The poor level of demand in Europe is slowing down investment in the metalworking industry. However, this is also putting extra pressure on companies to stay competitive. That’s why it makes sense to explore solutions that deliver big results with small investments. Tool manufacturers acknowledge this fact and are developing ever more efficient solutions for their customers. At EMO 2025, visitors will get a chance to see these innovations in action. Exhibitors will show how users can boost productivity, precision, and tool life with minimal effort—helping them stay ahead in a tough market.

Four practical examples illustrate these advancements as listed below:

Short clamp holder with digital display increases productivity

Refining existing, proven solutions remains a powerful lever. This approach proves especially effective in scenarios like fine boring, where extremely tight tolerances demand utmost accuracy in tool setting. “Our 3E Tech+ digital readout coupled with the ES-Bore short clamping holder ensures higher productivity by reducing non-productive times. The display visualises the adjustment path with a reading accuracy of 1 µm in the diameter”, explains Axel Wagner, Business Development Manager at Wohlhaupter, located in Frickenhausen, Germany. This simplifies the setting process enormously, as there is no need for additional tools such as gauges. “For an in-line boring bar with five adjustment units, the setting time is reduced from an average of 10 minutes to less than one minute,” Wagner calculates by example. Another effect: the optimised Oled digital display rotates automatically like the display of a mobile phone – regardless of whether the tool is aligned horizontally or vertically. This is an advantage that should not be underestimated in narrow, dark machine rooms. And if the operator forgets to remove the display, it falls off automatically when the spindle starts turning, reducing the risk of accidents to zero. The short clamping holders are also available in an analogue version with a setting accuracy of 0.005 mm in diameter. The short clamping holders can also be used in special boring bars manufactured by customers themselves. Even existing tools in which short clamping holders with analogue adjustment are installed can be equipped with the digital short clamping holders. Visitors will be able to check this out at EMO 2025.

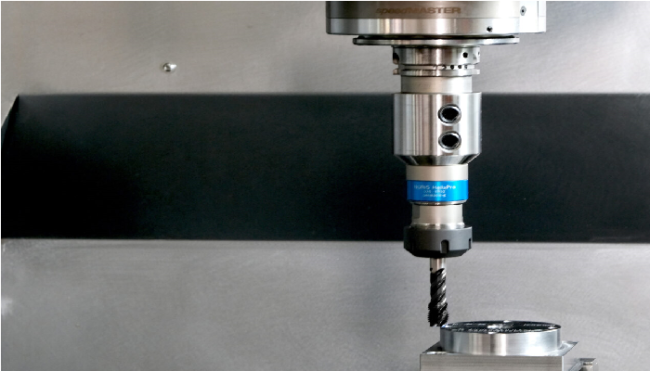

Tapping – change a running system!

According to Christoph Schneider, tapping is an optimisation opportunity that is all too often overlooked. The Product Manager at Reime Noris,Feucht, Germany, knows that the process, which is usually at the end of the production chain, often falls through the optimisation cracks. “According to the motto ‘never change a running system’, users like to rely on prooven processes. However, even small improvements to the tool holder can have a significant impact on tool life, process reliability and ultimately on the costs,” says Schneider. Depending on the process, users can more than double the tool life thanks to the recently developed tool holder paired with the powder steel tap. Especially the tool holder with minimum length compensation has a significant impact on product service life. The manufacturer’s engineers have succeeded in reducing the axial forces generated in the process, which significantly improves process stability and therefore increases tool life. The integrated collet chuck contains an elastomer that is slightly flexible which reduces the axial load on the tool to almost zero during thread cutting. “Due to modern materials, our customers’ machining requirements are constantly increasing. It is therefore important to be able to easily integrate process-improving solutions into everyday production,” explains Schneider. The optimised powder steel range will be the manufacturer’s focus at EMO 2025.

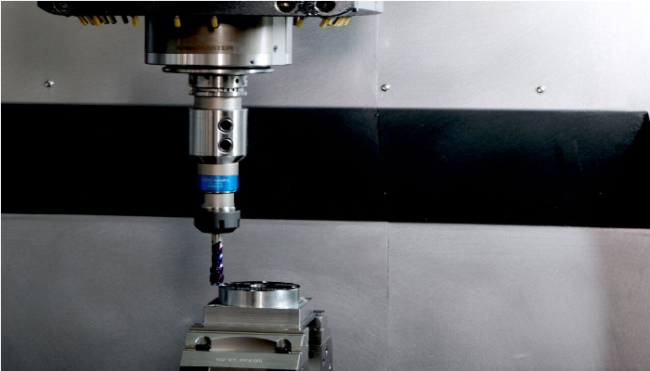

Three-edged boring head copes with all workpiece material groups

Conventional circular drilling and milling through pre-drilled holes can be slow and inefficient. This prompted Iscar, based in Ettlingen, Germany, to develop a new solution aimed at accelerating such operations. Their latest innovation is a flat drilling head featuring a triple-edged geometry that offers a new machining option—shifting the paradigm from circular milling to true drilling. This is because the new drilling head can machine existing holes, even if they are positioned off-centre – and this applies to all workpiece materials, including exotic ones such as ISO M, N and S. “Its geometry with a ground chip deflector produces very short chips during boring,” explains Patrick Muller, Product Manager Drilling at Iscar, adding: “This ensures high process reliability.” Doing so is crucial because, depending on the material, the chips can be too long to be safely removed during internal machining. And the geometry of the flat boring head can do even more: it triples the feed rate. This allows users to increase their productivity threefold, depending on the material to be machined. The Quick3Cham flat boring head can be used as a rotating tool for machining pre-cast bores or as a stationary tool on lathes. This solution will be the main focus for Iscar at EMO.

Reduce cost drivers – increase process reliability

For Tobias Stolz, Component Manager General Machining, Mapal, the entire production process is always under scrutiny. He focuses on identifying and reducing key cost drivers regardless for small batches or mass production. “We further develop the processes together with our customers on an industry-specific basis. After all, a supplier of hydraulic valves has different requirements to a car manufacturer,” reports Stolz. For example, the fluid technology specialists from Aalen have succeeded in achieving significant savings for a customer with medium series production in the complete process of drilling the valve gate in cast iron. Previously, the user needed three tools for machining the control edges and the deburring chamfers. Now, he can produce the deburring chamfers with just one combination tool. By reorganising the process, the user was able to reduce his manufacturing costs by 40 per cent – or 14,000 euros in figures – while producing 30,000 components per year. In addition, he also reduced his production time by 1,250 hours. ” Not only is the most economical solution important to us, but also process reliability,” says Stolz and adds: “To make our approach tangible, we will provide insights into various examples of best practice at EMO 2025 and guide our visitors to our solutions at the trade fair stand. Starting from the market segment in question, we lead you via your component to our solutions.”

VDMA Technology Forum from 23 to 26 September 2025

Once again, VDMA Precision Tools will be hosting its popular Technology Forum during EMO 2025. In short presentations from practice for practice, exhibiting members and research and development partners from the university sector will provide exciting insights into current trends in metalworking. The sessions will cover practical applications in machining and clamping, measurement and inspection technology, and digitalization.

COMMENTS