Hexagon’s Manufacturing Intelligence division has announced a major step forward for the mould & die and precision machining sectors with the launch of the first production-ready integration between its WORKNC CAM software and a cloud-based Tool Library. The new integration enhances the way CAM programmers access and apply validated tooling data and established machining strategies, helping to accelerate programming workflows while delivering greater consistency and predictability when machining complex components.

Increasing part complexity, tighter tolerances and the scarcity of experienced programmers continue to place pressure on machinists. Many lose valuable time recreating tooling assemblies, maintaining fragmented data or relying on undocumented knowledge exchange across shifts. Hexagon’s latest release addresses these challenges by unifying enhanced workflow automation in WORKNC with centralised, validated cutting-tool information from industry leading tool manufacturers (OEMs) through the platform.

“Reliable tooling information is one of the most powerful levers for reducing programming time and eliminating variability,” said Steffen Dilger, president of Hexagon’s Production Software Division. “As manufacturers adopt more advanced automation and AI-assisted programming, centralised and high-quality tool data will play an increasingly critical role. Our focus is on removing workflow bottlenecks and connecting the full manufacturing toolkit, from tool selection through simulation and NC verification.”

Cloud-powered tooling for faster, smarter CAM programming

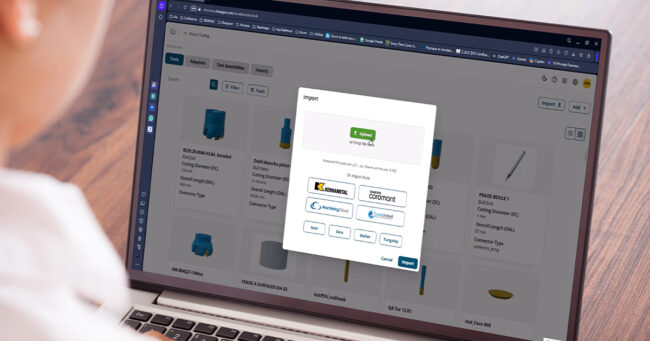

The Tool Library provides WORKNC users with direct access to verified cutting-tool data from a growing network of leading tooling partners. Programmers can pull tooling information directly into their CAM environment without re-entry or model reconstruction, reducing set-up time and ensuring digital tool definitions match actual cutting performance.

“This integration helps manufacturers adopt smarter, more efficient digital workflows,” said Dr. Carlonda Reilly, Chief Technology Officer, Kennametal. “By combining our validated tooling data with Hexagon’s powerful CAM technology, we’re advancing our strategy by expanding our digital capabilities to better serve machining shops worldwide.”

“Having Sandvik Coromant tooling available inside the Tool Library means less guesswork and more productive machining,” said Tobias Unosson, Business & Partner Development Manager, Sandvik Coromant. “With validated data at your fingertips, shops can standardise, reduce setup time, and maintain consistent best practices. Smarter tools mean smarter workflows.”

This growing number of featured partners also includes MachiningCloud and ToolsUnited, with additional partners being onboarded as the ecosystem expands, giving shops broader access to validated tooling data.

The integration of the Tool Library enables accurate digital twins of tools and assemblies, automatic application of material-specific cutting data, and the sharing of standardised tooling definitions across teams. Its cloud-based architecture supports scalability and consistency across thousands of tool items, while searchable catalogues give users direct access to OEM information without installing additional applications or consuming CAM licenses.

Enhanced automation and quality improvements in WORKNC 2025.4

Alongside the Tool Library integration, Hexagon has introduced new automation and finishing enhancements designed to simplify complex programming tasks and help shops achieve more consistent machining outcomes:

- Improved finishing quality: A new Parallel Finishing algorithm delivers cleaner transitions at surface edges and improves geometry accuracy. Combined with toolpath extension in tangency, it reduces tedious CAD preparation.

- Simplified programming: New enhancements improve detection of remaining material and provide finer control of tool entry and exit positions, helping programmers generate collision-safe toolpaths with less manual intervention.

With this release, Hexagon continues to prioritise practical automation that fits existing processes, enabling manufacturers to modernise at a pace that suits their operations.

The latest WORKNC release and Tool Library integration are available now. Customers can access the update via WORKNC | Hexagon or contact their Hexagon representative for details.

COMMENTS