Seco has announced the launch of the .38 Finishing Face Mill system, a new range of cutters engineered to deliver high-precision surface finishing across diverse manufacturing applications. Built with ready-to-use simplicity, hybrid flexibility, and ultimate adjustability, the system is designed to meet the full spectrum of finishing needs—efficiently and flawlessly.

Versatility Through Cutter Variants and Insert Options

The .38 Finishing Face Mill / SNFX1204 system introduces three distinct cutter variants—fixed pocket, hybrid, and adjustable—each offering a different balance of control and performance. Whether a manufacturer’s priority is achieving highly consistent surface finishes or minimizing setup effort, the system provides a practical and flexible solution.

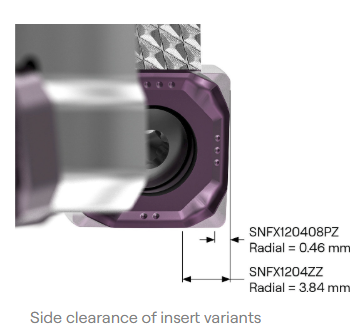

To further extend its versatility, the system incorporates two insert types to handle varied demands. One insert comes with an 88° lead angle, making it ideal for near-wall machining, while the other features a 27° lead angle, optimized for high-feed, open-surface work. This combination ensures manufacturers can address a wide range of finishing challenges while keeping operations simple and cost-effective.

With this new launch, Seco reinforces its commitment to developing advanced tooling solutions that simplify precision machining, increase flexibility, and help manufacturers achieve superior results in finishing operations.

The Face Finishing .38 / SNFX1204 system is all about giving you flexibility and precision in your finishing operations. It comes in three cutter variants—fixed pocket for easy plug-and-play use, hybrid for a balance of handling and surface finish, and adjustable for top-tier performance and tool life.

Each cutter works with two insert types: one with an 88° lead angle for near-wall machining, and another with a 27° lead angle for high-feed, open-surface work. With just one system and two insert styles, you can tackle a wide range of finishing challenges while keeping things simple, efficient, and cost-effective.

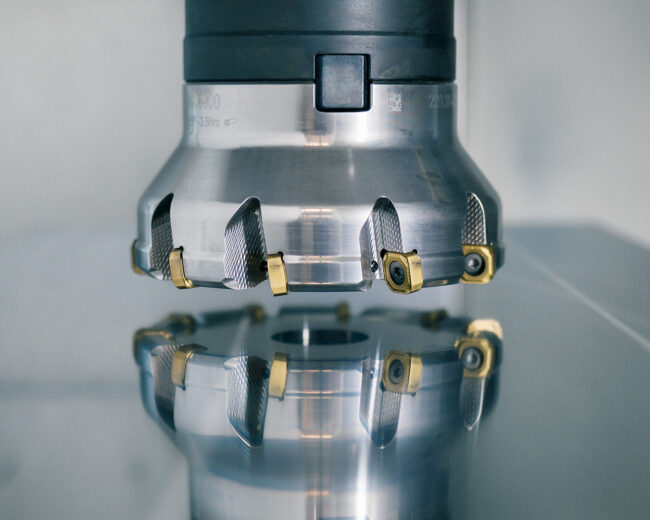

The fixed pocket cutter: plug-and-play precision

The fixed pocket cutter is designed for effortless handling and setup-free operations. With a tilted screw design that ensures perfect insert self-centering, this cutter delivers excellent run-out accuracy (4–15 µm) and is ideal for users who want high surface finish quality without the hassle of adjustments—making it a cost-efficient milling solution that reduces setup time, operator error, and the need for training.

Setting up cutters and adjusting inserts to the correct height can be time-consuming, error-prone, and require skilled labor—especially in high-precision finishing. Setting up cutters and adjusting inserts to the correct height can be time-consuming, error-prone, and require skilled labor—especially in high-precision finishing.

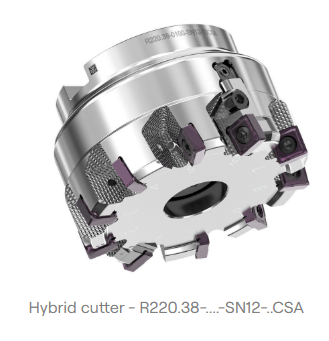

The hybrid cutter: balanced performance meets flexibility

The hybrid cutter combines the best of both worlds: fixed pocket inserts and cassette pockets that can be adjusted if needed. It offers a balanced solution for users who need improved surface finish and reduced burr formation without the complexity of full adjustability. The cassette inserts create the smooth surface finish, while the fixed inserts handle the material removal—resulting in lower tool pressure and excellent chip control. This makes it perfect for applications where surface quality and ease of use must co-exist.

Achieving a high-quality finish while minimizing burrs and tool pressure—without complicating the setup process. The hybrid cutter delivers a smart balance of performance and simplicity. It reduces burrs and improves finish while keeping handling straightforward.

The adjustable cutter: ultimate control for demanding finishes

For the most demanding finishing applications, the adjustable cutter offers unmatched precision and tool life. Each pocket can be fine-tuned to achieve run-out as low as 0–2 µm, enabling mirror-like surface finishes even at high feed rates. This cutter is ideal for experienced users who need full control over every detail of the milling process and are willing to invest in setup time for superior results.

When surface finishing requirements are extreme, even minor setup errors can lead to costly rework or scrap. The adjustable cutter gives you full control over run-out and insert positioning, ensuring the highest possible surface quality and tool longevity.

Tobias Jakobi, Product Manager Face Milling at Seco, said, “With the .38 Finishing Face Mill system, we’ve focused on making high-performance finishing both easy and dependable. Ease of handling is essential in finishing operations, and this solution gives users the flexibility to meet varying demands—often with just one system where two might have been needed before.”

The .38 Finishing Face Mill system will be available globally starting in September 2025.

COMMENTS