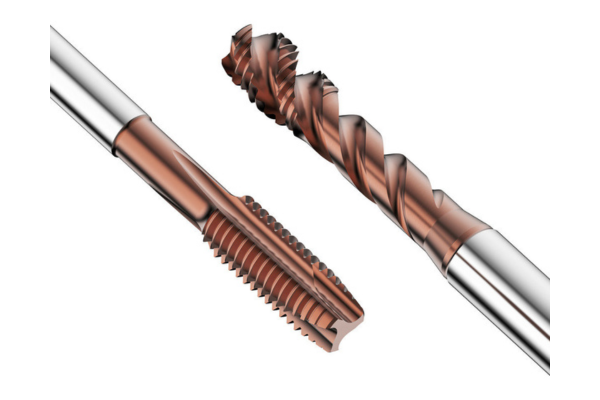

Seco T35 Taps enhance tool life, reduce part costs, and improve production quality in high-volume runs with tooling tailored to specific materials. For optimal results, use T35-P for alloyed steels, T35-K for cast iron, T35-H for other tough, abrasive materials, and T35-N for aluminum. The TiAlSiN coating on T35-P, T35-K, and T35-H ensures excellent wear resistance in demanding conditions. Meanwhile, the highly polished, smooth T35-N design improves chip evacuation in aluminum machining.

Optimize Tapping of Alloyed Steels

Seco T35-P taps deliver enhanced performance in alloyed steels, thanks to their optimized geometry and specialized TiAlSiN coating. Applied using HiPIMS technology, the TiAlSiN coating offers outstanding smoothness, high hardness, and excellent resistance to cracking. The challenge is to increase tool life and reliability in alloyed steels with Rm 800–1200 MPa, and the Seco solution lies in T35-P taps made of HSSE-PM, which use a special geometry and TiAlSiN coating to minimize tool wear with alloyed steels.

Increase tool life & part quality in Cast Iron

Extend tool life and eliminate miscut threads with the special geometry of Seco T35-K taps, while a high-performance HiPIMS-applied TiAlSiN coating further enhances tool life and part quality. The challenge is to increase tool life and reliability in short-chip cast materials such as abrasive cast iron, and the Seco solution is T35-K taps made of HSSE-PM, which use a special geometry and a TiAlSiN coating to minimize tool wear with abrasive cast iron.

Another challenge is how to avoid miscut threads during tapping operations, and the Seco solution is the T35-K taps, which use a special geometry to eliminate miscut threads when tapping abrasive cast iron.

Tap Aluminum with chip control

Large, polished flutes and a specialized geometry give Seco T35-N taps excellent chip formation and evacuation in aluminum, helping eliminate long, stringy chips and improving part quality, process security, and tool life. The challenge is to increase tapping reliability and thread quality in aluminum parts, and the Seco solution is T35-N taps that incorporate large, smooth flutes for optimal chip formation and evacuation in soft aluminum parts.

Easily tap tough, abrasive materials and keep chips under control

With Seco T35-H threading taps, which excel in challenging materials. Their HSSE-PM material and TiAlSiN coating provide strong wear resistance in hard steels, cast irons, and cast aluminums. This flexibility allows the use of a single tool to handle materials with hardness ranging from 30 to 45 HRC. The challenge is to extend tap life in tough and abrasive materials, and the Seco solution is long tool life achieved through the HSSE-PM material and TiAlSiN coating of the T35-H taps. Another challenge is to minimize tool inventory, and the solution is the ability to tap hard steels, cast irons, and cast aluminums with a single T35-H tap.

Long, stringy chips pose a risk to your process and your operators. Seco T35-H threading taps incorporate a 15-degree helix angle that breaks tough materials into small, manageable chips, while relatively large tool flutes ensure efficient evacuation. The challenge is to control the generation of bird-nest chips when tapping blind holes in tough and abrasive materials, and the Seco solution lies in the helix angle that enables clean chip breakage. Another challenge is to effectively evacuate chips when using taps on a turning machine for blind holes, and the solution is the T35-H tap’s larger flutes and optional internal coolant, which ensure optimum chip evacuation.

COMMENTS