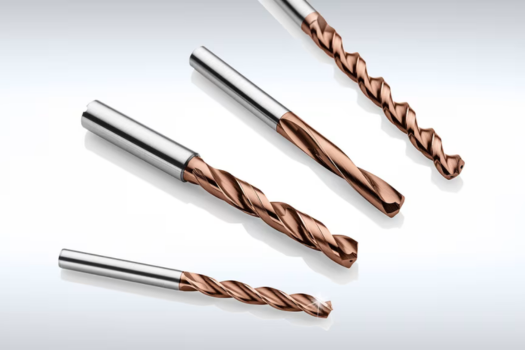

Oerlikon Balzers, a leading technology brand of Oerlikon known for its expertise in advanced thin-film coatings, has unveiled BALINIT OPTURA, a next-generation high-performance PVD coating developed specifically for drilling applications in steel and cast iron. Engineered to address the complex and evolving requirements of modern manufacturing, BALINIT OPTURA is designed to significantly improve productivity, extend tool life, and ensure greater process reliability and versatility when working with a wide spectrum of materials and under varying cutting conditions. This launch underscores Oerlikon’s dedication to providing sustainable, high-efficiency solutions that not only boost productivity but also encourage resource-efficient and environmentally responsible practices within the metalworking industry.

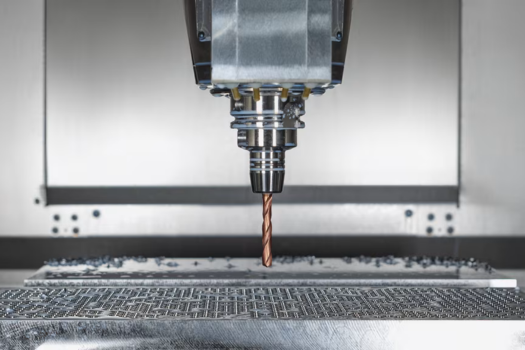

In metal processing, drilling is one of the most critical and often final steps in part production. Ensuring a stable production process – with extended tool service life, high reliability, consistent performance and high-quality boreholes – is paramount in order to achieve optimum productivity and cost efficiency. BALINIT® OPTURA meets these demands through its optimized multilayer coating structure and increased wear resistance, resulting in longer tool service life, enhanced performance and lower manufacturing costs.

In benchmark tests with a Tier 1 automotive supplier, BALINIT OPTURA delivered an average of 89% longer tool service life compared to proven previous-generation coatings. In some cases, the service life of reconditioned drills was even double that of new tools with sophisticated double coatings. This results in lower tool consumption, fewer reconditioning cycles and a significant increase in performance, all of which helps reduce overall production costs while maintaining high borehole quality.

BALINIT OPTURA has demonstrated more reliable performance than current benchmark coatings across a wide range of steel and cast iron grades – from low-alloy to tempered and hardened steels. Whether used in moderate conditions or high-performance drilling, this advanced PVD coating reflects Oerlikon’s commitment to addressing the economic and ecological challenges of today’s competitive metalworking industry. Its performance is defined by the following key benefits:

- Advanced wear resistance increases productivity, boosts performance and reduces costs per part

- Higher process reliability, even when machining demanding steel alloys or performing challenging applications such as deep-hole drilling

- Predictable wear behavior to ensure consistently high borehole quality

- Consistent performance after multiple re-coating cycles, minimizing both costs and environmental impact

“In extensive tests with tool manufacturers and end users across several continents, BALINIT OPTURA has delivered outstanding results,” says Dr.-Ing. Ivan Iovkov, Global Product Manager Cutting Tools at Oerlikon. “With an average performance increase of more than 50% compared to previous-generation and competitor coatings, the newly developed BALINIT OPTURA has proven itself across a wide variety of steel and cast iron materials and cutting conditions in real-world production environments. Its sophisticated coating design and resulting properties extend tool service life and reduce manufacturing costs by up to 33%. We are pleased to announce that BALINIT OPTURA is now available in most countries where Oerlikon works closely alongside its industry partners.”

COMMENTS