Renishaw’s expertise, technology and products span all levels of manufacturing process control, from products which calibrate and measure machine positioning and motion performance, through systems for machine tool automation and versatile gauging, to co-ordinate measuring systems which give traceable verification of component and feature dimensions, say Mr. Paul Weaver, Director Sales and Marketing, India, Renishaw Metrology Systems Limited in conversation with Mr. Nishant Kashyap.

By Nishant Kashyap

What are the current trends and demands you’ve observed in the Indian die mould

industry?

India’s die and mould sector has developed over the years and now holds a prominent position in manufacturing. The industry is growing year on year since it can meet a variety of demands from the growing industries including Automotive, Plastics, Electronics and Electrical, Healthcare and Machine Tools.

There is growing demand for die and molds capable of handling advance materials, such as high strength alloys, composites, and plastics with specific properties. Integration of automation, data exchange and smart technologies into manufacturing (Industry4.0) has been a significant trend. This includes the use of IoT, sensors and data analytics to enhance efficiency and quality. There’s a growing emphasis on sustainable manufacturing practices, including the use of eco- friendly materials, energy-efficient processes, and waste reduction in the die mould industry.

How do you perceive the business outlook for the die mould industry in India in the coming years? Are there specific growth areas or challenges you anticipate?

As per the recent reports the Indian die and mould industry is estimated to grow at a CAGR of

9% approx. The market growth depends on the opportunities with aluminium metal injection

moulding, automation in die-casting process and demand for dies and moulds from construction

activities.

The die mould industry often correlates with the growth of automotive and aerospace sectors. As

these industries are growing in India, there may be increased demand for precision die moulds.

With the rise of Electronics manufacturing, there will be opportunities for die and mould industry.

Many companies are now investing in automation and industry 4.0 technologies to enhance

efficiency and reduce costs, which might drive demand for advanced die moulds capable of

supporting these processes.

While the Indian D&M industry has massive potential & so much to look forward, there are some

clear challenges in meeting increased production demands and quality standards without losing

its cost competitiveness. To capitalize on growth opportunities, the industry needs to adopt

technologies and partner with incumbent technology providers to be able to meet future market

needs and enhance its capabilities and competitiveness.

Can you highlight some of the innovative solutions or products and how these offerings address industry needs?

We will be showcasing our innovative solutions for the die and mould industry. Users will be able to witness the live demonstration of on-machine verification (OVM) using Renishaw technologies and how its beneficial than the conventional methods of die mould inspection.

Some of the technologies on demo will be Renishaw’s:

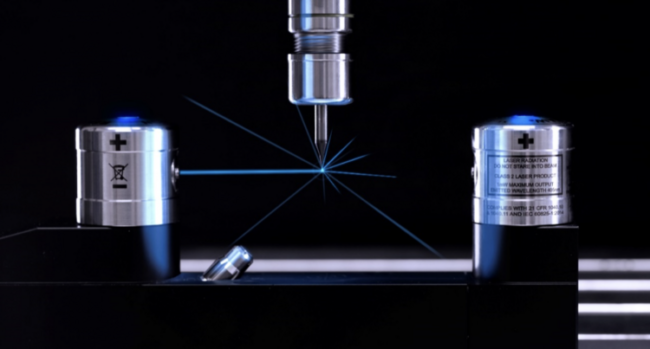

NC4+ Blue – non-contact tool setter for on-machine tool measurement

Featuring industry-first, blue laser technology (patent pending) and improved optics, Renishaw’s NC4+ Blue non-contact tool setting systems deliver significant improvements in tool measurement accuracy, ensuring components can be machined more accurately and efficiently on CNC machine.

Compared to red laser sources found in conventional non-contact tool setters, blue laser technology has a shorter wavelength resulting in optimised laser beam geometry. This enables the measurement of very small tools, whilst minimising tool-to-tool measurement errors – a critical consideration when machining with a wide range of cutting tools.

NC4+ Blue systems use Renishaw’s non-contact tool setting software package, which continues to evolve to ensure rapid, robust, and reliable measurement even in wet conditions. Auto-optimisation technology within the software automatically adjusts the movement of the tool in and out of the beam to minimise any wasted movement and therefore cycle time. While features such as a dual measurement mode, where the tool is measured as it exits the laser beam and an advanced tool cleaning option, help ensure the tool is free from debris and coolant during measurement. Further enhancements to tool run- out and profile measurement cycles deliver increased functionality and reliability to advanced users.

OMP400 high-accuracy machine probe

The OMP400 is an ultra-compact, high-accuracy touch probe that offers all the benefits of automated job set-up as well as the ability to measure complex 3D part geometries on CNC machining centres, including multi-tasking machines. With patented strain gauge technology and interference-resistant optical transmission, the OMP400 provides superior performance found in all Renishaw high-accuracy probes.

