In an era where global automakers demand precision partners capable of fueling electric vehicle revolutions and smart manufacturing, India’s die & mold sector which is long celebrated for its artisanal craftsmanship and cost advantages, stands at a pivotal crossroads demanding urgent transformation.

–Ajit Gupta, SGM, Nagata India and Sanjay Chavre, Advisor TAGMA India.

The industry, a cornerstone of automotive components, plastics, and consumer goods production, must swiftly integrate digital design tools, cutting-edge metallurgy, hybrid manufacturing techniques blending additive and subtractive processes, and advanced metrology for quality assurance to elevate itself from mere supplier to indispensable technology ally for international OEMs worldwide. This shift is not optional but essential, as rising complexities in high-volume molds for EVs, electronics, and packaging expose the limitations of traditional methods amid intensifying global competition and supply chain pressures.

Current Practices in Indian Die Production

Indian small-scale die manufacturers primarily rely on conventional machining and limited CNC technologies, facing challenges in precision, material quality, and capital investment.

Small-scale units in India engaged in die manufacturing typically use a mix of manual and semi-automated processes such as milling, turning, grinding, and shaping, often supported by lathe machines, surface grinders, EDM (Electrical Discharge Machining), and basic CNC machining centers. These units frequently operate tool rooms equipped with VMCs (Vertical Machining Centers), conventional lathes, and welding setups to produce forging dies, trimming tools, and punches. However, they face persistent challenges including limited access to high-end CAD/CAM software, inadequate precision due to older machines, and difficulty in maintaining die quality under high thermal and mechanical stress. Moreover, high costs of tool steel, lack of skilled manpower, and restricted capital for upgrading to advanced technologies like 5-axis CNC or additive manufacturing hinder their competitiveness. Despite these constraints, many are gradually adopting digital solutions and lean manufacturing practices to improve productivity and meet evolving industry demands, especially with the rise of EVs and automation in manufacturing.

