Siemens Digital Industries Software recently announced the latest updates to its Simcenter™ Testlab™ software, including new AI-assisted workflows that accelerate modal analysis processes by up to 7x while reducing the personnel needed to perform physical impact testing. The updates also bring automated data capture and processing, improving data quality and consistency across all testing phases—enabling engineers to test faster, smarter, and earlier than ever before.

Jean-Claude Ercolanelli, Senior Vice President, Simulation and Test Solutions, Siemens Digital Industries Software, said, “Siemens consistently delivers on its commitment to leveraging AI to streamline processes and workflows, minimize manual tasks, and accelerate time to market throughout the engineering lifecycle. The latest enhancements in Simcenter Testlab illustrate our approach to integrating AI in order to transform how teams conduct, manage, and interpret physical testing. We are leading a significant shift in engineering practices, from design and development through to the essential stages of physical testing.”

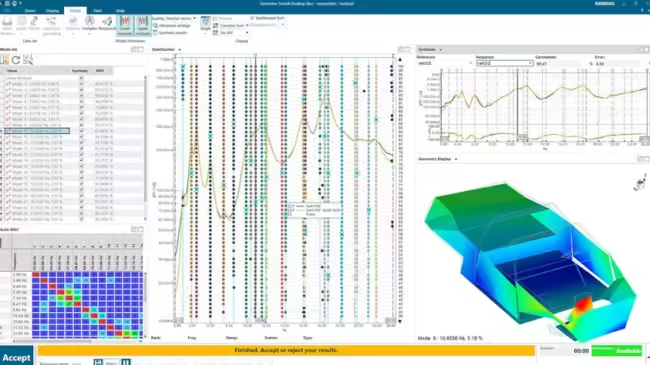

At the forefront of this test automation revolution is the groundbreaking AI-assisted modal testing capability, which speeds the modal analysis workflow up to 700 percent via enhanced automated mode selection and validation combined with a unified modal analysis dashboard that streamlines the entire modal testing workflow. Furthermore, intelligent sensor placement and automated hit selection simplifies the impact acquisition and reduces the personnel required.

Enhanced Testing and Analysis Tools

- Transfer Path Analysis (TPA): New automation features and processing capabilities in Simcenter Testlab cuts overall analysis time by 40%, making sophisticated NVH predictions more accessible to less experienced users.

- First ISO 20270-compliant solution: Cut the time it takes for component characterization from weeks to hours through automated acquisition of blocked forces and impedance FRFs with automated component model extraction solution using Simcenter physical testing hardware and new Simcenter Testlab Automated Component Model Extractor software.

- Streamline test preparation: Use predefined sequences to automate data processing and validation in Simcenter Testlab Schedule Designer to help ensure complete data traceability and virtually eliminate the risk of incomplete or inconsistent test data.

Seamless integration with test hardware

The latest update also seamlessly transfers test plans defined in the Schedule Designer to Simcenter™ SCADAS RS data acquisition system Recorder App. This integration provides clear, wireless tablet-based instructions to operators and enables immediate data validation and processing and thus reduces errors.

In keeping with Siemens’ philosophy of openness, Simcenter SCADAS RS now also allows to export data in universal or third-party formats, so the system can work with other software platforms for data processing and analysis.

COMMENTS