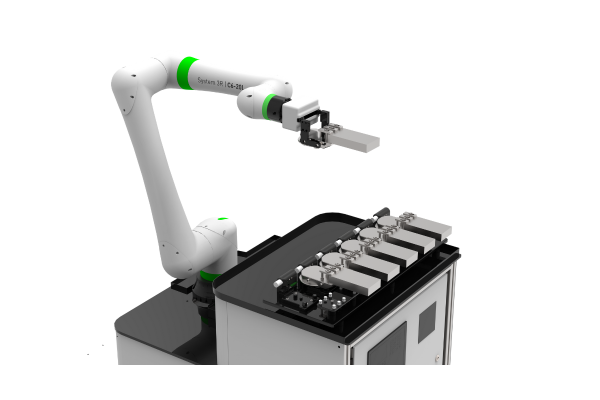

The newly developed C6-20L cobot solution from System 3R reflects the ongoing commitment to the “lights out factory” concept. Expanding the robot portfolio to include cobot technologies aligns with the growing industry shift towards greater automation, particularly as Autonomous Mobile Robots (AMRs) continue to gain prominence across manufacturing environments.

The C6-20L cobot solution stands out for its process-focused design, aimed at ensuring operational reliability for the customer. By integrating sensors, ID systems, and WSM software, the solution enables intelligent process control. Floor scanners further enhance this by allowing operators to safely interact with the cobot’s magazine—adding, removing, or repositioning parts as needed. Once the operator exits the magazine area, the system re-scans and automatically resumes operation, maintaining both safety and workflow continuity. Designed to operate in collaborative mode, the cobot ensures a consistently safe environment for the operator throughout the interaction.

All 3R robot types and cells, including the cobot, are compatible with the WorkShopManager (WSM) software system and integrated ID solutions.

The latest version, WSM 5.0—which will be showcased at EMO—introduces support for AMRs and is designed for seamless factory-level integration. With its user-friendly interface, WSM 5 simplifies the management of complex, multi-technology workflows. Operators can easily adjust priorities using a drag-and-drop feature directly on the automation control panel, offering maximum flexibility.

By minimizing human error and enabling real-time tracking of every workpiece, the automated system ensures consistent output and helps reduce overall downtime.

COMMENTS