SECO Tools has recently launched the MK1501, a robust and versatile milling insert grade designed specifically for cast iron machining. Engineered to deliver consistent performance in both wet and dry conditions, the MK1501 offers manufacturers greater flexibility across applications.

The grade is characterized by predictable wear, high heat resistance, and visual edge detection, enabling higher productivity, reduced costs, and reliable machining results. Whether coolant is used for chip evacuation and heat management or not, the MK1501 ensures stable and efficient performance, making it a trusted solution for diverse cast iron milling challenges.

Built for Lasting Performance

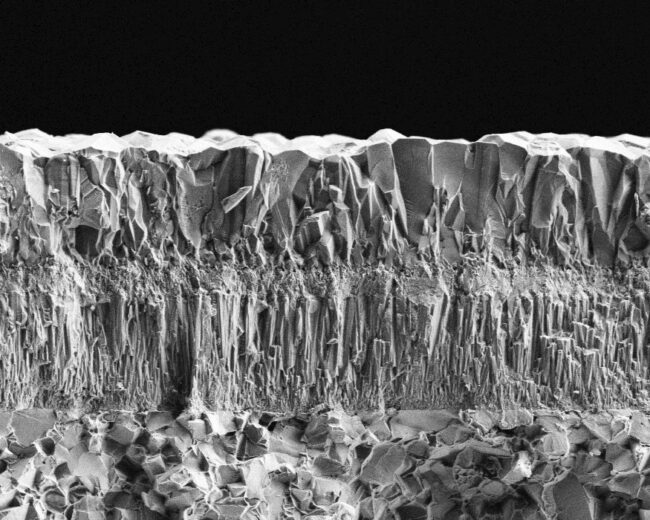

The chrome-colored MK1501 grade is the newest generation of Duratomic® inserts with a CVD coating. They are built to last longer and resist wear. Plus, the cutting edges change from chrome color to black when it is worn out, so you can easily tell when it’s time to replace them. This means you’ll get the most out of each insert, boosting productivity and cutting down on tooling costs.

Many customers struggle with tools wearing out too quickly or unevenly when milling cast iron, resulting in wasted inserts and an unreliable process. The MK1501 grade solves this with advanced post-treatment processes that make it tougher and less prone to sudden breakages. At the same time, its used edge detection feature ensures every insert is fully utilized before replacement, reducing waste and boosting productivity.

Built for Cast Iron

The new post-treatment processes of the MK1501 grade make it tougher, meaning the wear is predictable and increases the opportunities for unmanned production. Plus, with the MK1501 grade, you get more precise cutting data recommendations for cast iron materials, especially when machining grey cast iron and ductile cast iron.

To stay competitive, manufacturers need to boost productivity and cut costs, but unpredictable tool performance and sudden insert failures often cause downtime and added expenses. The MK1501 grade addresses these challenges with high heat and wear resistance, enabling higher cutting speeds, shorter cycle times, and reliable cast iron milling. Its predictable wear behavior ensures consistent performance, minimizing disruptions and supporting greater efficiency.

COMMENTS