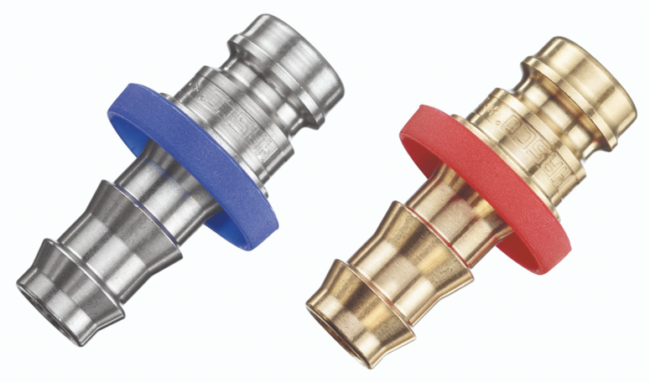

The new HASCO Push-Lok plug-in connectors Z83PL/…, made of brass and 1.4305 stainless steel, guarantee reliable and long-lasting cooling applications. The stainless steel model (VA) is ideal for use in medical and clean-room applications, in which the highest hygiene standards have to be adhered to.

The patented Push-Lok system makes it even easier and faster to equip moulding tools with the relevant equipment. The coloured marking of the plug-in connector guarantees the immediate recognition of the inflows and outflows on the moulding tool. Assembly is particularly easy and inexpensive because no additional components such as hose clips are needed. Repairs can be carried out quickly and directly on the workbench, thus minimising stoppage times. The system is optimally coordinated to all HASCO cooling elements and thus ensures seamless integration into existing systems.

The HASCO Push Lok system stands for reliability, efficiency and simple handling. It underlines the company’s commitment to always offer its customers the best and most innovative solutions in the field of cooling technology.

COMMENTS