From compressing development cycles and validating designs with near end‑use materials, to integrating conformal cooling and hybrid machining for tighter tolerances, additive manufacturing is redefining what tool rooms can achieve. Advances in resins, metals, and composites are closing the gap with traditional engineering standards, while AI‑driven automation and digital supply chains are unlocking agility at scale. As global adoption accelerates and new generations of engineers embrace additive design, tooling is poised to evolve from a preparatory step into a strategic force driving faster innovation, smarter production, and more sustainable manufacturing worldwide.

-By Neha Basudkar Ghate

Industrial production is undergoing a profound transformation in the way essential components are designed and manufactured. Tools that form the backbone of casting, machining, assembly, and other manufacturing processes are at the centre of this shift. Traditionally, tool creation has been a labour-intensive and costly endeavour, often constrained by complex geometries and material limitations.

This transformation is being driven by ground-breaking innovations that enable manufacturers to overcome these long-standing barriers. At the forefront of this change is Additive Manufacturing (AM), a technology that has rapidly evolved from its origins in prototyping and design iteration into a core pillar supporting next-generation tooling, die, and mould manufacturing.

Fuelled by advances in academic research and private-sector innovation, AM has achieved dramatic progress in speed, precision, and material capabilities. These developments have catapulted the technology into the heart of global manufacturing competitiveness, opening doors to new industrial possibilities and redefining the standards of efficiency, adaptability, and design freedom.

Rethinking Manufacturing and the Tooling Imperative

Manufacturing itself is defined as converting raw materials into finished products through a series of value-added steps, with tooling representing the ‘fifth horizontal’ underpinning every industrial vertical. Tooling includes essential components like jigs, fixtures, moulds, dies, and stamps that support casting, machining, assembly, and more. Traditionally achieved through machining, casting, or fabrication, toolmaking is often time-consuming, expensive, and limited by design complexity.

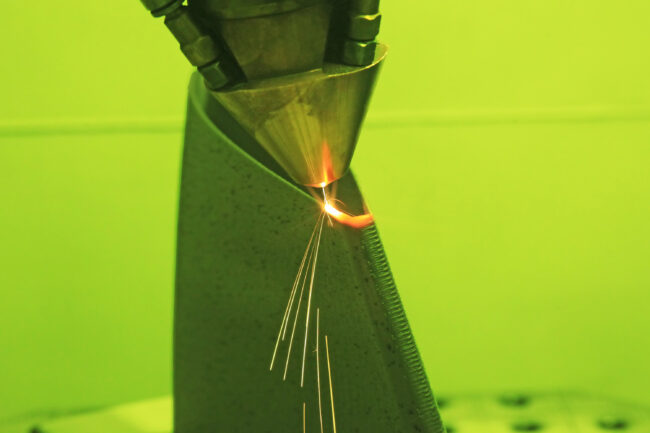

AM, by contrast, builds components layer by layer according to a digital model. This deposition-based workflow breaks free of conventional constraints, enabling geometrically complex, one-piece tools with conformal cooling channels, custom cavities, and internal features that were previously unachievable. Recent advances in automation are now pushing AM beyond its prototyping roots into factory-level production. “Automation is transforming 3D printing from a manual, workshop‑level process into a predictable, always‑on production system,” said Michael Agam, General Manager (APAC), Formlabs. “Integrated hardware ecosystems, intelligent software orchestration, and factory‑level digitisation are converging to enable true ‘lights‑out’ manufacturing”, while “continuous builds, automated post‑processing, and remote error handling improve equipment utilisation and shorten lead times for tooling and modular fixtures”, he explained.

Enabling Industries, Empowering Toolmakers

AM’s ability to instantly iterate tool design, reduce sub-assembly count, and localise supply chains addresses ingrained industry challenges. The diminishing costs and improved performance of AM materials, especially in polymers and select metals, make the technology attractive not just for prototyping but for small-batch and highly customised mid-volume production.

