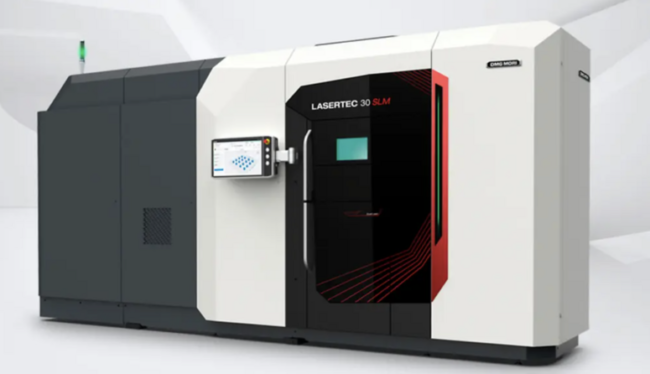

DMG MORI lays a fresh foundation for Additive Manufacturing with the introduction of the LASERTEC 30 SLM 3rd Gen at their Open House in Bielefeld.

This new platform for additive manufacturing has been designed from the ground up using all the additive and machine tool design know-how within DMG MORI. With its new quad laser full overlap working area, and a build volume of 325 x 325 x 400 mm, the center of market demand is targeted. The LASERTEC 30 SLM 3rd Gen is the new benchmark for robustness and repeatability.

The LASERTEC 30 SLM 3rd Gen builds on strengths from previous versions and accommodates customer requirements in an ever-changing market for additive manufacturing. The most obvious feature when looking under the covers is that the LASERTEC 30 SLM 3rd Gen basic structure uses castings. The same material and design principles that are used on the majority of DMG MORI milling and turning machines. Using a casting is standard practice for DMG MORI, but is new to additive manufacturing. It is a material that guarantees the best rigidity and predictability for manufacturing.

Unlike machine tools, there are no dynamic forces from the movement of the axes on a LASERTEC 30 SLM 3rd Gen. However, temperature changes that cause thermal expansion within the machine are inevitable. DMG MORI has years of experience in minimizing the effect of and compensating for temperature changes within its products. Great care has been taken to ensure that the process chamber is an isolated unit within the machine. Therefore, the Floating Process Chamber is free to expand in all directions during temperature variations. In contrast, the optics are mounted on the rigid casting Gantry Frame. The distance in Z between the optics and powder bed is kept constant by calibrating the recoater to a reference surface. In addition the Z-axis is actively compensated for any displacement. Therefore, problems related to the distance between the optics, the top surface of the powder bed and associated problems with the recoating layer can be eliminated.

To reduce time between build jobs and to increase flexibility, the DMG MORI rePLUG units have been an important competitive advantage on previous SLM products. The rePLUG is a self-contained automated powder material processing unit that can be exchanged with other rePLUG units. Existing customers with qualified processes, which are often found in the aerospace and medical industries, appreciate and rely on the rePLUG system to ensure top quality powder is continually in use. The excess powder from the working area is sieved, stored and prepared for re-use, all under an inert gas atmosphere within a closed loop. This not only minimizes oxidization or any moisture build-up, but also reduces potential operator exposure to the powder. An important safety consideration. For other customers the rePLUG makes changing between different materials much easier. Other related components inside the machine itself can be as easily cleaned, making the LASERTEC 30 SLM 3rd Gen the quickest machine to change between materials on the market. This greatly widens the range of applications that a single machine can be used for.

For the first time on a DMG MORI LASERTEC SLM, it is possible to exchange the build container quickly. This further increases machine efficiency since it is no longer necessary to wait for the build job to cool down. Covers for the build container and the working area are stored inside the working area during operation. These are used to close off the build container upon removal and to ensure that the inert gas atmosphere inside the machine is preserved. The next build job can be quickly started without a renewed inert gas flooding.

Disruption during manufacturing is further minimized by camera monitoring of the surface of the powder bed. After each layer, the surface is scanned for anomalies before the re-coater moves. If there is a protrusion that is not detected in time, then the bi-directional re-coater is equipped with a collision protection mechanism to shorten any subsequent downtime. Upon making contact with a protrusion sticking up from the bed, the re-coater immediately detaches from the drive system, thus avoiding further damage.

The newly designed inert gas flow over the powder bed ensures a consistent laminar flow during operation. The secondary gas flow below the protective glass aims to avoid any residue build up on the protective glass. The wind tunnel like design ensures unprecedented gas flow performance. The protection glass itself is under constant observation by a secondary camera system that gives a warning if there is a problem. Additional lighting is provided in the area of the protective glass to support the operator when checking and cleaning the protective glass between build jobs.

DMG MORI places a lot of emphasis on the usability and ergonomics of the machine. Reducing the operator contact with the powder is a primary consideration. Another key area where the LASERTEC 30 SLM 3rd Gen excels is with the CELOS X operating environment. CELOS X guides the operator through all the steps required to get a job running. For example, it prompts the operator to clean the safety glass and shows how it is done. It also walks the operator through the powder refilling process or how daily checks and maintenance are to be performed. CELOS X guidance is important for the adoption of safe and efficient operating procedures on the shopfloor.

COMMENTS