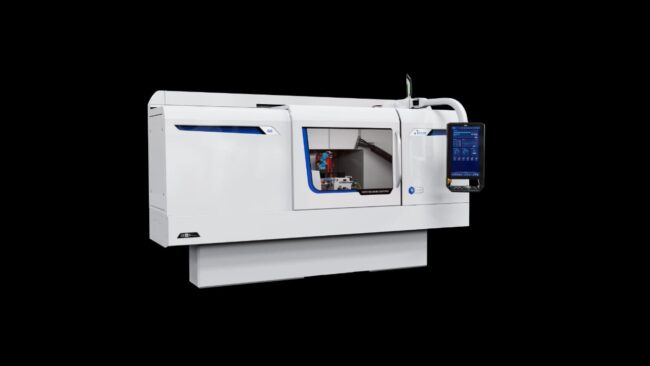

Fritz Studer AG unveiled the S23 universal cylindrical grinding machine at the EMO Hannover Trade Fair held in September 2025. Engineered for high precision, flexibility, and modern grinding technology, the S23 comes in a compact form designed to deliver exceptional performance.

Speaking about the launch, Sandro Bottazzo, CEO, Fritz Studer AG, said, “Thanks to its high-quality features, precision, and flexibility, the S23 complements our portfolio in the entry-level and premium segments.”

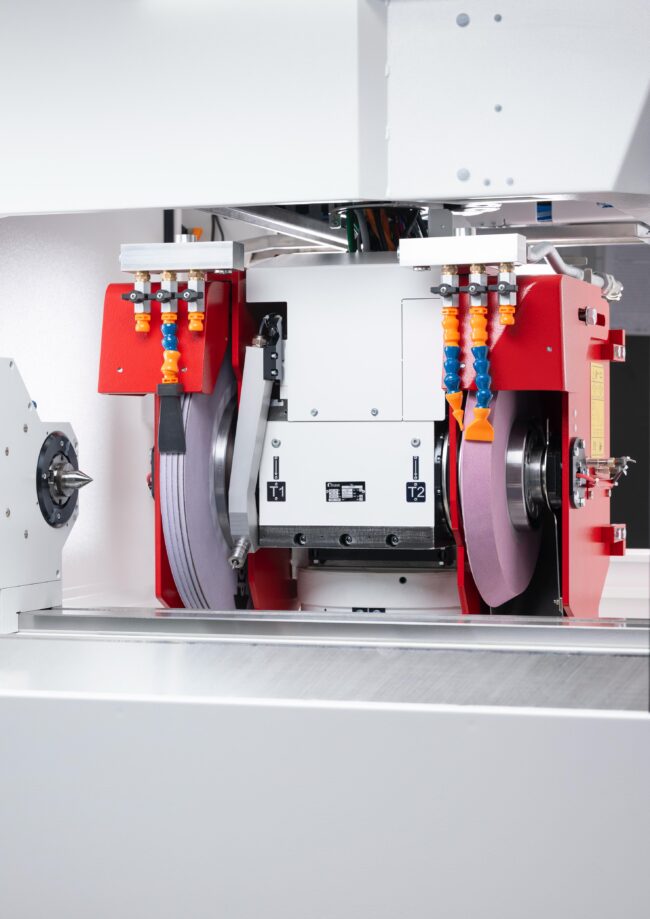

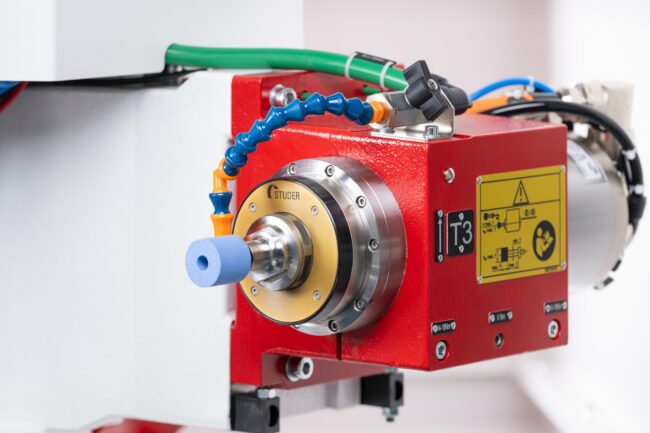

With its compact footprint, the CNC universal cylindrical grinding machine combines state-of-the-art technology with reliable performance. Among its advanced features are the modern C.O.R.E. hardware and software architecture, an automatic B-axis with 1° Hirth coupling for up to three grinding tools, frequency-controlled motor spindles or belt drives, and a machine base constructed from Granitan®, renowned for its outstanding thermal and vibration-damping characteristics.

