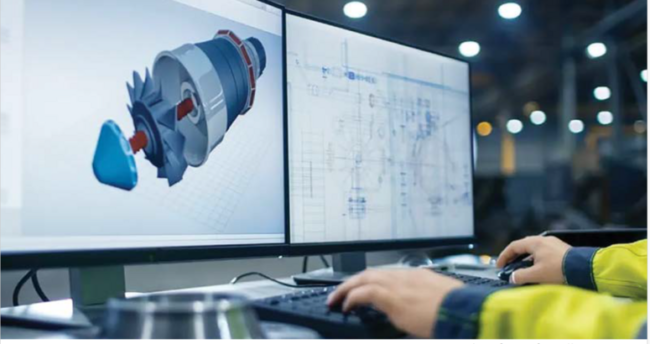

The transformation of CAD/CAM technologies has dramatically reshaped the die and mould industry, driving precision, efficiency, and flexibility across design and manufacturing workflows. From the manual drafting days to the current era of cloud-powered collaboration, AI-enhanced automation, and lifecycle integration, CAD/CAM systems are empowering manufacturers to respond to global challenges, improve

product quality, and reduce lead times. This article highlights the significant role of CAD/CAM in driving smarter, faster, and more sustainable manufacturing.

-Neha Basudkar Ghate

For centuries, drafting was a manual and essential craft across engineering, architecture, and manufacturing. Draftsmen meticulously translated engineers’ sketches into precise technical drawings using pencils, rulers, compasses, and protractors. These hand-drawn plans, often created on large drafting tables, remained the industry standard for centuries, despite being time-consuming and prone to human error.

The landscape shifted dramatically with the advent of Computer-Aided Design (CAD) in the 1960s. Initially adopted by the aerospace and automotive industries, early CAD systems were expensive, room-sized machines, but they offered faster, more accurate results. As CAD became more accessible, it revolutionised design workflows across multiple sectors. Alongside CAD, Computer-Aided Manufacturing (CAM) emerged, bridging the gap between design and production by automating machining processes, reducing reliance on manual labour, and redefining the role of engineers and draftsmen.

Fast forward to the current scenario, the global manufacturing landscape is rapidly evolving, with digitisation and decentralisation driving the need for greater precision and agility, particularly in the die, mould, and toolmaking sectors. Integrated CAD/CAM technologies, once limited to design and machining, have become strategic enablers of smart manufacturing, empowering companies to enhance product development, ensure quality, and coordinate complex, distributed operations across geographies.

Design and Manufacturing Integration Streamlines Workflows

In the traditional die and mould industry, design and manufacturing are often handled independently, resulting in miscommunication, rework, and costly delays. However, integrated CAD-CAM workflows are breaking down these barriers. Describing this shift, Amol Mane, Director – Sales and Marketing, Cimatron (Southeast Asia, India, Middle East, ANZ, and South Africa), states: “In the mould and die industry, the integration of CAD-CAM has become essential to streamline design to manufacturing workflow and reduce the cost of poor quality due to frequent design changes (engineering change orders), which lead to rejection/rework. Traditionally, toolmakers worked with separate platforms for design and manufacturing of moulds and dies, leading to potential rework/rejection, and hence, increased cost of poor quality (COPQ) and delayed deliveries.”

This transition from fragmented systems to unified platforms is redefining how manufacturers approach design iterations and production feedback. Integrated CAD-CAM tools allow real-time updates to be reflected across systems, enabling toolmakers to respond faster to design changes and customer requirements. By synchronising data across departments and reducing duplication of effort, manufacturers can significantly minimise rejection rates and accelerate time to market.

Today, manufacturers are investing in systems that seamlessly integrate design revisions into production processes. Smart CAD-CAM systems are no longer passive tools; they are active enablers of agility and competitiveness.

