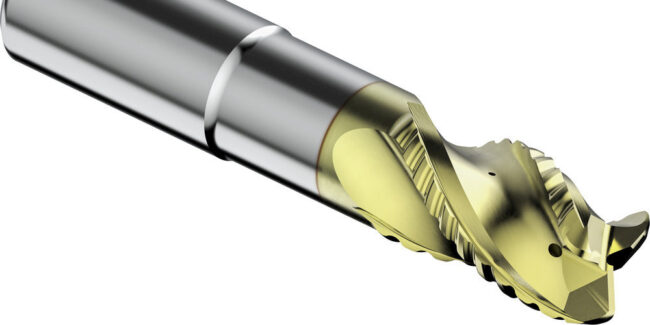

SECO Tools recently introduced the future of Solid End Mills for advanced roughing, where performance meets precision and versatility meets vision. The HP4931 and S4931 Solid End Mills are engineered to address the full spectrum of machining challenges, ranging from high-power aerospace operations to intricate general engineering tasks.

Versatile end mills for aluminium

Covering all aluminum milling needs, HP4931 and S4931 form a dynamic duo for diverse machining environments. HP4931 is designed for speed and strength, delivering metal removal rates exceeding 16L/min through advanced geometry and coolant delivery. In contrast, S4931 offers finesse and flexibility for low- and medium-power machines, featuring a light cutting action and extended reach for deep-pocket applications.

The challenge of one-size-fits-all tooling failing to meet modern machining demands is met with SECO’s solution: HP4931 and S4931. These tools are engineered to span the full range—from high-speed, high-volume aerospace cuts to intricate, lower-power operations—empowering users to optimize every job, every time.

15% longer tool life with advanced coolant design

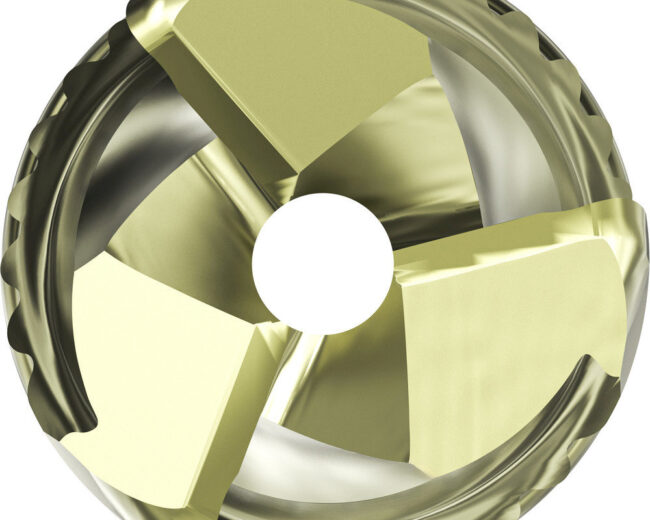

Both tools are equipped with next-generation coolant solutions. HP4931 features a unique configuration compatible with both MQL and emulsion systems, reducing built-up edge and extending tool life by up to 15%. S4931, on the other hand, integrates a central coolant hole for clean swarf evacuation and thermal control—perfect for tight spaces and complex geometries.

Inconsistent coolant delivery can result in tool wear, heat buildup, and process instability. SECO’s HP4931 and S4931 Solid End Mills address this challenge with tailored coolant strategies designed to suit both your machine’s power and the complexity of your application—ensuring a cool, clean, and future-ready machining process.

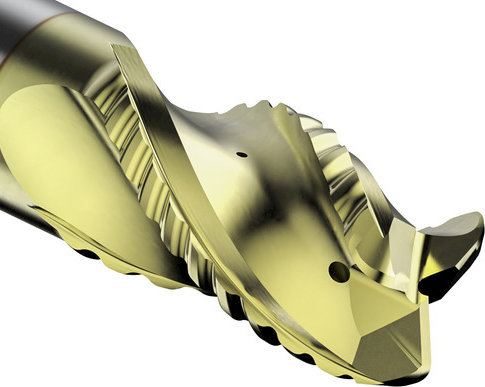

Smart geometries for complex cuts

HP4931’s 3-flute variable pitch geometry, polished AXT coating, and frontal tooth design are optimized for high-volume Z-axis operations and extreme spindle speeds. S4931 mirrors this intelligence with a lighter geometry, three length variants, and the same advanced coating—delivering stability and performance across a wide range of setups from dynamic milling to helical ramping.

Modern machining demands tools that can adapt to varying materials, speeds, and part geometries. SECO’s HP4931 and S4931 Solid End Mills meet this challenge with a shared design philosophy—smart geometry, balanced performance, and adaptability—ensuring reliable results whether cutting fast or cutting fine.

Sustainable, Regrindable, Responsible

Both tools are designed with the future in mind—not just in performance, but in sustainability. Regrindable and long-lasting, they help reduce waste and tooling costs while supporting your environmental goals.

Rising costs and growing sustainability demands are reshaping tool selection in modern manufacturing. SECO’s HP4931 and S4931 Solid End Mills meet this challenge by delivering high-performance machining across multiple applications while maintaining a low environmental footprint—supporting an efficient, adaptable, and responsible future.

COMMENTS