Evolution of Die Manufacturing in India

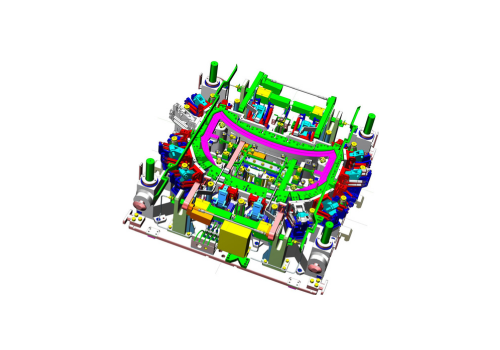

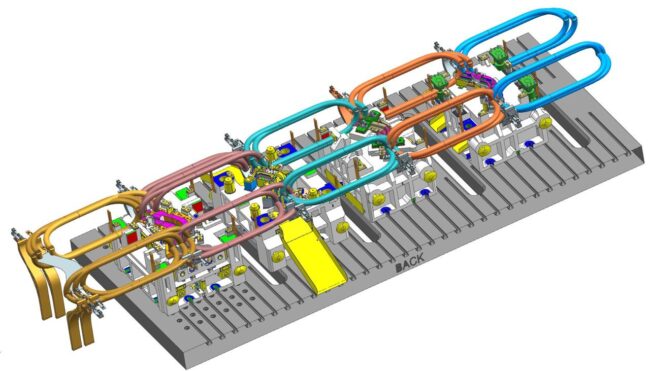

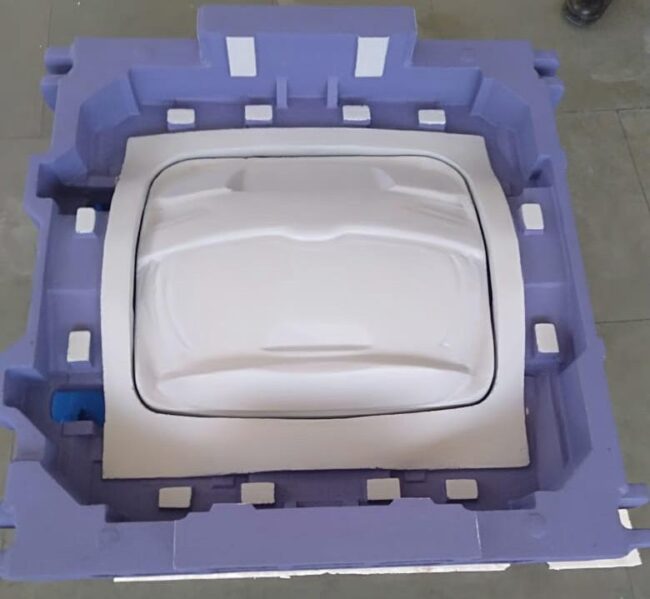

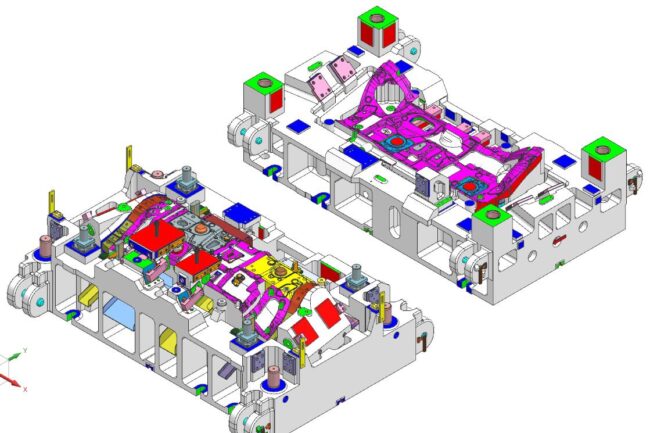

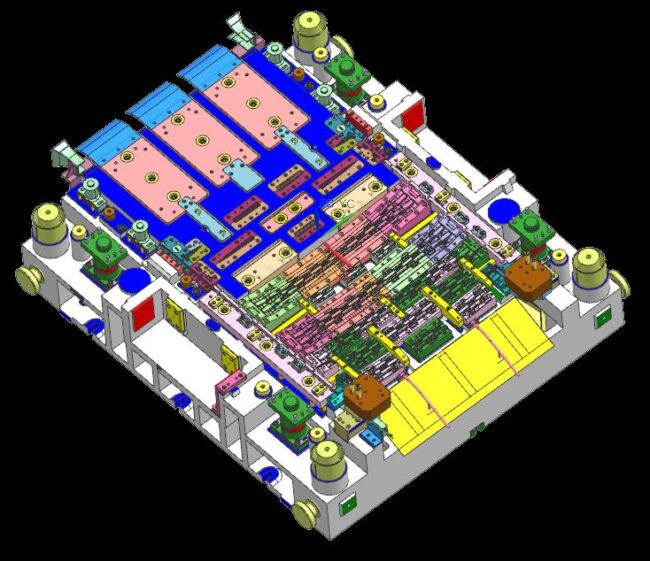

Die manufacturing in India has evolved into a precision-driven, technology-intensive process. Modern die makers employ CNC machining (3-axis to 5-axis) for high-accuracy milling and turning, Electrical Discharge Machining (EDM) for intricate cavity shaping, and CAD/CAM software for design and toolpath generation. 3D simulation and die confirmation are increasingly used to validate designs before production. Materials like high-performance tool steels and aluminum alloys are selected based on application including automotive, electronics, packaging, or plastics.

Processes typically begin with digital design, followed by rough machining, heat treatment, and finishing operations like grinding and polishing. Laser cutting, robotized polishing, and deep-hole drilling are used for complex geometries. Some manufacturers also integrate 3D printing for prototyping or hybrid tooling.

Leading firms like Phillips Machine Tools and RSTools India offer turnkey die solutions, serving sectors from automotive to consumer goods. The emphasis is on tight tolerances, repeatability, and surface finish, with increasing adoption of Industry 4.0 practices like IoT-enabled monitoring and predictive maintenance.

Challenges in Die Manufacturing in India

Despite technological progress, India’s die manufacturing sector faces several structural and operational challenges. A major issue is dependence on imported tooling components, especially high-grade steels and precision inserts, which increases costs and lead times. Skill shortages in advanced die design, CNC programming, and limited common facilities for outsourced heavy investment services, simulation limit scalability and innovation.

Fragmentation of the industry with many small and medium enterprises lacking access to capital and modern infrastructure hampers consistency in quality and delivery. Inadequate R&D investment and limited collaboration between academia and industry slowdown the adoption of cutting-edge technologies like additive manufacturing and AI-driven process optimization. Regulatory complexity, especially in environmental compliance and labor laws, adds to operational burdens. Supply chain vulnerabilities, exposed during global disruptions, affect raw material availability and logistics. Additionally, lack of standardisation in die design and performance benchmarks leads to inefficiencies and rework.

To remain competitive, Indian die makers must invest in automation, skill development, and digital integration. Government initiatives like ‘Make in India’ and PLI schemes offer support, but sustained growth will require strategic partnerships, technology transfer, and cluster-based development models.