The China+1 Strategy and Regional Readiness

As global production dynamics shift, the China+1 strategy has brought the spotlight on emerging manufacturing destinations like India, Vietnam, and Mexico. This shift is not merely about geography; it demands more responsive, localised, and standardised production strategies. Sunil Desai, Founder Director, TopSolid India, elaborates: “The manufacturing landscape is witnessing a fundamental shift. As global production hubs diversify, countries like India, Vietnam, and Thailand are emerging as significant players in the manufacturing ecosystem. While the China-plus-one strategy is creating new dynamics, it’s imperative for companies to leverage technology to stay competitive. The die and mould industry, being highly specialised, is leveraging these developments to remain agile and responsive to market needs.”

Vineet Seth, Managing Director – South Asia & Middle East, Mastercam APAC, adds: “As companies diversify their production bases beyond China, there is a heightened need for flexible, standardised, and highly adaptable processes that can be replicated across different geographies without the loss of quality or productivity. CAD/CAM systems have enabled this transition.”

This strategic shift will require manufacturing systems to be flexible and adaptable, emphasises Mane. “The China-plus-one strategy is reshaping the global manufacturing landscape, as companies diversify their supply chains away from China, turning to markets like India, Vietnam, and Mexico. This strategic shift requires manufacturing systems that are flexible and adaptable, capable of handling design changes across multiple regions and manufacturing processes. An integrated CAD-CAM solution helps manufacturers meet these demands by offering streamlined workflows that enhance productivity, reduce rework/rejection and ensure that the final product meets the highest standards of quality. As global markets continue to evolve, the ability to seamlessly integrate design and manufacturing, while staying agile in the face of shifting supply chains, will be a crucial factor for success,” he explains.

How Smart Manufacturing Enhances the Ecosystem

Smarter manufacturing today demands real-time data exchange, faster iteration cycles, and predictive capabilities that anticipate issues before they disrupt production. Traditional methods often delayed critical decisions, especially when simulations or physical prototypes took days or weeks. But with the advent of AI, IoT, and connected systems, manufacturers can now respond to design and production feedback instantly, enabling continuous improvement and operational agility.

Commenting on how these developments are empowering tool rooms, Desai says: “Prototyping is becoming more accessible, and manufacturers are integrating digital twins and IoT connectivity to ensure continuous feedback from the shopfloor. With automated CNC machining and AI-assisted process optimisations, manufacturers can now optimise material usage, reduce waste and ensure consistent quality at every stage of production.”

Today, CAD/CAM and PDM integration is not just about designing tools; it’s about delivering smarter, more flexible manufacturing solutions that adapt to evolving market demands. This involves the integration of Virtual Reality (VR) for quick design adjustments, the shift towards collaborative manufacturing, and an increasing focus on prototyping to accelerate product development.

“AI is revolutionising CAD by enabling real-time predictive simulations, allowing designers to receive instant feedback on design properties without lengthy simulations. This accelerates the design process and facilitates the exploration of unconventional geometries. AI also detects design flaws and optimises geometry based on historical data, making complex tools accessible to more users. IoT plays a pivotal role in receiving data from CNC machines and other feedback systems in real time, resulting in bi-directional responsive systems creating digital twins that simulate real-world performance. 5G enhances this ecosystem with ultra-fast connectivity, enabling real-time collaboration, improving smart factory logistics, and ensuring seamless updates between CAD models and IoT-connected environments,” Desai adds.

Mane expresses: “With the rise of smart manufacturing technologies, AI, and real-time data processing, the CAD-CAM industry is now evolving to ensure that design changes are automatically synchronised with manufacturing systems, improving both efficiency and quality of the finished product, reducing the dependency on the skill level of the workforce.”

Optimising Customisation with Intelligent Toolpaths

Die and mould manufacturing has always been a domain of high customisation and intricate geometries. Each project typically involves one-off designs, tight tolerances, and unique surface treatments, leaving very little room for standardisation. This complexity has historically posed significant challenges in maintaining efficiency and repeatability. However, today’s CAD-CAM platforms are meeting these challenges with intricate and intelligent solutions designed to optimise every step of the process.

