WALTER has introduced a new system called “Automated Tool Production (ATP),” which automates the production of cylindrical precision tools. This system is designed to connect WALTER’s grinding, eroding, and measuring machines, as well as machines from other companies involved in the production process.

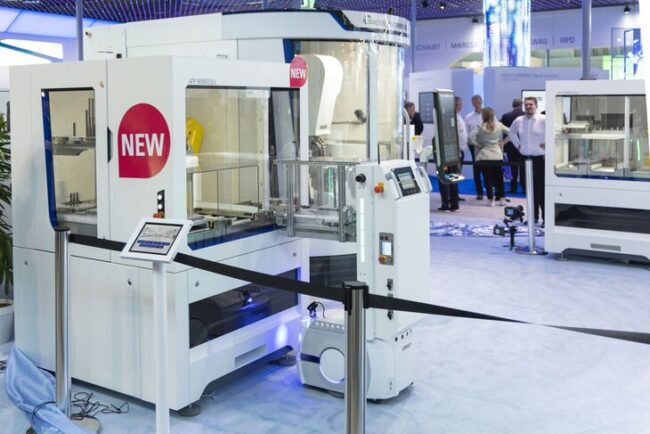

The ATP system requires no additional floor space, can be integrated into existing system layouts and is also suitable as an interface for machines from other manufacturers. It consists of at least one robot cell (ATP ROBOCELL) accessible from the front for automatic loading and unloading of the machines and at least one autonomous, mobile transport robot (ATP Mobile Robot) for transporting the tool pallets and individual parts between the storage and processing stations. This also includes a standardised communication model between the machines and the ATP AMR transport robot as well as a control system for higher-level data and process control.

Advantages of the ATP system

- One system for all grinding, measuring and eroding machines from WALTER

- Can be retrofitted without changes to the system layout

- Front-accessible ATP ROBOCELL with 3 access gates and buffer stations for production without downtimes

- Separate removal station for in-process exchange of individual parts between measuring and processing machine

Advantages of the ATP ROBOCELL

- One ATP ROBOCELL for WALTER measuring and grinding machines

- Can be retrofitted

- No changes to the layout of the production system necessary

- No additional floor space required

- No downtime when changing tools and pallets

- Buffer spaces for loading and unloading

- Upgrade options such as collet change, individual tool cleaning options

- and much more…

Technical Data

- Min. tool diameter: 3 mm

- Max. tool diameter: 32 mm

- Max. tool length: 250 mm

- Max. tool weight: 2,5 kg

- Max. total weight carrier: 40 kg

- Max. tool capacity: ∞

COMMENTS