HASCO has announced that its complete range of cooling elements is now available as digital CAD models, marking a step forward in supporting more efficient design and planning in mouldmaking. As design process optimisation becomes increasingly critical in modern mould construction, the move is aimed at helping designers and mouldmakers streamline project workflows and reduce development time.

With immediate effect, users can access digital CAD data for a broad selection of HASCO cooling systems, including Standard, High-temperature, Stainless steel, Push-Lok, ZI, Safety, French and Low-leakage variants. This extensive portfolio is designed to meet a wide range of technical and application-specific requirements across different mould designs.

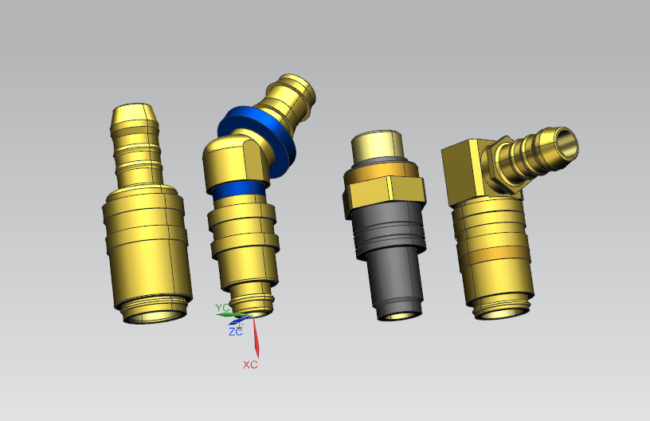

The newly released CAD models are highly detailed, providing clear visual guidance that supports intuitive selection and accurate integration into mould designs. By enabling seamless incorporation of cooling elements into existing CAD projects, HASCO aims to simplify planning processes and significantly accelerate the overall design phase for mouldmakers and design engineers.

The CAD data considerably reduce the amount of design work and the planning steps. The models guarantee precise, fault-free design, and at the same time offer maximum flexibility when adjusting to customised requirements. The time-consuming looking-up of technical data such as measurements and thread types becomes superfluous, which makes the overall design process not only faster but also more reliable.

From the very beginning, users benefit from a clear choice of all installation options and can take over the data directly into existing systems. This saves valuable time, minimises sources of error, and allows the forward-looking planning of complex moulds.

By offering the extensive cooling portfolio at CAD model level, HASCO has taken a further step in the direction of more efficient, flexible and reliable mould design. Users benefit from significant stress reduction, higher precision and an optimised workflow – genuine added value for modern mouldmaking and for everyone who, in the field of mould design, attaches importance to efficiency, quality and reliability.

COMMENTS