Tungaloy Corporation recently announced the expansion of its DoFeedTri series, introducing a new grade optimized for stainless steel machining, enhanced low cutting force chipbreakers, and an extended range of cutter bodies for improved versatility and performance.

Challenges and Trends

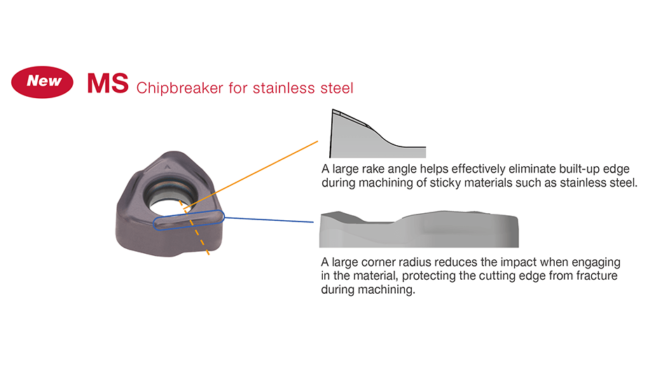

In general machining, stainless steel remains one of the most challenging materials to process. In particular, when machining from solid blocks, the cutting tools are subjected to high loads, leading to issues such as rapid wear and shortened tool life. The conventional DoFeedTri series had limited options in terms of grades and chipbreaker types, which made it difficult to meet the growing demand for diversified machining conditions, higher efficiency, and extended tool life. Against this backdrop, further performance enhancements and expanded adaptability are being called for to address these Challenges and Market Conditions.

Product Overview

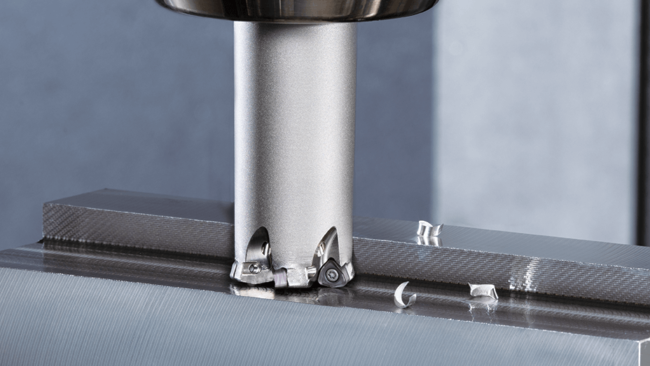

DoFeedTri, featuring a high-rigidity design and double-sided insert with six cutting edges, is a high-feed cutter ideal for high-efficiency roughing and ramping operations. Its excellent chip evacuation and durability significantly enhance machining efficiency and tool life.

Benefits and Features

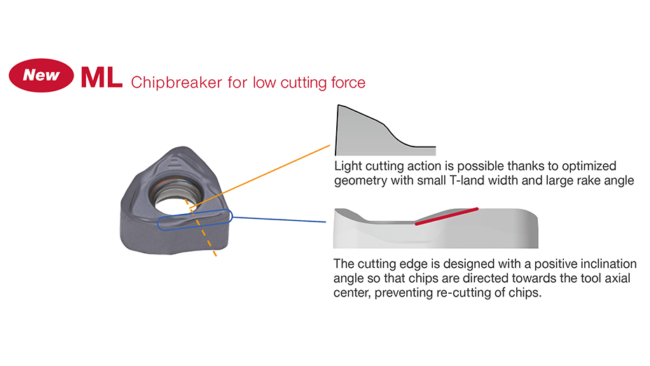

Grades and chipbreakers optimized for stainless steel machining, and low cutting force chipbreakers

・The newly expanded AH130 grade delivers excellent wear and fracture resistance in stainless steel applications

・Low cutting forceand chipbreakers reduce cutting forces

・Reverse-positive land geometry enhances cutting edge strength and minimizes insert chipping risk

Insert design combining high machining stability and cost efficiency

・Double-sided, 6-corner inserts maximize the number of usable edges per insert, improving cost performance

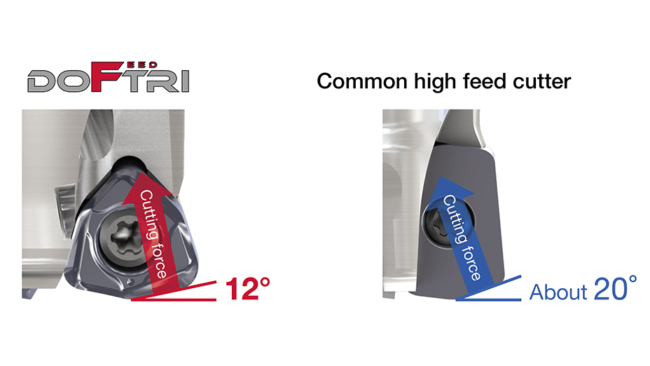

・The 12° entry angle directs cutting forces toward the tool axis, reducing vibration during machining

・Wide inner cutting edge design enables a 3-degree ramping angle with ø16 size, supporting inclined cutting operations

Expanded cutter body lineup to meet diverse machining requirements

・Wider range of diameters available for under-shank types, modular cutters, and bore-type cutters

・Flexible compatibility with various machine tools and machining conditions

・Greater freedom in tool selection facilitates optimization in production environments

COMMENTS