A new universal injection molding platform, progressive co-injection technology, an 85-foot extruder line with live cobot demonstrations, in-mold foil decorations, exclusive IIoT digital solutions, and more on display this May.

Milacron, a global leader in the manufacture, distribution, and service of highly engineered and customized systems within the plastic processing industry, will demonstrate advanced equipment solutions, innovative mold technologies, and comprehensive service and support systems at NPE May 6-10 in Orlando.

A pioneer in the plastics processing industry, and one of the largest North American-based OEMs, Milacron is set to showcase its latest advancements and innovative solutions, including the North American debut of its new M-Series IMM platform that features the largest clamp stroke available as standard in the mid-tonnage hybrid range within a compact footprint. Powered by industry-leading Fanuc motors and drives, the versatility and performance of the M-Series are designed to meet the demanding needs of global industries, from automotive and consumer goods to packaging and custom molders.

Booth W1601, the largest exhibit space at NPE 2024, is designed to offer attendees an array of plastics processing technologies. In addition to its M-Series machine line, Milacron’s showcase includes several work cells and industry-leading exhibits, alongside innovations from fellow Hillenbrand Operating Companies Coperion, DME, Herbold, Mold-Masters, and Rotex.

“Much has evolved in the plastics processing space since we were all last together at NPE 2018, including our integration into the Hillenbrand family of leading industrial brands,” said Mac Jones, Milacron President. “Our sizeable presence at NPE 2024 underscores Milacron’s drive to deliver solutions that Shape What Matters For Tomorrow™ in the plastics processing industry.”

Two different M-Series machine applications are planned for the booth. The M-1070, featuring Mold-Masters co-injection technology, is a two-cavity-mold pail application with up to 50% recycled core and includes IML (In-Mold Labeling) automation. The M-500 machine cell features a Mold-Masters hot runner and Kurz in-mold decoration technology for custom textures and backlit applications in global automotive and appliance applications.

Several variations of Milacron’s durable, general-purpose, high-performance Q-Series platform will be present. The Q-Series features a double-toggle design that leverages a servo-hydraulic package delivering quality parts at a rapid pace while minimizing energy use. At the Milacron booth, the Q-170 machine displays a new G3 Mosaic control, DME mold technologies utilizing a bio-resin material, as well as custom ID/serialization and QR code stamping. A mobile phone holder will be the Q-170’s featured application. Additionally, Milacron’s Q-125 will be active in the Sepro booth (W143), where four private-labeled Sepro robots will integrate with the machine to produce a two-cavity mini disc.

Several variations of Milacron’s durable, general-purpose, high-performance Q-Series platform will be present. The Q-Series features a double-toggle design that leverages a servo-hydraulic package delivering quality parts at a rapid pace while minimizing energy use. At the Milacron booth, the Q-170 machine displays a new G3 Mosaic control, DME mold technologies utilizing a bio-resin material in the application, as well as custom ID/serialization and QR code stamping. A mobile phone holder will be the Q-170’s featured application. Additionally, Milacron’s Q-125 will be front and center in the Sepro booth (W143), where four private-labeled Sepro robots will integrate with the machine to produce a two-cavity mini disc.

Milacron’s all-electric Fanuc Roboshot showcases two different applications within the booth that integrate DME Flosense water manifold technology. The Robo 55 features LSR (liquid silicon rubber) material and automation that is common in automotive, electrical, and medical applications. The cell includes a micro-plunger to precisely control small-capacity volume for the umbrella part produced that requires a tiny shot. Also in the booth, the Robo 275 machine cell shows a 48-cavity medical vial application. Partnering Operating Company, Mold-Masters, displays its new M3 thermocouple technology in this machine, ensuring precise temperature measurement in its Master-Series Pico hot runner with the Accu-Valve MX gate system. An added solution to this cell that makes it ideal for processors requiring a clean room environment, Milacron’s stainless steel water system is also featured on the Robo 275.At the far end of the cell, a platen-mounted robot with a conveyor retrieves the small plastic parts and places them in bins in a space-saving envelope containment area.