Tooling components such as mould cavity inserts, extrusion dies, and robot end-effectors are often required in low volumes, with complex geometries that drive up the costs and lead times of traditional fabrication. When a tool breaks or requires a design update, AM’s digital workflow allows for rapid design changes, frequent replacement, and quick in-house production, minimising supply chain risks and maximising uptime.

The Spectrum of Additive Processes in Tooling

AM brings the following palette of processes tailored to different tooling needs:

- Fused Deposition Modeling (FDM): Popular for prototyping and low-volume durable plastic parts, FDM builds structures layer by layer from heated thermoplastic filament. While affordable and versatile, FDM often yields lower surface finish and mechanical performance compared to other AM techniques.

- Stereolithography (SLA) & Low Force Stereolithography (LFS): SLA cures liquid photopolymer resin with a UV laser to create ultra-precise parts. LFS further streamlines process consistency, surface smoothness, and fine-feature reproduction. Both are ideal for intricate, high-tolerance tooling, such as gauge blocks and mould inserts. Highlighting the impact of this transition, Agam explained that “the shift from conventional SLA to LFS has significantly advanced precision and repeatability”. By reducing peel stresses, “LFS achieves smoother surfaces, finer features, and easier support removal, enhancing yield and accuracy for tooling components,” he noted, while emphasising that “it also scales more reliably for larger builds, improving consistency across long production runs”.

- Selective Laser Sintering (SLS) & Direct Metal Laser Sintering (DMLS): SLS leverages powder-bed fusion to create robust, highly-functional parts in polymers or metals in the case of DMLS/SLM without requiring support structures, opening new horizons for direct-injection moulds, conformal cooling channels, and complex insert geometries.

Accelerating Product Development Cycles

AM dramatically shortens development timelines by building parts directly from CAD data, eliminating the need for intermediate tooling. This enables faster validation, multiple design iterations, and parallel progress of prototyping and tooling. Industries such as automotive and consumer goods benefit most, where speed and flexibility are critical to competitiveness.

Having worked in new product development for more than two decades, Aditya Kumar, Managing Director, Marcopolo Products Private Limited, has witnessed the shift first-hand. He explained that prototyping technologies have already “compressed development cycles by more than half” and with advancements in AM, “cycle times have reduced even further”. A bumper assembly with about 20 components can now be produced in just five days, compared to the 21 days required by conventional machining, he said. “This capability allows parallel progress of product testing and production tooling, saving several weeks in the overall development cycle,” elaborated Kumar.

This compression of tooling lead times translates into competitive speed, allowing complex jigs, fixtures, and assemblies to be delivered in days rather than months, greatly accelerating product launches.

Application: Tool Design without Limits

AM has opened new horizons in tool design, enabling geometries and internal features that were once impossible with conventional machining. In the tooling sector, AM is being applied across multiple domains, including:

- Tooling for Moulding: Fast, cost-effective injection and thermoforming tools, ideal for short-run and prototype parts.

- Casting: Investment and sand casting patterns, cores, and shells with complex geometries.

- Forming: Punches, dies, and hydroforming tools with custom channelling and reinforcement.

- Inspection & Assembly (Jigs/Fixtures): Gauge pins, assembly blocks, and robotic grippers that improve precision and repeatability.

Improving tool performance is where AM delivers its most striking advantages. By building components layer by layer, engineers can integrate cooling channels, ejector holes, and venting features directly into the tool body. This eliminates the need for assembly and reduces weak points that often compromise tool life.

As Ankit Sahu, CEO, Objectify Technologies Pvt. Ltd., pointed out, AM is “transforming tooling by building layer by layer, creating geometries that conventional cutting methods cannot achieve… the biggest advantage is producing an entire tool as one integrated piece instead of assembling 15 to 20 components”, a shift that “eliminates assembly errors, weak points, and the need for alignment”.

