HASCO has enhanced its multi-coupling system, which enables the central connection of multiple temperature control circuits in a single step, supporting greater efficiency and process optimisation in mould temperature control. The system features secure locking and user-friendly handling, helping reduce set-up times while reliably preventing connection errors.

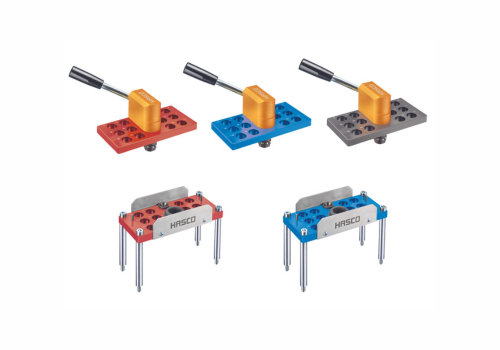

As part of the latest expansion, HASCO has introduced colour-coded base plates to its product range. The new coloured versions allow immediate visual identification of inflow and outflow connections on the mould, further improving clarity on the shop floor and enhancing overall process reliability.

The multi-coupling system is available in different versions. In addition to the classic HASCO standard, the USA (ZI) and French (FRA) systems are available, either as open or closed versions with valves. HASCO also offers the low-leakage multi-coupling system exclusively as an HT version with flat-sealing end faces, which reliably prevents the escape of temperature control fluid during decoupling. The temperature resistance of the multi-couplings has been increased to 180°C for water applications, which brings considerable competitive advantages.

The individually configurable systems in 6-, 12-, and 20-port versions score points with their modular design and wide range of possible combinations with nipples, couplings and hoses. The expanded range of services offers flexible solutions for a wide variety of applications in temperature control technology.

With high product quality, modular standards, and over 50 years of experience, HASCO is a reliable partner for the global mouldmaking and plastics industry.

COMMENTS