Bringing innovation to the forefront of sheet metal forming, BÖHLER, a voestalpine company, hosted an exclusive technical seminar on ‘BÖHLER’S Tooling Solutions for Enhancing Performance’ on November 7, 2025, at DoubleTree by Hilton, Chinchwad, Pune.

The seminar served as an engaging platform for industry professionals, toolmakers, and manufacturing experts to explore the latest advancements in tooling technologies for sheet metal forming. Attendees gained valuable insights into how material science and surface engineering can enhance tool life, durability, and overall productivity.

The event featured technical presentations focused on advanced steel grades and PVD coating technologies. Experts from BÖHLER shared perspectives on optimizing performance through the right combination of materials, heat treatment, and coatings which showcased as the key factors in achieving precision and consistency in forming operations.

The seminar commenced with a traditional lamp-lighting ceremony graced by Mr. Manfred Nocker, Product Manager, Cold Work Tool Steels, voestalpine BÖHLER Edelstahl GmbH & Co KG; Mr. Lukas Stelzer, Technology- Tooling, voestalpine Böhler Edelstahl GmbH & Co KG; Mr Sandeep Mahalle, Chief Sales Manager, Tool Steel and HSS, BÖHLER India. They were joined by Sachin Salunkhe, Director, Galaxy Tooling; Mr. Sachin Patil, Partner, Galaxy Tooling and Mr. R Vijay Bhaskar, Director Design, M/s Jyoti Technical Services (P) Ltd.

Optimizing Tool Life through High-Performance Steels and Coatings

Following the ceremony, Mr. Stelzer delivered an insightful presentation highlighting BÖHLER’s tooling solutions designed to enhance performance in forming operations

In his detailed presentation, Mr. Stelzer emphasized how investing in high-quality steels can significantly reduce long-term manufacturing costs by enhancing tool life, minimizing wear, and lowering downtime. Addressing key tool failure mechanisms such as abrasive and adhesive wear, fatigue, and processing errors, he explained how BÖHLER’s advanced alloy compositions, precise heat treatments, and surface finishing techniques help manufacturers achieve superior hardness, toughness, and fatigue resistance.

He showcased premium grades such as Böhler K110 (1.2379 equivalent), Böhler K340 ISODUR (remelted steel), Böhler K390PM MICROCLEAN (powder metallurgical steel), and the newly introduced Böhler K888 Matrix, designed to combine high hardness (up to 64 HRC) with exceptional toughness and compressive strength.

Enhancing Tool Life with Advanced Coating Technologies

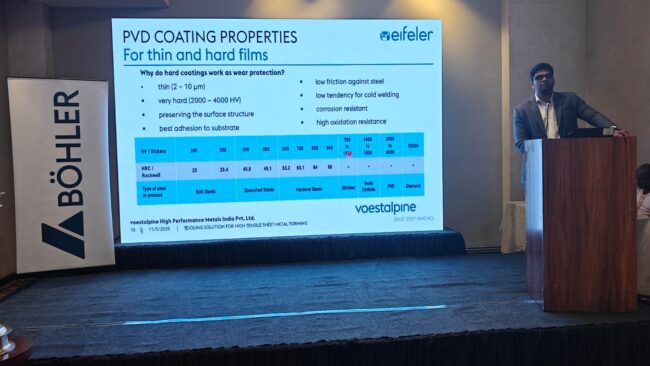

Mr. Sathyanandhan, delivered a detailed session on Physical Vapor Deposition (PVD) technology. He explained how advanced coatings enhance tool performance in metal forming and die-casting applications. PVD involves evaporating material and depositing it on a cooled surface under vacuum to create a thin, hard, and wear-resistant layer, typically 3 – 6 microns thick with hardness levels between 2000–4000 HV. Emphasizing the importance of surface preparation and heat treatment, the presentation noted that proper cleaning, polishing, and substrate smoothness are critical for coating adhesion and durability. As forming operations increasingly deal with high-strength materials, PVD coatings have become essential for minimizing wear, reducing friction, and extending tool life, thereby improving productivity and process reliability across the tooling industry.

Panel Discussion: Evolving Needs and Opportunities in Sheet Metal Forming

The technical seminar concluded with an engaging panel discussion moderated by Mr. Nishant Kashyap, Editor, TAGMA Times. The panel featured Mr. Manfred Nocker, Product Manager, Cold Work Tool Steels, voestalpine BÖHLER Edelstahl GmbH & Co KG; Mr. Lukas Stelzer, Technology – Tooling, voestalpine Böhler Edelstahl GmbH & Co KG; Mr. Vijay Bhaskar, Director Design, Jyoti Technical Services (P) Ltd.; and Mr. Nithyanand Thevar, Managing Director & Founder, Jyoti Tooling.

The discussion focused on the evolving demands in sheet metal forming and the growing importance of advanced tool steels capable of withstanding ultra-high-strength materials. The discussion highlighted how the industry is moving toward lightweight and high-performance components, requiring innovations in materials, coatings, and process optimization. Panellists emphasized the need for greater collaboration between toolmakers, solution providers, and academia to drive innovation, enhance productivity, and build a globally competitive tooling ecosystem aligned with India’s manufacturing growth ambitions.

Conclusion

The seminar brought together industry experts to exchange insights on the latest advancements in tooling steels and coating technologies, highlighting how innovation and skill development are shaping the future of manufacturing. As India strengthens its position in the global manufacturing landscape, the tooling sector is evolving in tandem. By merging voestalpine BÖHLER’s global expertise with India’s growing capabilities, the event reinforced a shared vision for a more advanced, sustainable, and technology-driven tooling ecosystem.

COMMENTS