In modern manufacturing, sheet metal parts play a critical role in various industries, including automotive, aerospace, and consumer electronics. However, producing defect-free sheet metal components remains a challenge. Common defects, such as wrinkles, cracks, thinning, and springback, often affect product quality and manufacturing efficiency. These defects can result in costly reworks, production delays, and material waste, which further strain manufacturing operations. In this context, simulation technology has become a crucial tool for predicting and preventing defects in sheet metal parts, helping manufacturers improve product quality while reducing production costs and lead times.

By – Shashank Patake

Evolution of Simulation Technology in the Sheet Metal Industry

Simulation technology has significantly evolved over the years, transforming from rudimentary models to sophisticated systems that can accurately predict real-world outcomes. Initially, manufacturers relied on trial-and-error methods to perfect their designs and tooling, leading to substantial time and material wastage. However, with the advent of finite element analysis (FEA) and advanced simulation software, manufacturers can now predict defects in sheet metal forming processes before the physical production phase. These tools allow engineers to simulate various forming conditions, test different material properties, and optimize tooling designs, ensuring that potential issues are identified and resolved early in the design process. Today, simulation is an integral part of modern manufacturing, providing invaluable insights into material behaviour and forming dynamics.

Types of Defects in Sheet Metal Forming

Several types of defects can occur during the sheet metal forming process. Major defects include wrinkling, tearing, and springback. Wrinkling typically occurs when compressive forces act on the sheet, causing localized buckling or waves. Tearing, on the other hand, results from excessive tensile forces that cause the material to fracture. Springback is a geometric defect where the material attempts to return to its original shape after the forming process, leading to dimensional inaccuracies.

Other common defects include thinning, where material thickness is reduced beyond acceptable limits, and galling, where material adhesion occurs between the sheet and the tooling. Each defect has a specific root cause, often related to improper material selection, incorrect process parameters, or suboptimal tooling design. For instance, wrinkling is commonly caused by excessive compressive stress, while tearing can result from material brittleness or overstretching during forming.

Predicting Defects Using Simulation

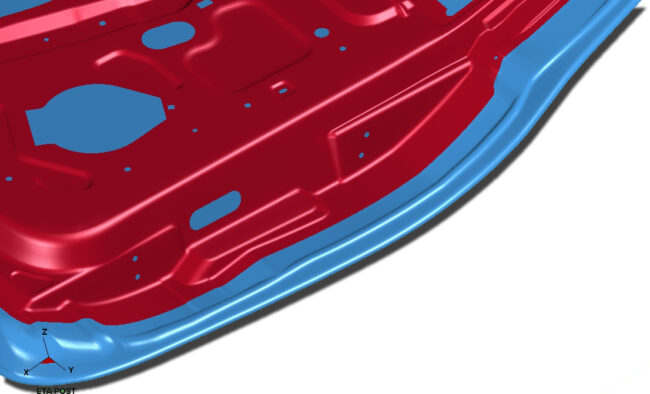

Simulation technology enables engineers to predict potential defects by modelling material behaviour under various forming conditions. Using finite element analysis (FEA), simulation software creates virtual representations of the sheet metal forming process, allowing engineers to study how materials deform, flow, and react to different forces. These models take into account material properties such as yield strength, strain rate, and hardening behaviour, enabling accurate predictions of defects like wrinkling, tearing, and thinning.

By simulating different process parameters—such as punch speed, friction conditions, and blank holder forces—engineers can observe how variations in these factors impact the likelihood of defects occurring. This predictive capability is invaluable in the early stages of product development, allowing manufacturers to test multiple scenarios and identify the most efficient and defect-free manufacturing setup.

Preventing Defects through Simulation

One of the key advantages of simulation is its ability to prevent defects by optimizing design and tooling based on simulation results. By adjusting material properties, refining tooling design, and fine-tuning process parameters, engineers can minimize the likelihood of defects. For instance, simulation can help identify the optimal blank holder force to prevent wrinkling, or the correct material thickness to avoid tearing. Additionally, simulation provides insights into how different materials react to specific forming conditions, enabling engineers to select the most suitable material for the intended application.

Accurate simulation also guides the design of dies to avoid defects. Engineers can test die configurations and make adjustments based on simulation results, ensuring that the final tooling design produces high-quality parts. For example, if a simulation predicts excessive springback, the die can be modified to account for this deformation, resulting in a part that meets the required dimensional specifications. The ability to make informed design decisions based on simulation data greatly reduces the need for physical prototypes, saving both time and resources.

Challenges in Simulation Accuracy

While simulation is a powerful tool, it is not without its challenges. One of the primary limitations of simulation tools is the accuracy of the material models used. Real-world materials often exhibit complex behaviour that is difficult to capture in a simulation. For example, anisotropic material properties—where material behaviour varies in different directions—can be challenging to model accurately. Additionally, forming processes often involve non-linearities, such as contact between the tool and sheet or material strain hardening, which can further complicate the simulation.

Another challenge is the accuracy of real-world conditions. In some cases, the actual forming process may deviate from the simulated conditions due to variations in material properties, temperature fluctuations, or equipment inconsistencies. To address these challenges, manufacturers must use high-fidelity material models and continuously update their simulation parameters based on real-world data. Additionally, advances in machine learning and artificial intelligence are being integrated into simulation tools, allowing for more accurate predictions and real-time adjustments to the forming process.

Conclusion

The integration of simulation into the sheet metal forming process has revolutionized how manufacturers approach defect prediction and prevention. By simulating material behaviour, optimizing tooling design, and adjusting process parameters, manufacturers can identify and mitigate potential defects early in the development cycle. While challenges remain in achieving perfect simulation accuracy, ongoing advancements in simulation technology continue to enhance the predictive capabilities of these tools. Ultimately, the ability to predict and prevent defects through simulation leads to higher-quality products, reduced material waste, and more efficient manufacturing processes. As simulation technology continues to evolve, it will remain an essential tool for ensuring defect-free sheet metal parts in modern manufacturing.

About The Author:

Shashank Patake is the Director of Sales and Partner Engagement at Engineering Technology Associates, Inc. He excels in business development, GTM strategy, account and territory development. Shashank’s expertise spans CAD/ECAD, CAE and EDA industries, and he is known for effective management and continuous improvement.

COMMENTS