The metal forming simulation tool with a practical focus for economical productivity is finally here. Dynaform 7 adds a powerful new Die Face Design module, allowing for easy and intuitive die-face creation. Engineers can quickly simulate and evaluate designs for a more reliable, efficient process that speeds up the estimation and tool-building process.

Die Design Made Easy

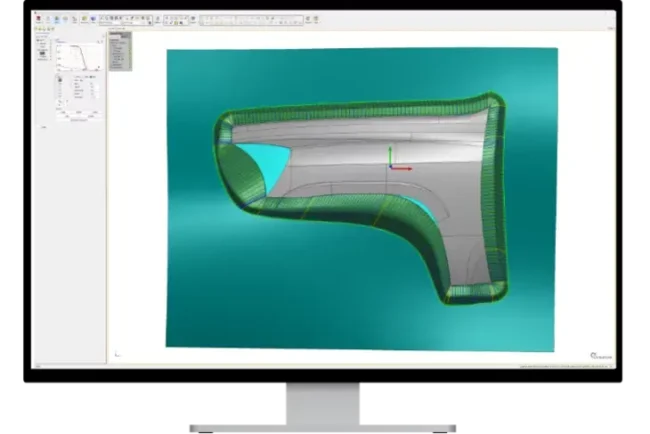

The complete die face engineering package facilitates tooling design by using the part geometry. Offers a NURBS surface-based infrastructure and interfaces with all major CAD codes to produce high quality CAD surfaces.

Automated tools minimize design work

Generate and finely tuned binder surfaces, addendum profiles/surfaces, PO line and layout draw beads using automated tools in CAD surface and CAE mesh environments. Minimize die design work with automated tipping, reverse trimming, undercut/draw depth calculation, fileting, and un-flanging.

Use part geometry for binder and addendum surface generation

Create, edit and morph binder surfaces using part geometry with the addendum generator. Create a series of profiles base on draw depths and part shape between the binder and the die cavity. Mesh and surface the profiles to create a complete addendum for forming, and edit using interactive functions or by adjusting the shape of the PO line.

Parametrically define addendum profiles

Addendum profiles are parametrically defined for quick adjustments by editing parameters

Associativity automatically extends changes

Parametrically defined surfaces and profiles mean binder surfaces, addendum profiles/surfaces and PO line are fully associated. Modify one entity and it automatically extends to the other entities.

Efficiency and profit-driving modules that Dynaform has delivered for 30 years

TBF / Tube Bending & Forming

Process setup and simulation for tube-bending and forming processes. Based on product geometry, TBF can automatically (or manually) setup tube-bending and hydroforming processes, generating tooling and validation processes.

- Automatic Bending Process

- Bending Table Tools

- Geometry & Automation Tools

- Center Line Calculation

Formability Simluation

Dynaform’s forming simulation software makes it possible to uncover design flaws early in the process. Using the various modules, engineers can more-fully evaluate alternative–and unconventional–designs. Doing so helps ensure higher-quality outcomes.

- Springback

- Springback Compensation

- Drawbead Optimization

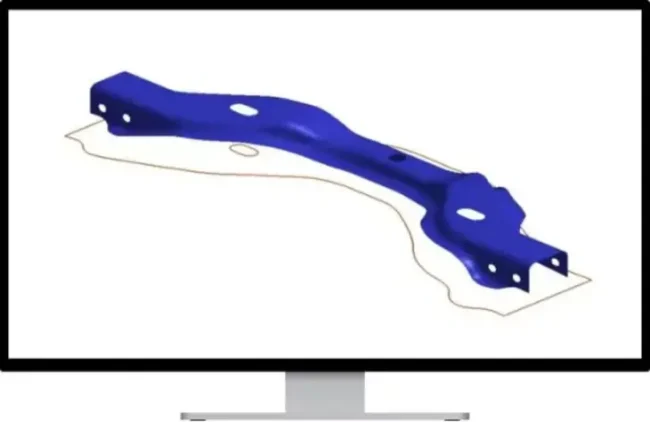

Blank & Trimeline Development

Determine a blank’s optimal shape and size before producing any physical parts. Accurately predict the deformation, thinning, and stretching that will occur during the forming process to determine the initial size and shape of the blank. Predict the final shape and contour of a part after trimming, ensuring that final part meets your specifications and quality standards.

- Automatic Iteration and Optimizations

- Industry Leading Accuracy

- Simple Setup Process and Interface

BSE / Blank Size Engineering

Process setup and simulation for tube-bending and forming processes. Based on product geometry, TBF can automatically (or manually) setup tube-bending and hydroforming processes, generating tooling and validation processes.

- Deep Drawing

- Line Die

- Progress Die Support

Your high-performing engineering teams can reach new levels of productivity

Tooling Designers

Experiment and fine-tune tooling is a way that saves time and cuts costs. Dynaform 7 allows you to try, evaluate and modify various scenarios before putting them into practice.

- Hit Your Deadlines

- Reduce Die Design Time

- The Right Die, The First Time

Estimators

Dynaform7 gives you transparent and fast insights that allow you to quickly and accurately estimate part production costs for feasible designs, including the expected rejection rate.

- Quickly Assess Project Feasibility

- Generate Quotes Quicker

- Reduce Project Timelines

Management

With clarity and a predictable process, you will be able to manage an efficient process and focus on building your business.

- Expand Marketshare

- Win More Bids

- Increase Profitability

COMMENTS