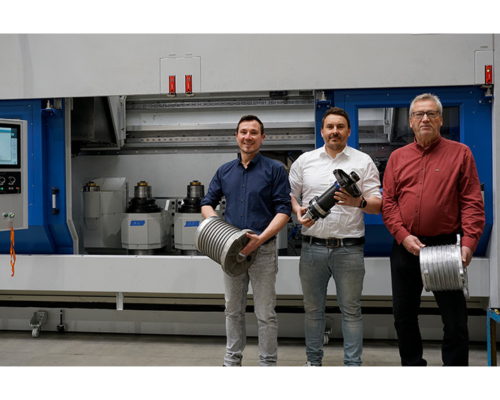

A process developed by Chemnitz-based machine manufacturer NILES-SIMMONS and toolmaker MAPAL for the complete machining of stator housings for electric motors has now entered series production.

In a joint development project, the two companies demonstrated that highly cost-efficient and precise production of stator housings can be achieved using a pick-up lathe. These thin-walled aluminium components, which feature external ribs for the cooling circuit, are used in the drive systems of electric vehicles and are installed within the larger motor housing.

During the development phase, NILES-SIMMONS used a converted modular lathe. Now, a machine specifically designed for stator housing production has been launched. This new machine is based on the vertical machining centre from the RASOMA brand, which, like NILES-SIMMONS, is part of the NSH Group (NILES-SIMMONS-HEGENSCHEIDT GmbH). Both brands operate under the NSH Group subsidiary, NSH TECHNOLOGY, and jointly advanced the machine’s development. The model, RASOMA DZS 400-2, features two workpiece spindles.

For series production, the machine includes side-mounted pick-up and drop-off areas for raw and finished parts, respectively. Components are fed and removed via conveyor belts. When operated manually, automation allows for a buffer of ten to twenty parts, enabling one person to manage multiple systems while performing additional tasks. “We have implemented a highly simplified automation as standard. No robots or additional equipment on the machine are required. Operators can place parts directly on the pallet belt,” says Thomas Lötzsch, Sales Manager at NSH TECHNOLOGY. An optional fully automated system for loading and unloading multiple machines using a central conveyor is also available.

The machine is designed for easy integration into existing production setups, thanks in part to its compact footprint of 7.50 x 2.60 meters. The design of the RASOMA DZS 400-2 was developed in collaboration with LTH Castings, a long-standing partner experienced in casting and machining complex, high-quality, thin-walled components made from pressure die cast aluminium. As a result, the design directly reflects practical industry experience and user needs.

Complete Machining in Two Clamping Operations

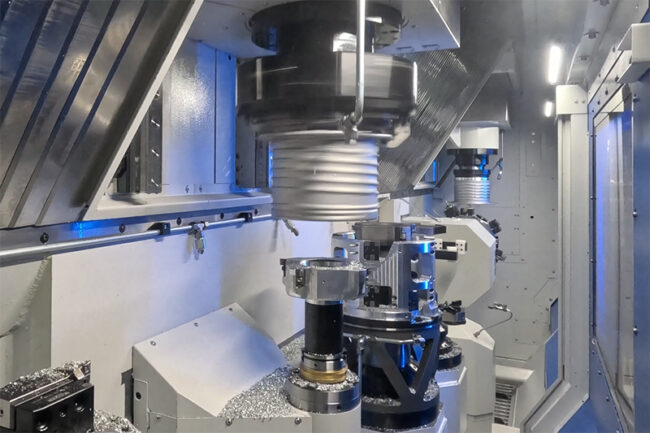

Between the pick-up and drop-off stages, the complete machining of the components is carried out on the vertical machine using two clamping operations. Initially, a clamping device picks up the workpiece from above and sequentially moves it through various machining stations within the machine. At a re-clamping station inside the working area, the part is rotated 180 degrees and transferred to the second workpiece spindle for final machining. While the second spindle finishes the current part, the first spindle begins processing the next one.

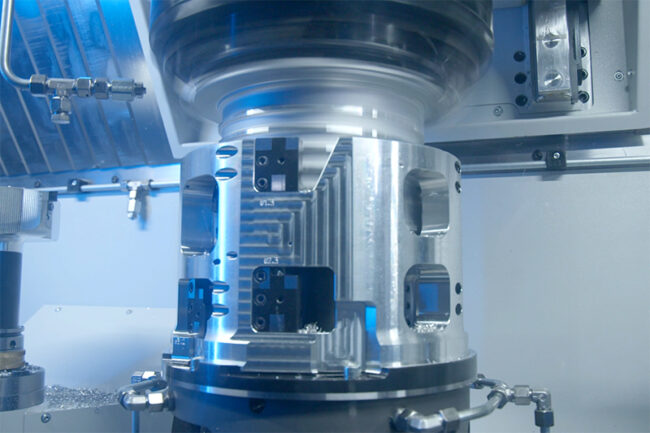

The machining operations proceed in sequence, resembling a compact transfer line. The process starts with pre-roughing various internal diameters of the component. In this stage, the tool remains stationary while the workpiece rotates. “Compared to conventional turning with a blade, machining with a four-blade ISO boring tool on an HSK-A 100 spindle reduces productive time to just a quarter,” explains André Ranke, Regional Sales Manager at MAPAL. The next step involves simultaneous internal and external machining of the rotating stator housing, using four blades each. The internal tool also rotates, and the difference in speeds between the tool and the workpiece generates the cutting speed for the inner blades.