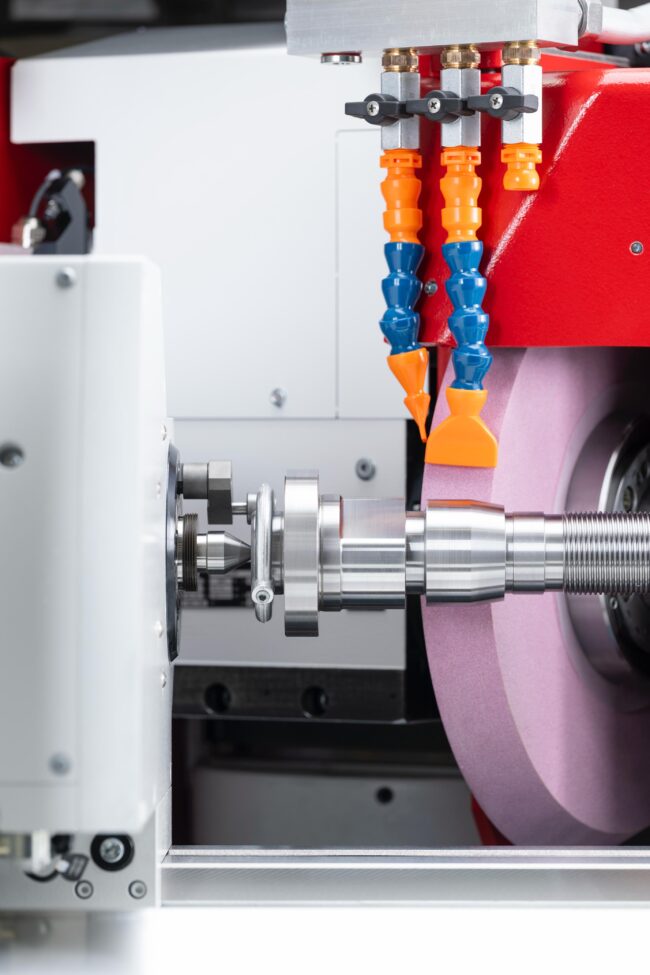

The S23 also brings significant customer benefits through its innovative design. The arrangement of the wheelhead provides enhanced versatility for grinding tools in a single clamping, which increases efficiency, particularly when working with geometrically complex workpieces. In addition, the machine integrates advanced grinding technologies such as contact detection, semi-automatic balancing of the external grinding wheel, and an optional in-process measuring system, all of which contribute to ensuring consistently high-quality results.

Optimal Solution for a Wide Range of Customers

This makes the S23 the ideal solution for a wide range of customers. With high accuracy and process reliability, it grinds small to medium-sized workpieces, even with complex geometries, in single and series production. “The S23 is ideal for production in the tool and die, automotive and supplier, aerospace, and in the medical technology industries,” explains Rolf Grossenbacher, STUDER Sales Manager. In addition, customers have numerous configuration options for adapting the machine to their individual production requirements. These include a C-axis for thread and out-of-round grinding and an optional swiveling table. Customer-specific adaptations are also possible.

Thanks to state-of-the-art digital technology and sensor technology, operation is simple and intuitive. After just a short introduction, employees can achieve reliable, high-quality results using the C.O.R.E. touch panel and StuderWIN software. Set-up and changeover times are also minimal, thanks to the practical QuickSet function. Customers who want to automate their production can do so efficiently and economically thanks to the standardized loader interfaces for easyLoad and insertLoad. And, of course, they benefit from STUDER’s worldwide competent customer care and the experience of a traditional Swiss company with over 111 years of history. “This makes the S23 a high-precision universal cylindrical grinding machine with an excellent price-performance ratio,” summarizes CEO Bottazzo.

The Advantages of the S23

- Compact design

- Distance between centers 650 mm / 1000 mm (29.6″ / 39.4″) and center height 175 mm (6.9″)

- Automatically swiveling wheelhead (B-axis) for two external grinding wheels and one internal grinding wheel or a production wheelhead

- Intuitive operation with C.O.R.E. and StuderWIN

- Standardized automation with STUDER easyLoad and insertLoad as well as customized solutions

You can find the product video here: New S23 Universal cylindrical grinding machine – YouTube

COMMENTS