– Kimberley D’Mello

The demand for high-quality dies and moulds is rising sharply across sectors like aerospace & defence, automotive, electronics, consumer goods and medical devices. For Indian toolmakers, this presents a wealth of opportunities. By embracing advanced machining, digital design tools, and automation, Indian toolmakers can not only meet the rising domestic demand but also position themselves competitively in global markets—transforming challenges into growth prospects and technical expertise into a strategic advantage.

Every vehicle on the road, every smartphone in your hand, and every appliance in your home relies on a critical yet often overlooked industry: the die and mould industry. Dies and moulds form the foundation of modern manufacturing. Together, they empower manufacturers to produce large volumes of uniform parts with exceptional speed, accuracy, and consistency. In India, this industry is experiencing significant growth. Today, it positions itself as a vital contributor to the nation’s aspirations of becoming a global leader in manufacturing excellence.

Industry Trends and Growth Drivers

India’s rapidly growing automotive, aerospace & defence, electronics, and medical device industries are driving domestic demand for high-quality dies and moulds. These industries require precise and even tiny, intricate components, necessitating sophisticated die and mould solutions. As products get more

complex, manufacturers are investing in technologies that can meet these needs. For instance, electric vehicles require lightweight and efficient components, which is driving up demand for specialised dies and moulds.

Another factor is customisation. Customisation is driving growth in the die and mould industry. With the rising demand for personalised products, manufacturers are using flexible tools to quickly design and adapt dies and moulds. This ability to meet customer preferences efficiently is helping businesses stay

competitive and expand their market presence.

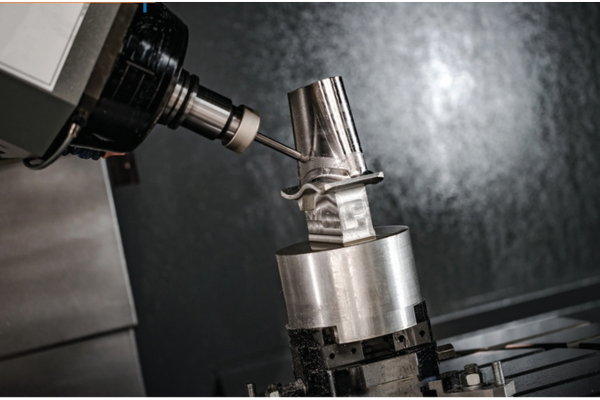

Technology is also reshaping the die and mould industry. The adoption of advanced technologies, such as CNC machining, CAD/CAM systems, and 3D printing, is transforming the capabilities of Indian toolmakers. These innovations are enabling higher levels of precision, speed, and complexity in production processes. Furthermore, tools like IoT and AI are helping manufacturers improve efficiency, cut costs, and produce better-quality dies and moulds. The shift towards Industry 4.0 practices— such as real-time monitoring, automation, and data-driven optimisation—is revolutionising how dies and moulds are designed and manufactured.

Simulation is also revolutionising the way the die and mould industry works. Instead of relying on trial and-error or lengthy prototyping, toolmakers can now test their designs virtually—before even cutting the f irst piece of metal. This not only saves time and money but also helps catch potential flaws early, like material defects or cooling issues, leading to better-performing tools and more reliable products. As customer demands grow more complex, especially in sectors like aerospace & defence, automotive, and medical devices, simulation gives manufacturers the confidence to take on challenging projects. It also f its perfectly into the push towards smarter, more connected factories by supporting digital twins and seamless integration with CAD/CAM tools.

Additionally, the Indian government has introduced the Production-Linked Incentive (PLI) scheme, among other initiatives, that could boost MSMEs in the die and mould industry. These programs provide financial incentives and encourage investments in domestic manufacturing and research and development. By fostering a supportive ecosystem, these policies are strengthening the foundation for sustained growth.

Localisation is also significantly driving the growth of the die and mould industry in India. It reduces import dependency, lowers costs, and improves turnaround times for manufacturers across sectors like automotive, electronics, packaging, and aerospace & defence, which are driven by the growing need for self-reliance. Besides, multinational companies setting up manufacturing facilities in India are leveraging these benefits and are increasingly sourcing dies and moulds locally.

How the Industry is Overcoming its Challenges?

