This year, ZEISS is releasing a new version of the standard software for measuring technology on the market: ZEISS CALYPSO 2024 with many new features and improvements for different user groups. The software comprehensively analyzes the data from ZEISS coordinate measuring machines obtained with tactile and optical measurements and is continuously enhanced by the company at great expense. “Our customers expect a high level of precision combined with absolute reliability and increased performance. With our ZEISS CALYPSO software, we have been offering this for over 25 years,” explains Christoph Grieser, Head of Global Software Sales at ZEISS Industrial Quality Solutions. With the software, users have a strong partner in their back for the evaluation of data measured with ZEISS coordinate measuring machines.

PMI import comes with new GD&T library

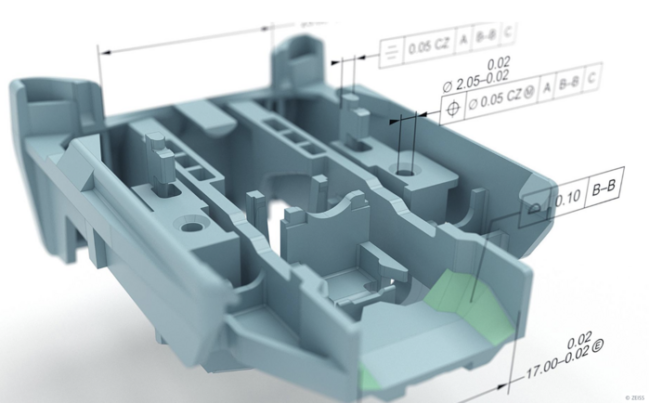

In CALYPSO 2024, users can use product and manufacturing information (PMI) to create inspection plans based on a new GD&T library. In the context of quality assurance, this means, for example, that the CAD model of a part is enriched with form and position tolerances. This information serves users as a tool for the generation of clear, repeatable, and comparable measuring results. Therefore, the combination of PMI and the new library in ZEISS CALYPSO makes it possible to work even faster and to be more productive.

Extensive improvements for the evaluation of optical measurements

Optical sensors are increasingly being used throughout the industry in combination with coordinate measuring machines – here, too, ZEISS CALYPSO supports the evaluation and analysis of optical data with its many functions. With the new reflection correction, the software increases the robustness of edge detection, for example, as the influence of surface finishing is reduced. In addition, the mosaic function provides users with a new way to create a large image from multiple small images, for example to identify large QR codes.

Enablement of 4-axis measurements

With this year’s release, ZEISS CALYPSO also supports the combination of ZEISS LineScan and a rotary table for 4-axis measurements. This reduces the number of positions required for the ZEISS RDS articulating probe holder. A reorientation of the sensor is not necessary, so that users can now perform measuring jobs faster and with increased performance.

ZEISS CALYPSO options enhanced

The powerful options that complement ZEISS CALYPSO are also being continuously enhanced and impress customers with their improved performance. This year, for example, with improvements in the measurement of connected curves with ZEISS CALYPSO curve and new filters for freeform surfaces in ZEISS CALYPSO freeform. “These and other enhancements speed up the measuring times and the entire analysis process,” explains Grieser.

In the field of gear metrology, users benefit from a new release of the ZEISS GEAR® PRO 2024 software. One of the highlights completes the evaluation possibilities for noise analysis on gear tooth flanks. With the order spectrum analysis, the actual-actual comparison, and the new color-coded topography visualization, including an evaluation of the helix angle of the waviness, the software now offers further powerful analysis tools for the e-mobility area.

With ZEISS CALYPSO, ZEISS has created a benchmark in metrology and is continuously expanding the product: “Whether these are minor tricks that can improve the evaluation process for our customers quickly and easily or brand-new functions, it is important to us that we improve the everyday lives of users and help take quality assurance to a new level,” says Grieser.

COMMENTS