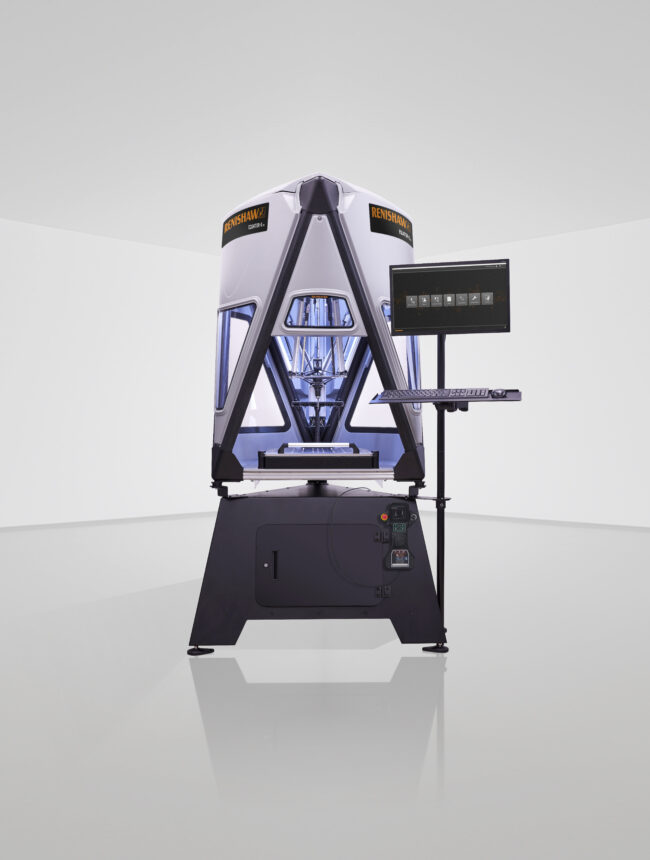

The new system expands the Equator™ range of versatile gauges for shop floor process control, high-speed measurement and quality assurance.

Renishaw recently announced the launch of its latest pioneering solution for shop floor process control, the Equator–X 500 dual-method system. This product offers manufacturers worldwide to select the optimum inspection method, Absolute or Compare, for their process challenge, effectively deploying two systems in one.

The Equator–X system is specifically engineered for dynamic shop floor environments where product variety and frequent design changes require measurement systems that are able to provide speed, flexibility and ease of use to keep pace with machining capabilities. Its key advantages include enhanced throughput and inspection capacity, fully traceable in-process part verification on the shop floor, continuous process validation, and the flexibility to select the optimal measurement method for each application with a single device

Speed and flexibility

The optional Absolute or Compare measurement modes address the demands of fast-paced manufacturing environments with different requirements.

In Absolute mode, the Equator–X system measures parts at scanning speeds of up to 250 mm/s, greatly enhancing the inspection capacity and throughput dealing with manufacturers of small to medium batch sizes and high part variety. This mode is particularly valuable for first-off verification next to the machine or even at-line 100% inspection.

In Compare mode, the Equator–X system delivers an ultra-high scanning speed of up to 500 mm/s and is ideal for inspecting large batches of the same component when cycle time is a priority. It also provides a high-speed measurement option where varying thermal environments present a challenge

Innovative technology and versatile software platform

The Equator–X 500 gauge is a hexapod structure with independent drive and metrology frames. High-speed motion is achieved without compromising metrology thanks to design features such as carbon fibre metrology struts, linear motor drives and the industry standard SP25M scanning probe.

The system can be deployed as a standalone shop floor device or integrated within a fully automated cell, offering unrivalled flexibility to adapt to evolving demands and variable shop floor conditions.

The standard software platform for the new Equator–X 500 system combines an intuitive and feature rich operator interface coupled with Renishaw’s latest MODUS™ IM metrology software applications. This comprehensive suite of software tools offers outstanding convenience and robust performance for programming, reporting and operation, simplifying complex tasks and enhancing user experience.

COMMENTS