By leveraging PowerShape & PowerMill, Prime Graphite has streamlined their design and manufacturing processes, improved efficiency, and achieved a new level of precision in their operations.

Prime Graphite Pvt. Ltd., located in Nashik, is one of India’s oldest graphite machine shops. The company has been around for over two decades and delivers superior-quality graphite products to industries that demand high precision and reliability, including die and mould, aerospace, automotive, and electronics. Prime Graphite also excels at offering technical support to help customers improve their operations, decrease waste, and increase efficiency. It exclusively represents Japan-based Tokai Carbon Co. Ltd. in India.

Beginning with machining

In 2008, Prime Graphite ventured into machining operations with one VMC. It initially relied on basic design and manufacturing tools. However, the company faced several challenges such as creating precise toolpaths for elaborate electrode designs, achieving micron-level accuracy in high-precision applications, and managing complex projects that exceeded their machines’ physical limitations. Moreover, the complexity of designing intricate graphite components led to inefficiencies in production, increased material wastage, and longer turnaround times. These challenges prompted them to explore advanced CAD/CAM tools that could streamline operations, reduce waste, and foster innovation.

“I was clear from the very beginning that we wanted to set ourselves apart from the masses and focus exclusively on precision graphite machining. Achieving this required the right combination of technology and skilled manpower. With this vision in mind, we began exploring the best design and programming software to ensure excellence in our work,” said Ashish Chandra Varma, Founder & CEO, Prime Graphite.

The Solutions

To overcome these challenges, Prime Graphite invested in Autodesk’s PowerMill and PowerShape software to strengthen their design and machining capabilities.Autodesk software is highly customizable. Over 25 macros for Prime Graphite were developed, including auto toolpath generation based on templates, toolpath renaming, and toolpath verification to achieve high productivity and efficiency. “By implementing macros in our workflow, we have significantly reduced programmer effort. Previously, an 8-hour shift would yield around 13 hours of machining output. With the software, that same shift now delivers up to 18 hours of output. This efficiency gain has enabled us to increase the number of machining projects we can complete. These enhancements streamline repetitive tasks, minimize manual input, and improve overall efficiency by 25%,” saidAtul Sonar, Sr Manager – Operations, Prime Graphite.

Consequently, Prime Graphite could generate precise and consistent toolpaths to meet tight micron tolerances, encounter minimal errors, reduce manual intervention, enhance speed and augment their daily production cycles. They commended PowerMill for its precise toolpath calculations, which enable sophisticated 3- to 5-axis machining.

Elaborating on the capabilities of PowerMill, Sonar said that they programmed all their machining processes in PowerMill and got flawless results. However, when they faced the challenge of machining electrodes twice the size of their machine’s capacity, they turned to PowerMill’s simulation and validation capabilities. By developing a double-setting technique, they first machined the 700-mm section and then seamlessly aligned the remaining portion through precise calculations. This approach allowed them to achieve flawless results. Autodesk’s PowerMill has empowered them to achieve what was once considered impossible. The precision and customization it offers has redefined their capabilities.

Prime Graphite also commended Autodesk’s PowerShape for its versatility in CAD modelling, particularly its ability to construct and repair models smoothly. With PowerShape, Prime Graphite was able to create highly detailed 3D models, enabling precise simulations that helped identify and eliminate design flaws early, reducing material waste and production errors.

PowerShape’s functionality facilitated geometry development for CAM programming and ensured seamless interaction with PowerMill, easing their machining workflows and providing greater precision in graphite electrode manufacturing.

“The results were clear within months. We saw a 30% cut in production time, a 20% drop in material waste, and a 50% reduction in rejections. Our design accuracy also improved significantly. These changes not only saved costs but also boosted customer satisfaction, helping us build a stronger reputation as a trusted name in precision graphite machining. The drop in material waste also made our operations more sustainable, which is an important step toward environmentally responsible manufacturing,” said Sonar.

Transforming Manufacturing with Autodesk

With the latest software and machines, Prime Graphite is growing quickly, serving some of the biggest names in the manufacturing industry. Over time, customers’ expectations for precise graphite parts have been rising. Now, they not only demand higher accuracy but also faster delivery. To meet this demand, Prime Graphite invested in additional VMCs and Autodesk solutions.

Impressed with the smooth transition to Autodesk’s digital solutions, Prime Graphite later implemented Autodesk Fusion, a cloud-based CAD/CAM solution, which integrates design, manufacturing, simulation, and data management in a single solution. The company has recently started using Autodesk Fusion, working closely with the Autodesk team to explore its capabilities. The software offers ease of programming and significantly boosts productivity in CAM operations. The early results are promising, showing a potential efficiency improvement of around 30%, said Varma.

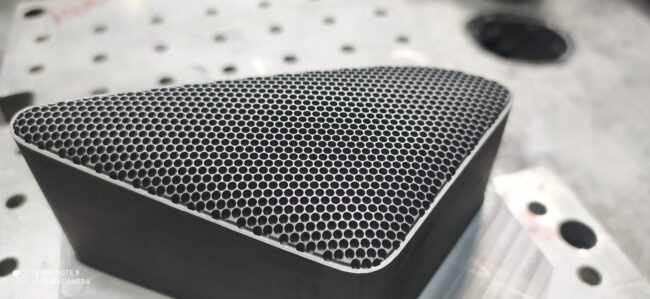

With Autodesk’s advanced manufacturing software and modern machines like VMCs, EDM machines, and CMMs, Prime Graphite now produces over 300 graphite electrodes a day, supporting die and mould jobs, insert finishing and EDM machining. “Our growth is proof of our hard work, skilled team, and investment in the right technologies. Autodesk has been a key part of this journey. The easy-to-use interface, automation, and accuracy of Autodesk software have helped us scale our operations. We highly recommend it to any company looking to innovate and grow,” concluded Varma.

Prime Graphite’s journey with Autodesk highlights the transformative impact of digital manufacturing solutions in today’s competitive landscape. By leveraging PowerShape, PowerMill and now Autodesk Fusion, they have streamlined their processes, improved efficiency, and achieved a new level of precision in their operations. Their success is an inspiration for manufacturers looking to adopt more sustainable products, thereby improving productivity and efficiency.

COMMENTS