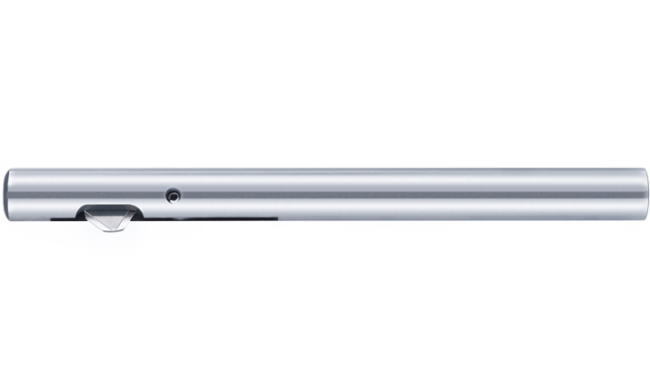

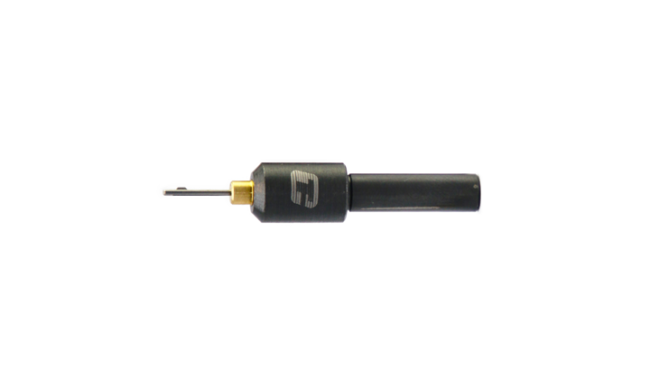

- Specialized Tools: There are numerous specialized Chamfering tools for specific applications, such as countersinks for holes, deburring blades with angled edges, and rotary burrs.

Applications of Chamfering

Chamfering finds use in a vast array of industries, such as:

- Automotive: Gears, shafts, and fasteners are Chamfered to ensure smooth assembly and operation.

- Aerospace: Chamfered edges reduce stress points and potential for cracks in components subject to high loads.

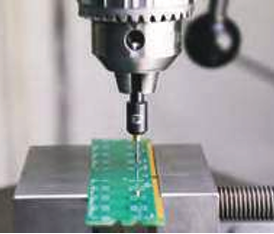

- Electronics: Circuit boards and enclosures are Chamfered to prevent damage to components and ease insertion.

- Construction: Structural steel elements, pipes, and tiles are often Chamfered for safety and fit.

What is Deburring ?

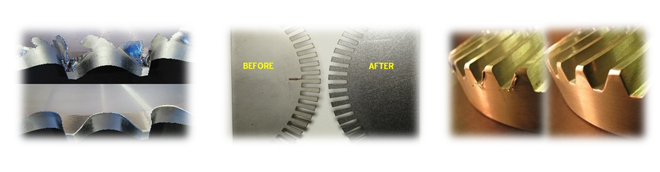

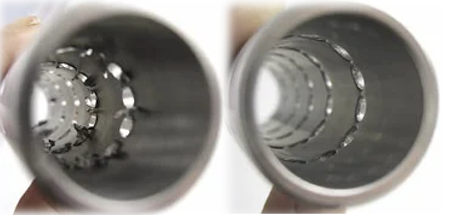

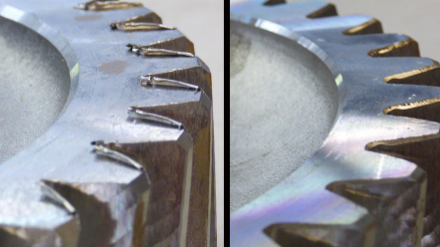

Deburring, closely related to Chamfering, is an essential finishing process in manufacturing. While Chamfering intentionally adds angled edges for function or aesthetics, Deburring specifically targets the removal of sharp, unwanted fragments or protrusions which remain after processes such as cutting, milling, drilling, or stamping.

The goal of Deburring is to ensure parts are smooth to the touch, free from hazardous edges, and suitable for further assembly or use. Effective Deburring not only improves the safety and appearance of a component but can also enhance its performance by reducing friction and preventing premature wear or failure.

Just like Chamfering, Deburring can be accomplished through various methods, including manual techniques. Here again the manual Deburring can create problems similar to Chamfering.

