Meusburger has highlighted its capabilities in providing high-precision solutions for electrical discharge machining (EDM), a critical process in the manufacture of high-quality injection moulds. As a leading standard parts supplier in the mould and die making industry, Meusburger offers a comprehensive range of products readily available from stock, designed to support both electrode production and sinker and wire EDM operations.

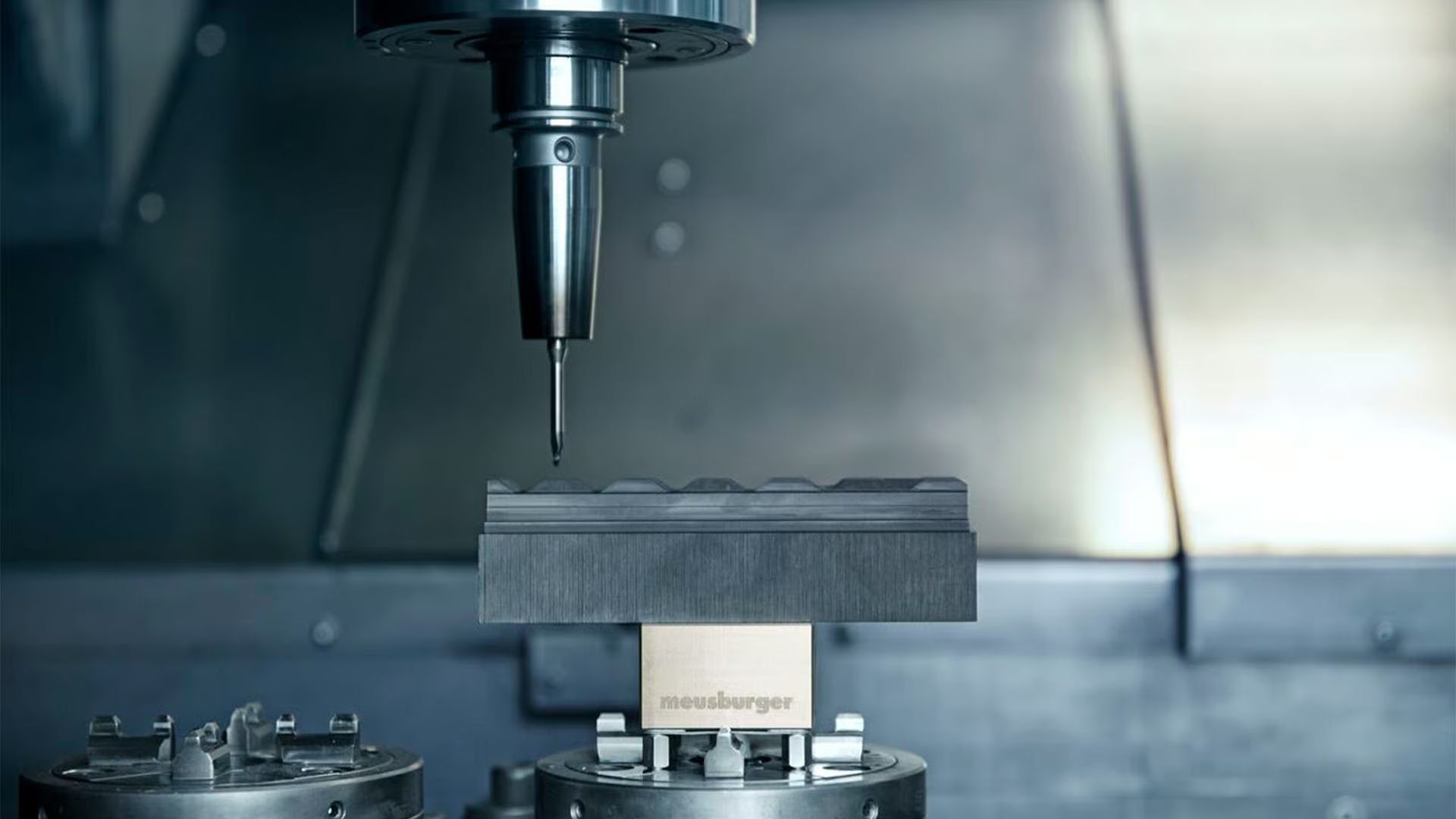

Fully equipped for precise electrode production

Precision production of electrodes is a key step in the manufacture of injection moulds and determines the quality of the final product. Meusburger offers a wide range of products for accurate and efficient machining, which includes special tool holders (steep taper and hollow shank taper systems) for secure and accurate tool retention, reliable milling cutters for machining electrodes, and high-quality electrode holders for secure fixing. Practical EDM accessories complete the range to ensure maximum precision and efficiency in electrode production.

Efficient sinker and wire EDM with the right components

For complex contours or fine details – Meusburger delivers the required components for efficient sinker and wire EDM.

- Sinker EDM: This manufacturing technology is specially optimised for hardened workpieces. High-quality electrode holder systems, clamping elements and materials are crucial for stable positioning and optimal transmission of the electrical conductivity.

- Wire EDM: The right clamping equipment is essential for machining workpieces with complex shapes. Meusburger’s clamping systems are optimally tailored to the requirements of wire EDM. They securely hold the workpiece in place, reduce vibrations and help to improve machining quality.