The bell-shaped outer tool stands still. The component is placed in the gap between the inner and outer tool for machining. This patented process reduces forces that occur on the clamping system. This makes it possible to avoid using a complex workpiece clamping device with vibration damping for precise machining of the thin-walled components. “When designing the tool, particular attention was paid to the large chip volume and the significant forces generated, as it is unusual for the inner and outer diameters to be machined simultaneously”, explains Michael Kucher, Component Manager E-Mobility at MAPAL.

During finishing, only the fine boring tool is driven, while the component stands still. This prevents workpiece shapes that are not rotationally symmetrical from causing imbalances in the material and having a negative impact. The workpiece is then reclamped in the machine and the outer area that was previously clamped in the flange area is machined. The re-clamping station can also be used for another purpose: the workpiece is placed here before fine boring to relax the material. The machine has two tool revolvers for driven tools that carry out further machining based on component requirements.

Faster and more stable than expected

“The bottom line is that the RASOMA DZS 400-2 brings together the best of both worlds: the turning speed for pre-machining inner and outer contour with the accuracy of fine boring for finishing the inner contour”, says Daniel Pilz, Project Leader at NSH TECHNOLOGY. The machine tool manufacturer and MAPAL contributed their respective core competences to this complete solution. With the serialisation of the machine, tool technology and process, the positive results of the prototype were improved even further. The process reliability achieved even exceeded expectations, allowing the targeted cutting speed of 700 m/min to be increased even further. “For this aluminium machining, the experience NILES-SIMMONS brings from the diversity of technology has a positive impact on the overall reliability of the tool technology and machine”, explains Michael Kucher, Component Manager E-Mobility at MAPAL.

The RASOMA DZS 400-2 achieves a much shorter chip-to-chip time than a milling centre. This is because all tools are already in the working area and are only brought into working position by swivelling the revolver disc. This does away with all tool changes, reducing non-productive time substantially. Using this technology, a cycle time reduction of 50% versus standard turning was already anticipated in studies. During process optimisation, cutting speeds of 1,000 m/min were achieved using optimal cutting material. The additional optimisation of non-productive time resulted in even more time saving of 20%.

The process is so reliable that random sampling is sufficient for quality assurance. While all manufactured components were measured at first, the current recommendation is just one part per shift. Daniel Pilz uses figures to demonstrate that this is more than satisfactory: “The RASOMA DZS 400-2 with the special tools from MAPAL achieves a process capability index of over 1.67 for critical characteristics, such as cylinder shape, diameter and concentricity and thus meets industrial specifications.” Customers for whom the machine is already in use achieve an annual output of up to 180,000 components produced in three-shift operation.

Proven Performance in High-Volume Production

LTH Castings in Slovenia is among the first to implement the serial production process for stator housings using the RASOMA DZS 400-2. With a long-standing history in casting, the company operates more than 100 casting cells and processes raw components on over 250 CNC machining centres. Across its six locations, LTH Castings employs approximately 3,800 people. Dr. Primož Ogrinec, CTO of LTH Castings, said, “With our all-in-one solutions from the design to series production, we are a key strategic partner for the automotive industry. Our range includes component for drives, motors for battery-powered electric and hybrid vehicles, steering and braking systems.” The RASOMA DZS 400-2 machines are loaded and unloaded by robots in the ultra-modern production.

Like most automotive suppliers, LTH Castings manufactures components for various vehicle models. The flexibility of the RASOMA DZS 400-2, in which only clamping devices and tools need to be re-tooled, is useful for the production of stator housings. “With a single system and using the new process, an optimum solution, manufacturer-specific in quantity and quality, was developed and brought to series production maturity”, says André Ranke. Stator housing production is therefore possible up to a diameter of 500 mm and a component length of 500 mm.

“Every kind of housing we’ve seen can be manufactured on the RASOMA DZS 400-2 – and we’ve seen plenty of them”, says Thomas Lötzsch. The project team also got a surprise when a major car manufacturer’s housing design required an indentation on the inside of the component. The sample component from MAPAL, specially designed and produced for the process design, did not present this challenge. Yet MAPAL very quickly had a joint solution ready with the NSH Group specialists: Instead of the tried-and-tested fine boring tool, an ultra-precise actuating tool with four slides from the MAPAL product portfolio was used to create the desired inner contour. On the machine side, a connection designed in coordination with MAPAL was ready in a few days. It already achieved series production maturity during the ongoing order. As their development structure is now tightly networked, the two companies are able to react quickly to newly developed contours.

New Standard for Low Cost per Part

The RASOMA DZS 400-2, combined with MAPAL’s tooling technology, has proven itself in series production, addressing quality challenges often seen with conventional turning, milling machines, and horizontal transfer lines. Thomas Lötzsch recounts instances where required shape and position tolerances could not be consistently achieved, leading to scrap rates of up to 50%. In cases where quality met specifications, long cycle times still resulted in high per-part costs. A reliable, standardized process for producing these components had previously been lacking.

As competition on price is tough among automotive suppliers, when the RASOMA DZS 400-2 was being developed, the focus was on keeping unit costs as low as possible from the outset. This goal was achieved with a combination of high machine availability, short cycle times, machined component quality and production with reliable processes. Current calculations indicate that machining, including tool costs, can achieve economical costs per part as a result.

COMMENTS