Despite its strong growth trajectory and strategic importance, the Indian die and mould industry faces several challenges. Let’s understand these challenges and how they could be tackled:

Workforce Shortage: The shortage of skilled die and toolmakers is a major challenge for the industry. As experienced professionals retire, there aren’t enough younger, trained professionals entering the workforce to replace them. This talent gap affects productivity, innovation, and long-term growth. To bridge this gap, industry stakeholders must invest in robust skill development programs. Collaborations between industry bodies, vocational training institutes, and engineering colleges can help create structured apprenticeship programs. Upskilling existing workers through short-term technical courses, hands-on workshops, and exposure to modern tooling technologies will also ensure knowledge transfer and workforce readiness.

Technology Gap: Many Micro, Small, and Medium Enterprises (MSMEs), which form the backbone of the tooling sector in India, struggle to adopt advanced machinery like CNC machines, EDMs, and digital design tools due to high upfront costs and limited resources. The government and industry associations can step in with targeted financial schemes such as subsidised loans, tax incentives, and technology upgradation funds. Creating shared technology centres or clusters where smaller players can access high-end machinery without full ownership can also accelerate modernisation while minimising financial risk.

Lead Times: With global customers expecting faster turnaround, long lead times have become a significant bottleneck. Delays can erode customer trust and hurt future business opportunities. Implementing lean manufacturing practices, automating design and production workflows, and improving supply chain efficiency are key. Adopting digital tools like ERP systems and real-time production monitoring can help manufacturers plan better, reduce idle time, and streamline operations.

Opportunities for Toolmakers: As India’s die and mould industry grows rapidly, it opens up a world of opportunities for toolmakers ready to evolve with it. By sharpening their skills, embracing automation, and staying ahead of the tech curve, Indian toolmakers can not only thrive—they can lead. Here’s how:

Specialise and Upskill for a Precision-Driven Market: Modern tooling is all about precision—and CNC machining is at the heart of it. Toolmakers who invest in advanced techniques like 5-axis machining can handle the intricate geometries needed in today’s high-performance moulds and dies. Whether it’s injection moulding for electronics or stamping for auto parts, possessing CNC skills will offer toolmakers a competitive edge.

Understanding Advanced Materials: Toolmakers who understand the strengths and characteristics of materials like alloy steel, ductile iron, or specialised resins can design tools that last longer and perform more effectively. Material know-how ensures the right choice for the right application.

Designing Smarter Tools: The ability to design smarter tools using CAD and simulation software is important. As the demand for progressive dies and multi-cavity moulds continues to rise, having a good grasp of tooling design principles will allow toolmakers to reduce errors, speed up development cycles, and offer solutions tailored to mass production needs.

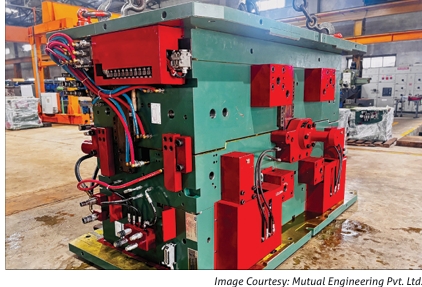

Hard Tooling for High Volumes: Automotive and white goods industries need tools that can handle millions of cycles. Specialising in hard tooling will allow toolmakers to serve these high-volume needs with long lasting, precise dies.

Embracing Automation: The industry is leaning into automation to stay competitive. Toolmakers who integrate robotic systems, automated loading/unloading, and smart inspection can boost productivity while keeping costs in check.

Prototyping and 3D Printing: Technologies like rapid prototyping and 3D printing are enabling toolmakers to speed up development and respond quickly to customer needs. These techniques are especially useful for creating test moulds or short production runs, giving manufacturers the flexibility to innovate and iterate with less downtime.

Cost-Efficient Manufacturing: Efficiency is key. By optimising machining strategies, minimising tool wear, and streamlining workflows, toolmakers can deliver top-notch results at competitive prices. Here, implementing lean principles can benefit toolmakers as well. Implementing lean principles helps reduce waste, improves turnaround time, and streamlines operations.

The Road Ahead

As India aspires to become a global manufacturing powerhouse, the die and mould industry will play a foundational role. With strategic investments in skills, technology, and infrastructure, India has the potential not just to meet domestic needs but to emerge as a world-class hub for precision tooling. The future of Indian manufacturing will be shaped—quite literally—by the strength of its dies and moulds.

Images used for representation only. Courtesy Envato Elements.

This article was published in TAGMA Times

COMMENTS