ANCA is set to showcase its full suite of innovations at Metalex 2025, reinforcing its position as the partner for high-quality tools and profitability. This year also marks ANCA Group’s 20th anniversary in Thailand, celebrating two decades of precision, innovation, and customer success in the region.

At Metalex, ANCA will feature live demonstrations of its flagship FX5 ULTRA grinding machine, delivering ultra-precision, flexibility, and efficiency across a wide range of cutting tools. Visitors will also experience InsertsPRO, ANCA’s revolutionary software for indexable and special insert grinding, designed to simplify setup, reduce downtime, and enhance productivity.

InsertsPRO is a universal, high performance software platform for indexable and special insert grinding that dramatically reduces setup or changeover time, lowers production cost, ensures firsttime correctness with advanced simulation, and integrates seamlessly into existing ANCA workflows.

Additionally, ToolRoom RN35 and AIMS Connect will be on display, showcasing ANCA’s integrated smart factory solutions. These technologies are designed to help manufacturers unlock hidden efficiencies, reducing cycle times, optimizing feed rates and paths, and ultimately ensuring higher profitability.

“Metalex is an important platform for connecting with our customers and showing the tangible benefits of our technology,” said ANCA’s Jake Farragher, General Manager – Asia. “Our machines and software solutions combine ultra-precision, automation, and data-driven insights to deliver measurable improvements in efficiency, consistency, and overall cost of ownership.”

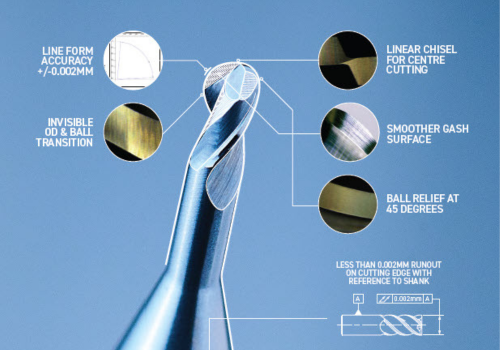

ANCA’s technology is engineered for high-quality, repeatable performance, with features that drive real-world impact:

- Ultra Technology: Complete hardware and software integration for maximum accuracy.

- Precision Engineering: Grind complex geometries and intricate tool designs.

- Automation with AIMS: Error-free, repeatable production.

- Unmatched Consistency: Flawless quality from the first tool to the thousandth.

- Incremental Product Improvements: up to 30% cycle time gains through feedrate optimization and automation.

- Customer-Centric Flexibility: One machine, endless possibilities, supporting industry diversification.

The ANCA booth will feature interactive demonstrations, expert guidance, and hands-on experiences to illustrate how its machines, software, and connected solutions deliver precision, efficiency, and profitability for diverse industries – including automotive, aerospace, medical, and general engineering.

With ANCA, discover more at Metalex 2025, Hall 103, Booth BQ35, and see how advanced technology, integrated software, and smart automation combine to unlock hidden efficiencies and maximize tool performance.

COMMENTS