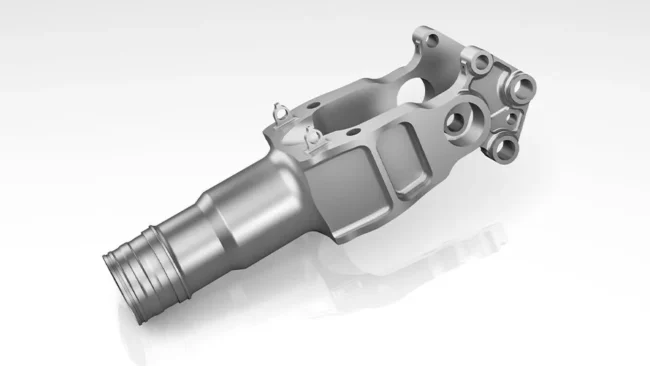

The piston within the main landing gear cylinder plays a crucial role in absorbing impact forces during landing and facilitates both the extension and retraction of the landing gear. As a key component of the landing gear system, the piston is attached to the cylinder and is responsible for cushioning the loads encountered during operation. The number and dimensions of these pistons can vary depending on the aircraft type, but all must adhere to stringent safety standards, which limits the selection to only a few suitable materials

These are mainly titanium alloys and high-alloy steels. But it is not only the materials that are demanding, the complexity of the components is also constantly increasing. In addition to the tool technology, the machining strategy is therefore particularly important. Contour milling, turning and holemaking are among the most important machining operations in this context.

Tooling solutions for components made of titanium alloys and high-alloy steels

- 3 cutting edges for maximum profitability

- 4 indexable insert types for flexible use

- Positive-locking indexable inserts for a secure hold in the insert seat

- Damping element flexibly mounted axially and radially

- Vibration-damping preset ex works

YOUR APPLICATION

Vibration-free turning of inner contours

OUR SOLUTION

Accure·tec® vibration-damped tool adaptor with WL25

BENEFITS FOR YOU

High flexibility as well as maximum surface quality and process reliability due to vibration-free machining.

- Universal application with all ISO material groups

- Wear-resistant high-performance grade WK40TF

- Plug & play solution: Xill·tec® MC230 Advance and Walter GPS

YOUR APPLICATION

Roughing, dynamic milling, finishing

OUR SOLUTION

Walter Prototyp Xill·tec® solid carbide milling cutter MC230 Advance

BENEFITS FOR YOU

High flexibility due to universal applicability. Long tool life and lower tool costs due to high-performance grade WK40TF.

- Internal coolant supply for cooling directly at the drill insert

- Highly positive geometry

YOUR APPLICATION

Drilling of connection holes

OUR SOLUTION

Walter Drion·tec® exchangeable tip drill D4140

BENEFITS FOR YOU

High productivity due to short drilling cycles and reliable drilling without vibration as a result of the positive locking of the drill insert.

- 4 cutting edges per indexable insert

- Stable, tangential insert clamping

YOUR APPLICATION

Shoulder milling, roughing

OUR SOLUTION

Walter BLAXX shoulder milling cutter F5141

BENEFITS FOR YOU

Highly reliable and cost-efficient tool with maximum stability.

COMMENTS