Equally important is the sustainability benefit. “Because the process uses only the required material, waste is reduced by up to 70%,” noted Sahu. “Cooling channels, ejector holes, and air vents can now be built directly into the tool, improving performance from the first trial,” he added.

Conformal cooling is one of the most impactful innovations enabled by AM. Unlike traditional drilled cooling lines, conformal channels follow the contours of the mould cavity, maintaining uniform temperatures across critical areas. This reduces cycle times by up to 30-40%, improves dimensional accuracy, and enhances surface finish. These benefits have been widely reported in automotive and consumer goods moulding.

Equally transformative are complex core and cavity structures. AM’s freeform capabilities allow honeycomb reinforcement, integrated venting, and the combination of supports with core formation. These structural efficiencies result in lighter, stronger, and more durable tools, while reducing material waste.

Process and Material Considerations

Metal AM tooling remains costlier at high volumes compared to conventional methods, but it delivers unmatched value in low-volume, high-complexity, and rapid replacement scenarios. Typical tolerances achievable with laser-based AM range between ±0.1 and 0.2 mm, with metal moulds capable of reaching surface finishes down to Ra 4 µm. Beyond metals, polymers, ceramics, composites, and advanced alloys such as S7 and H13 tool steels, as well as copper, are increasingly accessible, supporting a wide array of tooling needs across industries.

Hybrid manufacturing, where additive-created geometry is post-processed by CNC, combines the flexibility of AM with the precision of subtractive machining. This ‘best of both worlds’ approach enables ultra-tight finishes and dimensional accuracy suitable for aerospace and medical tooling. At the same time, AI-driven automated mould design is streamlining workflows, while cloud-based file storage is unlocking digital, global supply chains that support distributed manufacturing.

Equally important is the sustainability advantage. AM in tooling not only reduces cycle and lead times but also mitigates waste by 50-70% compared to subtractive routes. Single-piece builds eliminate tolerance stack-up and the need for resource-intensive joining or assembly, directly reducing scrap rates and carbon footprint.

Rapid Validation with Near End-Use Materials

Designers face the crucial challenge of validating concepts using materials that closely mimic those used in final applications. This is especially true in tooling and mould making, where mechanical performance and durability under process conditions directly impact part quality. Kumar explained, “Designers always need to validate their concepts using near end-use materials. Conventional tooling often takes 8 to 10 weeks and demands high capital cost, while soft tooling can be completed in as little as seven days for smaller parts. Even with complex geometries, time savings exceed 50%, giving developers additional room to optimise their designs within tight schedules.”

Such accelerated tooling timelines are possible primarily due to AM technologies such as SLA, SLS, MJF, and FDM, each offering distinct trade-offs in resolution, strength, and speed. Laser-based methods like SLA and SLS, with tolerances below 0.2 mm, excel where precision and detailed surface finishes are paramount, while MJF and FDM prioritise rapid functional part production at high throughput. SLA produces ultra-smooth surface finishes using a UV laser to polymerise liquid resin selectively, making it ideal for presentation-quality tooling prototypes. Conversely, SLS and MJF operate with powdered materials such as nylon, offering strength, complex geometry capability, and scalability, with MJF excelling in speed and batch-to-batch repeatability. FDM, while the most cost-effective, is suited for mechanical mock-ups and functional testing where surface finish is less critical.

Kumar added, “Various additive technologies such as SLA, SLS, MJF, and FDM offer different advantages. Laser-based systems like SLA and SLS achieve tolerances below 0.2 mm, while MJF and FDM deliver precise and functional parts at high speed. Although conventional machining still offers superior accuracy in some cases, additive manufacturing stands out for its design freedom, responsiveness, and unmatched speed.”

Balancing Material Performance and Digital Agility

Successful tooling demands resins and materials that strike a balance between mechanical strength, process compatibility, and end‑use functionality. Developments in resin chemistry are steadily pushing additive materials closer to traditional engineering benchmarks without sacrificing the intrinsic agility of 3D printing. “For tooling designers, resin selection must balance mechanical performance, process compatibility, and end-use properties. These developments are bringing additive materials closer to traditional engineering standards while retaining the digital agility of 3D printing,” expressed Agam.

