Sustainability has moved beyond a trend to become a strategic necessity across sectors, driven by environmental concerns, policy changes, and consumer awareness. In this evolving landscape, mould manufacturing must adapt to reduce its environmental footprint and promote resource efficiency without compromising quality and performance. This article aims to explore how the mould manufacturing industry can move toward greener practices, highlighting its current challenges, opportunities, and the innovative strategies shaping a more sustainable future.

Mould manufacturing plays a crucial role in the global manufacturing ecosystem, serving as the foundation for producing components in diverse industries such as automotive, consumer goods, packaging, electronics, and healthcare. Traditionally known for its precision and durability, the mould manufacturing sector is also resource-intensive, involving significant use of metals, energy, and machining processes. With global industries embracing sustainability as a core business imperative, the spotlight is now on mould makers to align with environmentally responsible practices.

Environmental Impact of Traditional Mould Manufacturing

Traditional mould manufacturing processes are inherently energy-intensive, particularly during the machining and heat treatment phases. High-precision machining requires significant electricity, especially when operating large CNC machines over long cycles. Additionally, material wastage remains a persistent concern, with a substantial portion of high-grade tool steel often ending up as scrap, especially in subtractive manufacturing environments. Recycling efforts, though present, are often inefficient or inconsistent across facilities. The environmental burden is further compounded by the use of hazardous coolants, lubricants, and cleaning agents, which can contaminate water sources and pose risks to workers’ health. Moreover, the heat treatment process emits greenhouse gases and contributes to air pollution, while transportation of heavy moulds across global supply chains results in added carbon emissions. These factors underline the urgent need for the mould manufacturing industry to reassess and revamp its traditional operations for a more sustainable approach.

Drivers of Sustainability in Mould Making

Several powerful forces are driving the shift toward sustainability in mould making. Foremost among them is the global push for net-zero emissions, which has led governments and organisations worldwide to adopt stricter environmental goals. Regulatory pressures—such as mandatory energy audits, carbon footprint disclosures, and waste management norms—are compelling mould manufacturers to align with sustainable standards. Simultaneously, there is increasing customer demand for eco-conscious partners in the supply chain, especially from multinational corporations with their own sustainability targets. Beyond compliance and demand, sustainability also presents a compelling business case: energy and material efficiency can significantly reduce operational costs in the long run. Moreover, sustainability is becoming a part of corporate social responsibility, enhancing brand image and positioning mould makers as progressive and responsible players in the market.

Challenges in Implementing Sustainability

While the path toward sustainability is promising, it comes with its own set of challenges. One major hurdle is the cost of transitioning to green technologies, which can be high, especially for small and midsized tool rooms. There is also the limited availability of eco-friendly materials in certain regions, making adoption inconsistent. Another challenge lies in the training and mindset shift required among the workforce to embrace new practices and technologies. Finally, initial investments in process redesign or automation can deter companies from making immediate changes despite long-term benefits.

The Role of Digitalisation and Industry 4.0

Digitalisation is a powerful enabler of sustainability in mould manufacturing. Smart sensors and IoT systems allow real-time monitoring of energy and resource usage, helping managers identify inefficiencies. Predictive maintenance technologies extend the life of expensive moulds by identifying wear and potential failure points early. Digital twins allow for advanced simulation and design optimisation before physical production, reducing resource usage. Moreover, integrating sustainability metrics into ERP systems ensures traceability and reporting, supporting regulatory compliance and continuous improvement.

Future Outlook

The future of sustainable mould manufacturing is set to be shaped by multiple transformative trends. Tool rooms are increasingly seeking sustainable certifications that validate their environmental performance and appeal to global clients. We can also expect greater collaboration across the value chain, with OEMs, material suppliers, and mould makers working together to set common sustainability goals. Governments are likely to introduce stricter policies and carbon-neutral mandates, pushing the industry toward cleaner operations. Finally, the expanding role of automation, artificial intelligence, and process innovation will continue to unlock new ways of manufacturing moulds with minimal environmental impact.

Strategies for Sustainable Mould Manufacturing

Eco-Friendly Design Practices: Sustainable mould making starts with smart design. By designing moulds for longevity and reusability, manufacturers can reduce the frequency of replacements and maintenance. Lightweight designs, when feasible, reduce material use without compromising structural integrity. Simulation tools enable engineers to optimise mould designs virtually, cutting down on physical prototypes and reducing energy and material waste.

Material Innovation: Using recyclable and eco-friendly tool steels helps minimise the environmental impact of raw material sourcing. Manufacturers are also exploring alternatives to conventional grades like P20, including composites and hybrid materials that offer better efficiency and lower carbon footprints. Furthermore, reusing scrap and recovered materials within internal operations can reduce dependency on virgin material inputs.

Energy-Efficient Machining and Processes: Modern CNC machines are increasingly designed for energy efficiency, offering better output per unit of electricity consumed. Techniques like dry machining or minimum quantity lubrication (MQL) significantly cut down the use of hazardous coolants. In parallel, some tool rooms are switching to renewable energy sources, such as solar or wind, to power their manufacturing units.

Additive Manufacturing (3D Printing): Additive manufacturing brings notable sustainability benefits by building mould components layer by layer, significantly reducing material wastage. It also enables the creation of conformal cooling channels, which enhance energy efficiency during the moulding process. Furthermore, 3D printing supports localised and on-demand production, cutting down on inventory requirements and transportation-related emissions.

Closed-Loop Systems & Waste Management: Implementing closedloop systems helps capture and recycle machining chips and scrap metal efficiently. Advanced coolant filtration and recovery systems reduce waste and limit chemical discharge. Similarly, optimised water management practices and environmentally friendly cleaning agents contribute to a more sustainable shop floor.

Conclusion

Sustainability is no longer optional in mould manufacturing—it is a critical factor for long-term competitiveness and compliance. From minimising waste and emissions to adopting green technologies and digital tools, the industry has multiple pathways to reduce its environmental footprint. However, this transformation requires a collective effort, involving not just manufacturers but also policymakers, suppliers, and end users. By balancing productivity with environmental responsibility, mould makers can position themselves as leaders in a greener, more resilient manufacturing future.

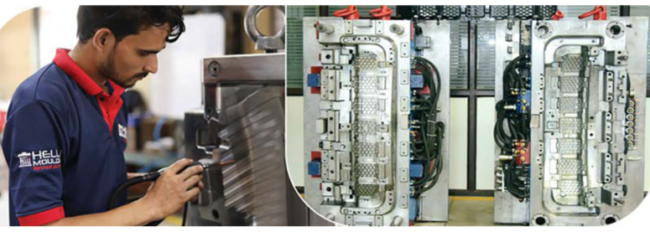

Article and Images Courtesy: Helli Moulds

This article was published in TAGMA Times

COMMENTS