Why Deburring is Critical?

Burr is a major issue in all the manufacturing whether it is Automotive, Aerospace, Medical, Electronics, Defence etc.

Automotive

- Safety: Prevents brake, steering, and engine part failures caused by burr interference.

- Precision Fit: Ensures proper sealing, alignment, and torque during assembly.

- Performance: Reduces friction, wear, and vibration in moving components.

- Cost Savings: Minimizes rework, breakdowns, and warranty claims.

Aerospace

- Flight Safety: Eliminates burrs that could cause hydraulic, fuel, or engine system failures.

- Tight Tolerances: Maintains exact dimensions for high-precision parts.

- FOD Prevention: Stops loose burrs from damaging engines or avionics.

- Reliability: Ensures flawless performance in extreme conditions.

Medical

- Patient Safety: Prevents tissue damage from sharp edges on surgical tools and implants.

- Hygiene: Removes crevices where bacteria can hide, aiding sterilization.

- Regulatory Compliance: Meets strict FDA/ISO requirements for smooth finishes.

- Functionality: Ensures accuracy and smooth operation of medical devices.

Defence

- Operational Safety: Prevents misfires, jams, and malfunction in weapons and systems.

- Durability: Enhances component lifespan under extreme vibration, shock & temperature.

- Interchangeability: Enables quick, burr-free assembly and field repairs.

- Mission Reliability: Ensures no failure during critical operations

Electronics

- Circuit Protection: Prevents short circuits caused by metallic burrs or debris.

- Assembly Precision: Allows perfect alignment of connectors and PCB components.

- Heat Management: Smooth edges prevent hotspots and damage to insulation.

- Miniaturization Reliability: Essential for tiny, delicate electronic parts with very low tolerances.

Across All Industries

Applications areas where Deburring is done are similar to Chamfering. One important point to note is that, Deburring normally does not give accurate angles, since the function of Deburring is only to remove the burrs. If a critical angle is required, Deburring will not serve the purpose, it calls for dedicated Chamfering tools. Chamfering also will leave burrs. Here dedicated Deburring tools will have to be used.

Cycle time or Process time?

In many machine shops, Chamfering and Deburring are still carried out manually. On the surface, it seems like a sensible choice: no need for extra tools, no additional machine programs, and supposedly faster cycle times. But is this really the most profitable approach?

The truth is: cycle time is only one piece of the puzzle.

Profitability isn’t decided by how quickly a component leaves the CNC spindle. It’s defined by the total process cost — from raw material in, to a finished, defect-free part delivered to the customer. Every second and every rejection matters.

The Hidden Costs of Manual Deburring & Chamfering

Let’s imagine a typical scenario:

- Parts come off the machine, dimensionally perfect.

- They’re stacked near the operator’s table for manual finishing.

- The clock starts ticking. How long will it take? Nobody knows. It depends on the operator’s skill, speed, and even mood.

This creates several risks:

- Unpredictable process time → You can’t plan or measure accurately.

- Pressure-induced errors → Rushed work leads to inconsistency.

- Aesthetic rejections → File marks, scratches, dents can scrap an otherwise perfect part.

What looked like a “saved cycle time” suddenly turns into uncertain cost, wasted time, and rejected output.

The Smarter Approach: Automating Deburring & Chamfering

To truly optimize profitability, manufacturing operations should consider focusing not just on machine cycle time but on the total end-to-end process cost. Automation of deburring and chamfering processes helps reduce dependence on manual labor, which can be variable and inconsistent. Automated solutions provide consistent and repeatable quality, even in hard-to-reach areas, while reducing the risks linked to operator-dependent processes. By adopting automation, manufacturers can improve efficiency, lower the incidence of defects and rejections, and gain better control over their overall production costs.

This version removes specific brand mentions and sales language while keeping the core message about benefits of automation in process control and profitability. Let me know if any further adjustments are needed.

Conclusion

Effective chamfering and deburring are not mere finishing touches but foundational steps ensuring product integrity, safety, and longevity. As manufacturing moves toward greater precision and automation, reliance on manual methods is increasingly untenable due to variability and hidden costs. Automated deburring and chamfering solutions offer manufacturers control, reliability, and significant economic benefits by minimizing rework and rejects. Adopting advanced tools can transform these processes from cost centers into key contributors to manufacturing excellence and profitability.

COMMENTS