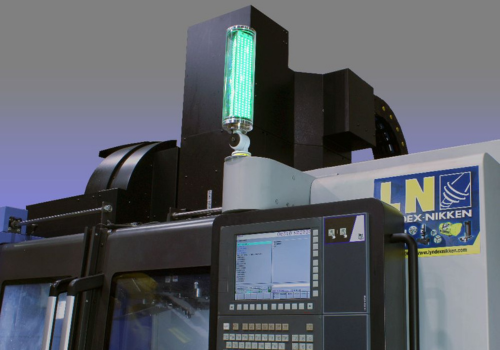

Lyndex-Nikken has introduced the EZ-SmartTower, a new machine tracking solution designed to help manufacturers improve shop-floor efficiency by simplifying return-on-investment analysis for machine tools.

Developed in response to ongoing challenges such as skilled labor shortages and fluctuating operating costs, the EZ-SmartTower enables machine shops to monitor equipment performance and utilization in real time. The system delivers actionable machine analytics that support data-driven decision-making and productivity optimization, while requiring no specialized expertise to deploy or operate. Positioned as a practical step toward Industry 4.0 and Industry 5.0 adoption, the EZ-SmartTower allows manufacturers to gain clearer visibility into machine performance and overall operational efficiency.

The EZ-SmartTower enables machine shops to seamlessly monitor and analyze production data of up to 30 machines from a single, centralized computer. With its modular and scalable design, the solution integrates effortlessly with CNC lathes, mills, and other machinery. It accurately logs machine cycle counts, records idle, cycle, and error times for spindle efficacy tracking, and captures operator, machine, and part data for comprehensive analytics.

Real-time monitoring is made easy with LED indicators displaying current cycle and idle times, while WiFi connectivity enables data transfer in real time. The leveraging of real-time data helps to reduce bottlenecks, improve spindle utilization, and enhance overall efficiency.

Through easy-to-use and free EZ-SmartTower software, users can generate reports in charts or Excel format for detailed analysis, providing valuable insights into shop performance and operational trends. Data in the App is internal to machine shop users and NOT transferred or stored over the cloud which is important for the security of the data.

While real-time machine status updates allow operators to make on-the-fly informed decisions to enhance workflow efficiency; data-driven insights help track performance and provide employee incentives based on productivity metrics. Ultimately, the analysis of machine and operator performance empower the cost-effective measurement of machine throughput. The EZ-SmartTower enables in-depth bottleneck identification, so machine shops can minimize downtime, maximize machine utilization, and optimize processes.

“In today’s business climate, maximizing shop efficiency is essential. The EZ-SmartTower will allow manufacturers to harness the power of machine data and streamline their ROI analysis,” said Michael Ricketts, Product Manager – Automation at Lyndex-Nikken. “This allows manufacturers to optimize their operations, drive profitability, and be more competitive.”

COMMENTS