Spindle gear components are used in unscrewing tools to mechanically unscrew threaded cores. The HASCO gear components offer outstanding flexibility for mouldmaking and the concept and design of the unscrewing tool has been greatly simplified.

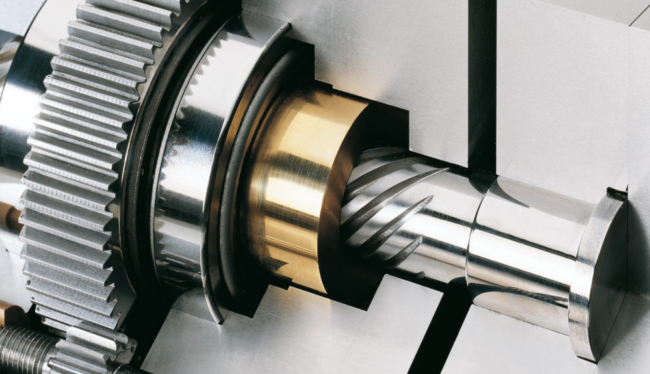

The extensive HASCO gear range Z1500/… contains a broad product spectrum of helical spindles, gear racks, thread cores, cogwheels and bearing and gear accessories that were developed specifically for use in unscrewing tools. All components are noted for their outstanding precision, proven quality and reliability.

The spindle gear components enable the mechanical unscrewing of thread cores and thus ensure efficient and smooth production. The drive comes from the mould opening, whereby simple handling and integration into existing systems are guaranteed. The innovative and high-quality solutions offer an optimisation of the production processes and increase competitiveness.

Various sizes of the intermediate wheels allow a variety of individual applications and solutions. With the gear shafts, steps between the individual modules can be readily implemented. Via the adjusting washers, width tolerances in the boring boss can be offset without problem. Cylindrical roller bearings and needle bearings, which are specifically coordinated to the diameters of the thread cores, allow high load capacity and life expectancy, despite their low installation height.

As a pioneer for mouldmaking and a leading international supplier of standard mould units and accessories, HASCO offers, with a product portfolio of more than 100,000 individual components, innovative solutions to optimise production processes and increase efficiency in mould and toolmaking. With a comprehensive range of services, starting with the initial consultation through to the final delivery, the HASCO technical service department helps customers throughout the world with the design and final testing of their projects.

COMMENTS