The L-Series, Milacron’s LPIM platform, has been at the forefront of the low-pressure injection market for more than fifty years. Wide-ranging molding flexibility and part design are possible through nozzle sequencing. Most notably, the Milacron LPIM machine can run up to 100% regrind flake material, resulting in significant energy and resource savings. This commitment to sustainability offers a competitive advantage to customers in a world increasingly seeking to meet environmental compliance. Due to space constraints, the L-Series will not be featured at the show, but an in-booth animation loop will display the benefits of this industry-leading low-pressure IMM technology for large-part production in structural foam and structural web applications.

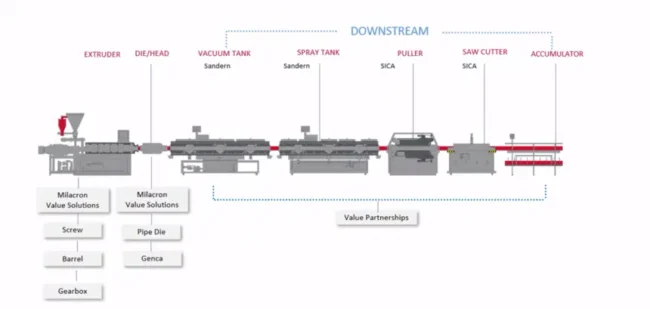

Milacron’s SG75 extrusion pipeline exhibit can’t be missed spanning more than 85’across the center of the booth and featuring a new control that fully integrates all line components. Additional highlights include the gravimetric feeder system, new poly-olefin pipe heads, the latest technology in single/twin screws and barrels, dynamic downstream equipment, and post-production automation. Attendees can view the articulating 6-axis cobot technology at work through live demonstrations.

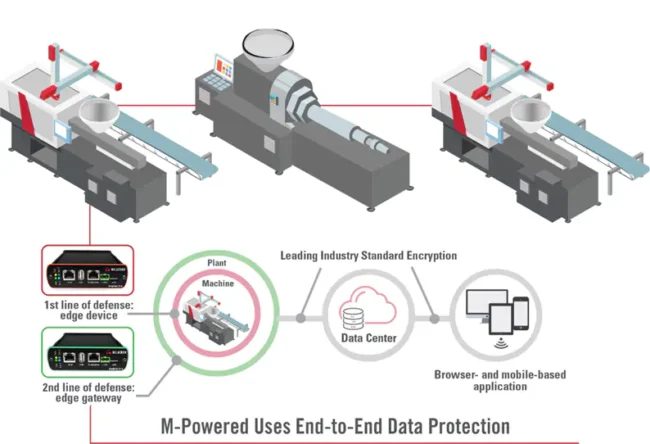

Lastly, show participants can interact with Milacron’s M-Powered digital IIoT solution. A portfolio of easy-to-use observational, analytical, and support services that provide customers with a competitive advantage, improved OEE, and reduced scrap rates, M-Powered leverages IIoT technology through sophisticated algorithms that utilize real-time machine learning to monitor machine operations. Milacron integrates M-Powered onto all its new machines for free for the first 12 months of ownership.

An innovative world leader in plastic processing, Milacron delivers the next generation of manufacturing technology this May for a wide array of industries. From a new IMM platform in the mid-tonnage range to the largest extrusion line the company has ever exhibited, Milacron partners at NPE 2024 with fellow Hillenbrand Operating Companies, as well as some of the top plastics processing partners in the industry, to Shape What Matters For Tomorrow.

IMAGES

The universal M-Series delivers greater versatility, reliability, and improved dry cycle time. The M-Series is driven by a servo motor hydraulic system that offers improved specifications and all-inclusive performance, as well as integrated control. In addition, faster clamp speeds, reliable tonnage assembly, and improved mold and eject access for quicker mold changes deliver optimal productivity and space savings.

The M-Series is a next-generation machine in Milacron’s fleet that showcases cutting-edge two-platen technology and exceptional efficiency, with the ability to integrate multiple co-injection technologies that can support customers’ sustainability demands.

The SG75 extrusion system features a new control, poly-olefin pipe heads, and advanced technology in single/twin screws and barrels. It’s a fully integrated package with all required downstream equipment including a vacuum tank, pullers, saws and much more. At the end of the line, a live cobot will perform demonstrations at the show.

The new extrusion control fully integrates with all line components.

Milacron’s IIoT remote digital solution, M-Powered, leverages real-time machine data that provides unique insights on the plastic manufacturing process. With built-in analytics, the platform provides a clear picture of OEE and helps identify the root cause of downtime, quality issues, and production inefficiencies.

COMMENTS