The Digital Thread: From Art to Science

The gap between traditional practices and global best practice starts long before chips are cut: it begins in the software toolchain.

- Generative design & topology optimisation:

Software can propose materially efficient die structures based on loads, thermal constraints, and manufacturability rules. This reduces mass, improves stiffness, and shortens cycle times. - CAE is indispensable:

Use Moldflow-style analysis for plastics and AutoForm/PAM‑STAMP/LS‑DYNA for forming to predict thinning, springback, and warpage, and incorporate compensations directly into CAD models. - Digital twin & process control:

A living digital model, fed by real-time sensor data, enables closed-loop optimisation, predictive maintenance, and rapid troubleshooting.

Advanced Manufacturing Technologies: Beyond 3-Axis CNC

These specialised methods leverage high-speed strategies, multi-axis precision, additive innovations, and enhanced EDM for superior efficiency and complex die production

- High-Speed Machining (HSM):

Combine trochoidal toolpaths, HSK spindles, and optimized CAM to achieve superior finish and shorter cycle times. - 5-Axis simultaneous machining:

Reduces setups and eliminates re-fixturing errors, enabling complex contours to be finished in a single run. - Additive manufacturing for conformal cooling:

Laser powder bed fusion enables coolant channels that follow cavity contours for uniform cooling and cycle-time reductions. - EDM advances:

Adaptive power supplies, submerged machining, and automated threading support unattended high-accuracy operations.

Materials Science and Heat Treatment

These techniques emphasize material selection, advanced heat treatment processes, and surface enhancements critical for enhancing die durability and performance in demanding applications

- Right steel for the job:

Choose hot-work, cold-work and mold steels (ESR/PM grades where needed) based on temperature, abrasion, and polishability. - Vacuum heat treatment:

Vacuum hardening and gas quenching reduce oxidation and decarburization while minimizing distortion; this often removes the need for heavy post-HT machining. - Surface engineering:

PVD/CVD coatings like AlCrN, TiAlN and DLC extend die life in high-temperature or corrosive environments.

Organisational & Ecosystem Barriers in India

These barriers highlight cultural shifts, skill development needs, and financing strategies essential for overcoming limitations in India’s die manufacturing ecosystem.

- Culture: Complement ‘jugaad’ with data-driven engineering using CAE and telemetry.

- Skills: Build vocational programs and industry partnerships to upskill technicians for 5-axis, AM and CAE roles.

- Financing: Frame capital equipment as strategic investments with measurable ROIs.

Strategic Imperatives: A Roadmap for Indian Die Makers

These key strategies outline essential steps for specialization, technological integration, quality assurance, process formalisation, and sustainable practices to elevate Indian die makers in the global market.

- Specialise & climb the value chain: Focus on high-cavity PET preform molds, micro-molds, or large hot-stamping fixtures.

- Embrace hybrid workflows: Combine AM inserts with 5-axis finishing.

- Invest in metrology: In-process probing, CMMs, laser/structured-light scanning, and optical comparators.

- Formalise and document: SOPs, version-controlled CAD/CAM libraries, and digital twins.

- Sustainability & efficiency: Use induction heating, efficient vacuum quenching, and simulation-driven design to reduce energy use and scrap.

Conclusion

A climate-controlled shop where a generative CAD model feeds a digital twin, a DMLS conformal-cooled insert sits next to a 5-axis HSM, and a final die leaves with CMM validation represents the future. Indian die makers can transition from job-workers to strategic technology partners by investing in processes, people, and precision tools. This vision aligns with market growth projected at a CAGR of 11.4% through 2029, fueled by PLI schemes, EV demand, and Industry 4.0 adoption, positioning the sector for global leadership amid technological and sustainability shifts.

About the Author

Sanjay Chavre is Advisor to TAGMA India.

A respected technocrat and policy strategist, Mr. Chavre has been a pivotal figure in the evolution of India’s manufacturing and tooling ecosystem. With decades of experience at the intersection of government and industry, he has contributed to the development of forward-looking policies that promote indigenous technology, strengthen domestic capabilities, and uplift MSMEs within the tooling and precision engineering sectors.

Mr. Chavre has held key roles in various government departments. He has been instrumental in formulating and executing initiatives that align with India’s long-term vision for industrial growth and self-reliance. His expertise lies in enabling public-private collaboration, fostering innovation ecosystems, and building frameworks that support sustainable industrial development.

In his current role as Advisor to TAGMA India, he continues to guide efforts aimed at enhancing the global competitiveness of Indian toolmakers. His insights have been vital in positioning the Indian tooling industry as a reliable and technologically advanced partner in the global supply chain.

COMMENTS