High-quality materials for every requirement

Meusburger offers an extensive range of EDM copper and EDM graphite in various formats and material qualities, guaranteed to be highly precise and available immediately from stock:

- EDM graphite (e.g. Q40, Q60, Q70) is characterised by the surface quality that can be achieved, depending on the pore size. Especially fine-grained types with low porosity enable very fine results (better than 16 VDI/0.63 Ra). Despite its lower thermal conductivity compared to copper, graphite remains dimensionally stable even under thermal stress.

- EDM copper is the first choice when it comes to the highest surface quality requirements, due to its non-porous and uniform structure. It offers excellent electrical conductivity and high thermal conductivity, which quickly dissipates heat and protects both the tool and the workpiece.

- Tungsten copper (WCu) is a compound material that combines the hardness and wear resistance of tungsten with the high conductivity of copper. It is used as a high-performance electrode material when conventional copper alloys reach their limits.

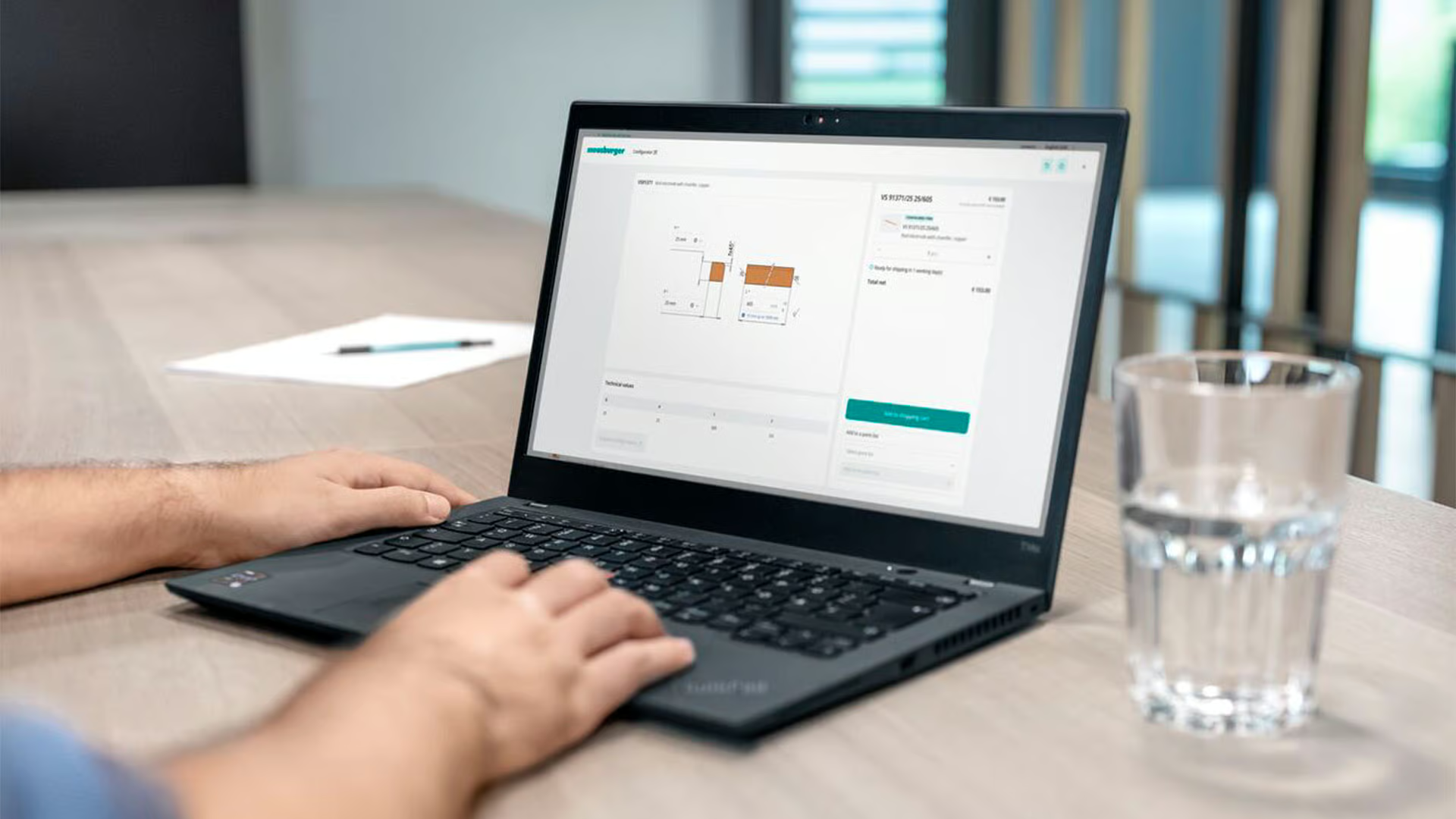

Easy configuration of accessories

To optimise the ordering process, Meusburger offers an intuitive configurator for EDM accessories in its portal. Customers can quickly and efficiently assemble EDM copper, graphite electrodes, rod electrodes and graphite cuts according to their requirements. Operation is simple and allows direct input into the dimensional drawing. A clear overview of all technical specifications, immediate price and availability information, and direct access to CAD data make the procurement of EDM components more efficient than ever before.

COMMENTS