Seth elaborates: “Customisation and complexity go hand-in-hand with die and mould manufacturing, with every component demanding distinct geometries, tolerances, and surface treatments. Modern CAD/CAM systems have risen to this challenge by embedding intelligence across both modelling for manufacture and machining workflows, allowing manufacturers to achieve rapid turnaround without compromising on precision or quality. Toolpaths have evolved to keep the cutting tool engaged in a more consistent, efficient way, which means less wasted movement, faster machining, and ultimately, less leftover material.”

The benefits are not just in terms of speed or material usage; they extend to quality assurance and risk mitigation. “Advanced verification tools allow manufacturers to detect collisions, over-travel, gouging, and inefficient tool engagement during the programming and verification phase. These are not abstract concepts, but they are becoming real tools that manufacturers can plug into their workflows right now. Designed to work alongside programmers, Copilot will suggest strategies, catch potential oversights, and learn from the way a shop prefers to machine, making it less about replacing expertise and more about amplifying it. Ultimately, AI isn’t pushing skilled machinists or programmers out of the picture. It’s becoming an extension of their capability,” Seth continues.

A Key Takeaway

The die, mould, and toolmaking sectors are undergoing a fundamental transformation, powered by the integration of CAD/CAM technologies. What was once a fragmented process, with design and manufacturing operating in silos, is now evolving into a synchronised, intelligent workflow. The shift to integrated platforms is helping manufacturers reduce rework, lower costs, and improve turnaround times by ensuring real-time coordination between design changes and production processes.

Across the industry, there’s a clear push toward flexibility and standardisation, especially as companies diversify beyond China and expand into new manufacturing regions like India, Vietnam, and Mexico. This global realignment demands manufacturing systems that can easily adapt to different geographies without sacrificing quality. CAD/CAM technologies are proving crucial in enabling this transition, allowing companies to scale their operations efficiently while maintaining consistency and precision.

At the same time, digital technologies such as AI, IoT, and real-time data exchange are making manufacturing more responsive and intelligent. These tools allow manufacturers to catch design flaws early, optimise machining strategies, and reduce waste while improving quality. From digital twins and VR-based prototyping to smart toolpaths and AI-assisted decision-making, the modern tool room is becoming a high-tech environment where data, machines, and human expertise work in sync.

Ultimately, CAD/CAM systems are no longer just tools. They are strategic assets enabling smarter, faster, and more sustainable manufacturing by merging design, production, and quality control into one continuous, connected process. As complexity grows and global markets evolve, embracing these technologies is not just beneficial but essential for staying competitive.

Upskilling for the Digital Age

The transformation of CAD/CAM is not just about technology—it’s about people. As software capabilities evolve, there’s a growing need for skilled professionals who can leverage these tools effectively. Proficiency in CAD/CAM/CAE systems, cloud-based collaboration, and data-driven decision-making is becoming a prerequisite across manufacturing organisations. Educational institutions, industry bodies, and software vendors must collaborate to upskill the next generation of toolmakers, machinists, and design engineers. Investing in continuous learning, certifications, and hands-on exposure to the latest tools will be essential to bridge the talent gap and ensure long-term industry resilience.

The Road Ahead

The CAD/CAM industry stands at a pivotal moment, poised between tradition and transformation. It is no longer merely a technical utility but a strategic enabler of smarter, faster, and more sustainable manufacturing. Whether it’s through cloud collaboration, AI-powered automation, or lifecycle integration, CAD/CAM systems are becoming the digital backbone of the modern industry.

As manufacturing increasingly becomes decentralised, customised, and data-driven, the demand for agile, intelligent, and integrated CAD/CAM solutions will only grow. For tool and die makers, embracing these innovations is not optional, but imperative. The future of manufacturing is being designed and machined today. And CAD/CAM is leading the change.

This article was published in TAGMA Times

COMMENTS