Marposs has announced that it will unveil a range of new solutions for quality control, tool diagnostics, and machine tool integration at EMO 2025. The innovations span multiple manufacturing processes, including grinding, turning, and electric powertrain applications.

With an emphasis on enhancing measurement precision and process reliability, Marposs aims to demonstrate how its technologies are driving advancements in industrial control. Visitors can explore these innovations at Hall 5, Stand D13 during the exhibition.

The VTS (Visual Tool Setter) is a non-contact optical system designed to inspect and measure cutting tools using CCD sensors and shadow projection. At EMO 2025, Marposs will introduce a significant enhancement to the system: the new Surface Integrity Check software. This feature enables automatic detection of tool wear without requiring reference images, making it suitable even for tools that have not been previously inspected.

To support this function, VTS is now equipped with a six-LED light ring that eliminates reflections and unwanted shadows, ensuring consistent image quality and more reliable analysis across a wide range of tool types.

Integrated with the CNC, it enables automatic inspections during the machining cycle, transmitting tool wear status directly to the machine. The operator can view high-quality images directly from the machine control, avoiding machine stoppages and manual microscope inspections. This marks a significant step toward in-process metrology and smart automation.

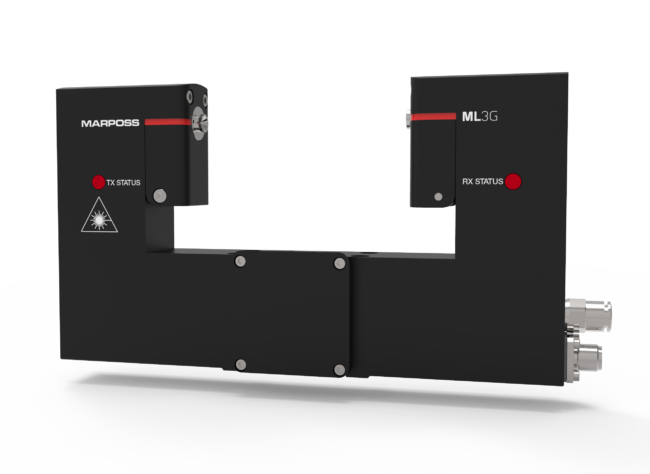

ML3G: Precision and Reliability in Laser Tool Measurement

Among the highlights at EMO 2025 is ML3G, a new non-contact tool measurement system based on laser technology. Developed for use with small, delicate, or coated tools, ML3G enables rapid and precise measurements directly at real operating speeds, helping to eliminate errors caused by runout and dynamic variations.

Building on Marposs’ experience in laser-based tool measurement, the ML3G introduces several key enhancements: a high-performance processor for faster data processing, redesigned shutters for improved sealing, an integrated air blower for tool cleaning, and a reinforced mechanical structure to ensure stability even in challenging industrial conditions. With four available lengths and three mounting configurations, the system offers flexibility to suit a wide range of machine tools.

Grinding: New Developments in Process Monitoring

For the grinding sector, Marposs will present three new technologies aimed at improving process monitoring, control, and data management.

- The OTX system is a compact solution for grinding wheel balancing and vibration control. It operates at high spindle speeds and uses ultrasonic sensors to detect and process vibration signals directly at the source, helping to maintain stability and surface quality during machining.

- The BLÚ system is a centralized digital platform for managing sensor data on machine tools. At EMO 2025, it will feature the new RECORDING function, which enables continuous tracking and storage of process data. Information collected by the sensors is stored in the BLÚ MASTER unit and can be exported for external analysis—supporting advanced diagnostics and potential integration with AI-based optimization tools.

Smart Factory: The New C-THRU4.0 Software Suite

At EMO 2025, Marposs will present C-THRU4.0, a modular, web-based software suite developed to support the digital transformation of manufacturing operations. The platform collects and analyzes production data in real time, enabling users to monitor key performance indicators, optimize tool usage, manage energy consumption, and improve overall equipment efficiency.

C-THRU4.0 is already in use in several industrial environments, where it integrates with machine tools and measurement systems to support data-driven decision-making and continuous improvement across the production line.

Featuring an intuitive graphical interface, C-THRU4.0 supports technical staff in detecting anomalies and choosing corrective actions, providing benchmarking across machines, lines, and shifts, and validating the effectiveness of interventions over time.

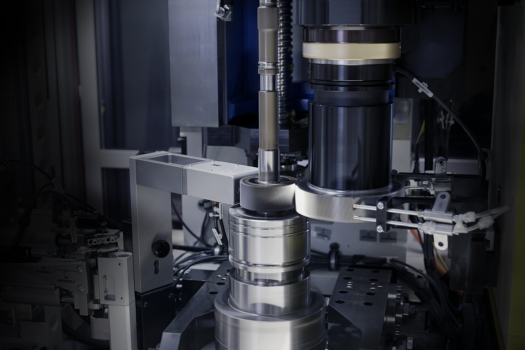

NVH G-EAR: Guaranteed Quietness in Electric Drivetrains

With the rise of electric and hybrid vehicles (EV/HEV), transmission noise has become a critical factor for comfort and perceived quality. The new version of the NVH G-EAR machine is Marposs’s answer to this challenge—a system capable of testing each individual gear before final assembly under real operating conditions (2,000 rpm, 25 Nm), using single flank rolling with a master gear.

The competitive advantage is clear: identifying potentially noisy gears before they enter production drastically reduces rework, scrap, and costs. During EMO, visitors will be able to explore the system’s full capabilities thanks to a large interactive display and the support of Marposs specialists on-site.

COMMENTS