Some of the benefits of this technology

Superior 3D accuracy – Delivers unrivalled submicron performance when measuring complex 3D shapes and contours.

Ultra-low trigger force – Unmatched low trigger force for delicate work helps eliminate surface and form damage.

Inspects difficult parts – Improved accuracy when using long and custom styli means difficult parts can be measured with ease.

Robustly engineered – Robust, even in the harshest environments, providing reliable measurement and long service life.

How does your company stay competitive in a dynamic market, and what strategies or technologies do you employ to maintain your position in the industry?

We work closely with a range of players in this sector with the focus on the development and adoption of automation technologies and help manufacturers achieve even more demanding performance and production targets.

Our metrology products help manufacturers to maximize production output, significantly reduce

the time taken to produce and inspect components and keep their machines running reliably. Manufacturers can provide more economical, fast, reliable, and quality dies to the customers so that their customers will produce final component at the earliest and reduce the lead time. Accuracy and on time delivery of projects are key requirements for the die mould industry. Renishaw solutions help tool makers to save time, money, reduce scrap and achieve a high level of accuracy.

What message or value would you like to convey to the Die Mould Industry of India regarding your company’s role in the industry and the benefits of your products or services?

Renishaw’s expertise, technology and products span all levels of manufacturing process control, from products which calibrate and measure machine positioning and motion performance, through systems for machine tool automation and versatile gauging, to co-ordinate measuring systems which give traceable verification of component and feature dimensions. Preventative offers reduce the number of sources of variation before machining starts.

Renishaw Ball bar solution enabling rapid health checkup of machines, reducing

downtime losses and rejection rates –

Several times the machining of dies suffers from variation due to positioning accuracy, squareness of axis & interpolation of two axis. Pitch errors also plays a critical role in positioning accuracy of dies. If the machine down time is more, it will result in production delays. The current method includes manual checkup of the machine, which is time consuming as it involves removing cover and fixture. Ballbar will check the health of machine in 10 – 15 mins without having to remove cover & fixture. It highlights issues & appropriate actions are performed to qualify the component.

Process setting offers are applied just before machining starts.

Automatic die alignment – Die alignment by using dial gauge is again a time-consuming process. After die loading probe will take two points on die & will update the angle in plane rotation so that manual alignment process will be eliminated. No need to have skilled manpower for die alignment.

Automatic work offset – Its manual process & need human skill. Also, its time-consuming process. But Probe will check dowel reference / corner and will update automatically so that machining will start without manual intervention.

Automatic tool offset – Normally tool updation process is manual process & customer will update tool by touching to the die. It may lead to variation in wrong entry. Auto tool length & diameter will eliminate all errors. Also, dynamic checking of tool diameter will eliminate errors due to spindle runout & tool wobbling issue.

Tool Profile inspection – Its only feasible with high end tool presetter & playing major role machining 3d profile. Renishaw non-contact NC4 system will provide exact tool radius which will eliminate initial setting errors.

On machine process control solutions controlling thermal variations and reducing rejection rates significantly – Thermal errors have been found to be one of the key reasons for quality issues. Machining of dies is long process (2Hr – 10 days ) & suffer a lot due to large variation in temperature (20 – 48 degrees). This temperature variation causes the axis to expand and impacting the positional accuracy. Majority of machines used in Indian condition are without Ball screw cooling. Use a spindle probe to measure the size of a reference feature in the machine environment and compare it with the known size of that feature at 20 ºC. Probe will check master reference every hour & compensate the error automatically.

In cycle gauging solutions saving time, improving quality, and enhancing capability –

Due to long cycle time probe will check dimension after rough cut or certain interval so that tool wear correction will be automatically updated in Tool length. Also, this will help to regenerate finishing program.

Tool wear control – Die machining is normally long cycle & adds errors due to tool wear. Tool probing system will check variation in length after interval of 1Hr & will automatically update in the controller. Also, probe will identify tool wear in profile will raise alarm if wear is beyond limit.

Post process controls are applied after machining is completed. They provide confidence

in the dimensional conformance of the part.

On Machine verification – Typically molds and dies are large in size and bulky in weight, removing them from machine for verification purposes can introduce a lot of waste in the form of machine down time, time required to analyze results and make necessary corrections or adjustments, time involved by skilled engineers to carry this operation, etc. This can also introduce errors if parts have to be reloaded again for rework. Renishaw offers solutions to verify these molds and dies by measuring their critical features) on machine before unclamping die from the machine and also produce a detailed report (which is similar to CMM reports. The report consists of comparison of CAD model with respect to actual (X, Y, Z & I, J, K Vector) with deviation details. Otherwise after inspection on outside instrument is very difficult and time consuming as it also involves reloading die on original work offset.

COMMENTS