EMO Hannover 2025 showcasing production technology for the modern factory

From ice cream machines to wheel loaders, engineering products cover a wide and diverse range. Yet, most manufacturers are tackling similar key challenges—modernizing their production lines, addressing the shortage of skilled workers, improving resource efficiency, and adopting circular economy practices.

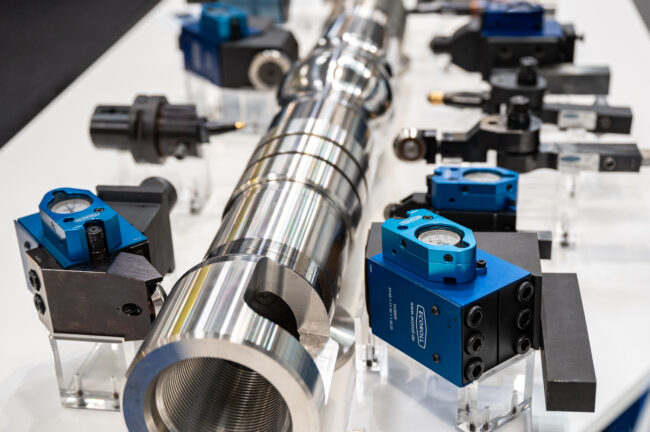

EMO Hannover 2025, the world’s leading trade fair for production technology, will address these issues under the theme ‘Innovate Manufacturing’. The event will showcase cutting-edge solutions and offer engineering companies valuable insights and innovations. It will also help businesses connect with the right partners to support their modernization journey—saving time and reducing investment risks.

Embracing new technologies

Now more than ever, the entire industry—not just small and medium-sized companies—needs to adopt new, scalable technologies that deliver proven results and boost efficiency from day one.

EMO Hannover 2025 provides direct access to top manufacturers and suppliers of tailored production solutions for the engineering sector. The trade fair highlights the latest in metalworking technology, with live demonstrations of machine tools in action. Visitors can also engage with industry experts through discussions at exhibitor booths, as well as in presentations, workshops, and hands-on sessions.

Emphasizing on the trade fair highlights, Dr. Markus Heering, Executive Director of EMO organizer VDW (German Machine Tool Builders’ Association), said, “The EMO is unique among the trade fairs in presenting the entire metalworking value chain – from machine tools, production systems and additive processes through to precision tools, automation, metrology, quality assurance, software and accessories”. The EMO motto ‘Innovate Manufacturing’ is therefore more than just a slogan, says Heering, it is a call to suppliers and users to be bold in exploiting the possibilities opened up by the new technologies, he further adds.

Digitalization is revolutionizing engineering

This applies in particular to the megatrends of automation, digitalization and artificial intelligence. Advancing digitalization is revolutionizing engineering, the VDW believes. A decisive factor here is the networking of all machines in the process chain. The opportunity to experience this live is what makes EMO unique. Machine tools now come pre-equipped with extensive sensor and monitoring systems. Exhibitors need to dispel trade visitors’ concerns about the possible loss of data sovereignty or the threat of cyberattacks. The exhibiting companies believe it is important to facilitate the transition to data-driven production. Systems that run exclusively on or in individual machines and within the customer’s own network will be on display. It is entirely up to users to decide whether they allow the exchange of data – for example, with external parties, such as the machine manufacturer or partners in or outside the value chain, either now or at some point in the future. Genuine added value is created when maintenance cycles can be predicted, downtimes can be minimized, or data for documenting the carbon footprint within the supply chain can be issued at the touch of a button.

Machine learning, a sub-area of artificial intelligence, opens up a new dimension of self-organizing production. This allows companies to respond more flexibly to changes in the market and to individual customer demands. It is a crucial prerequisite for maintaining innovativity and competitiveness in the long term.

Addressing skilled labor shortages

Digitalization and automation of production can be combined with strategies aimed at countering the shortage of skilled workers in engineering. Automated assistance systems, for instance, can support machine operators while simultaneously increasing productivity, quality and efficiency. In addition to technical solutions, EMO is also addressing the question of how the training programs for the next generation of skilled workers can best be adapted to meet the latest requirements regarding technological development, digitaliza-tion and artificial intelligence.

The changes affecting engineering also include sustainability. More and more countries are taking measures to protect the climate and invest in the green transformation of their industry. In production, there is a stronger focus on consuming resources more sparingly, using energy-efficient machines and production processes, and setting up circular economies for products and materials. As the VDW reports, immensely high visitor interest in this topic was already apparent at EMO 2023. The Sustainability Area at EMO 2025 will provide a focal point for modern solutions aimed at bringing about the sustainable production of the future and at answering visitors’ questions. This is a topic which is clearly at the top of the agenda when it comes to the modernization of production.

In the lead-up to the trade fair, EMO exhibitors can use the mechanical engineering landing page to highlight what they have in store for customers from the mechanical and plant engineering sector. Until the fair concludes on 22–26 September 2025, exhibitors will regularly share updates on what visitors from this sector can expect at their stands.

COMMENTS