durcrete GmbH, a specialist in cement-bound mineral casting for mechanical engineering, has developed a groundbreaking ultra-high-strength casting compound, ‘durfill E’, in collaboration with Dyckerhoff GmbH. The “E” signifies increased modulus of elasticity—over 65,000 N/mm²—the world’s highest modulus of elasticity for mechanical engineering, enabling significantly reduced machine deformations and drastically increased natural frequencies. This makes it particularly advantageous for modern applications such as test benches in e-mobility.

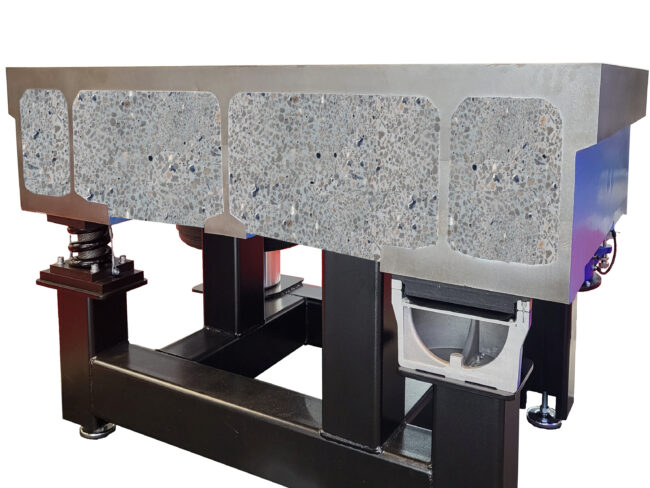

For over 15 years, durcrete GmbH has supplied machine tool manufacturers with vibration-damping machine beds made of cement-bonded UHPC (Ultra-High Performance Concrete). With ‘durfill E’, the company sets new standards for cement-bound dry-mix mortars, achieving a modulus of elasticity far exceeding that of conventional materials used in mechanical engineering. The innovative binder NANODUR from Dyckerhoff GmbH ensures that the product maintains its high deformation resistance even at temperatures up to 90°C.

Ease of Use at the Forefront

durfill E is designed for simple handling, retaining the ease-of-use features of its predecessor, durfill S. The ready-to-use dry mortar allows uncomplicated mixing, self-compacting pourability, easy cleaning with water, and hassle-free disposal of residues. Tested thoroughly by certified laboratories, durfill E is exclusively tailored for mechanical engineering applications.

Ideal for High-Speed and Precision Applications

The shift to e-mobility has introduced electric drives and gearboxes with speeds up to 30,000 rpm, placing greater demands on test tables, frames, and rigs. Traditional cast iron components often struggle with resonance, leading to chatter marks and inaccurate measurements. durfill E enables upgrades of existing gray cast iron constructions directly in the factory, offering both economic and time efficiency.

Beyond high-speed applications, durfill E is suitable for highly stressed, filigree, thin-sheet metal constructions, where the steel shell is minimized, and for local anchoring of screw connections and precision surfaces. Its combination of high natural frequency, rigidity, mechanical and thermal inertia, and excellent damping makes it ideal for precision machinery and demanding mechanical engineering applications.

durcrete GmbH will be showcasing durfill E and its advanced mineral casting solutions at EMO 2025, highlighting its commitment to innovation, precision, and high-performance materials for the modern mechanical engineering sector.

COMMENTS