This balance enables tooling applications that require temperature resistance, wear durability, and dimensional stability, which identify the qualities essential for moulds used in injection moulding or die‑casting processes. Recent advances include heat‑resistant SLA resins capable of withstanding elevated process temperatures, and composite‑filled photopolymers that enhance strength and thermal properties. Together, these innovations are expanding the scope of AM tooling, making it viable not only for prototyping but also for demanding production environments.

Hybrid Manufacturing: Integrated Precision and Complexity

Tooling engineers are increasingly harnessing hybrid manufacturing, combining AM for complex internal features with traditional subtractive machining on critical surfaces, to achieve tight tolerances and superior quality. “By combining additive manufacturing for complex internal geometries with traditional machining for precision surfaces, we achieve tight tolerances and superior accuracy. The ability to design internal cooling and venting features that were once impossible fundamentally changes how tooling engineers think. What once took months can now be done in weeks, wherein engineers can design, print, test, and refine a tool within days. This agility makes it ideal for prototype tooling, bridge tooling, and custom production aids, where speed and adaptability are critical,” Sahu explained.

This capability is revolutionising how tooling designers conceive channels for conformal cooling, air venting, and ejector systems, which are crucial to efficient thermal management and faster cycle times. Traditionally, these required long, multi‑step machining or assembly, but hybrid AM machining workflows now embed them directly into the tool body. The result is improved first‑pass yield, reduced trial iterations, and tooling that is lighter, stronger, and more durable, while cutting lead times from months to weeks.

Global Trends and Indian Industry Momentum

The global adoption of AM for tooling is well underway, with aerospace and automotive sectors leading real production applications and demonstrating reliability at scale. “Globally, additive manufacturing is already being used for real production in aerospace and automotive sectors, proving its reliability at scale. This global momentum has encouraged Indian manufacturers to invest and adapt. With initiatives like ‘Make in India’ and the presence of global capability centres, adoption is steadily rising. However, India must accelerate investment and skill development to compete with countries, such as China, that are moving rapidly in this field,” stated Sahu.

India is rapidly emerging as a significant player, bolstered by OEM growth and government initiatives. Yet, competition from more advanced markets underscores the need for focused investment and talent development to capture the sector’s full potential. Building capabilities in advanced alloys, hybrid manufacturing, and digital supply chains will be critical for Indian tooling firms to match global benchmarks and secure long‑term competitiveness.

Future Outlook: Materials, Machines, and AI-driven Automation

Industry experts foresee AM becoming a standard tooling practice within the next five years, driven by ongoing materials innovations and intelligent automation. “Within the next five years, additive manufacturing will become standard practice in tooling. New materials with mechanical properties close to tool steels, multi-material and hybrid machines, and AI-driven automation will further advance tool room capabilities,” Sahu said. He emphasised that “the new generation of engineers trained in additive design will redefine what tooling can achieve”.

Kumar added that “continuous innovations in materials and printing speed will increasingly extend additive manufacturing beyond prototyping into end-use part production.” He further noted that “as more OEMs expand in India, the ecosystem will scale up rapidly to meet the growing demand and strengthen the country’s position in global manufacturing”.

Agam observed that “additive manufacturing is moving toward a smarter, faster, and more integrated future”. He elaborated that “the coming wave will be defined by advanced materials engineered for strength and temperature resistance, automated and connected production systems, and AI-driven process intelligence,” which together “will elevate tooling from a preparatory step to an enabling force for agile, localised, and sustainable manufacturing”.

Machine learning and AI-enabled process intelligence promise to optimise build parameters in real time, ensuring consistent part quality, while multi-material printers will bring unprecedented design freedom, manifesting tools that combine durability with complex functional gradations unseen before.

This article was published in TAGMA Times

COMMENTS