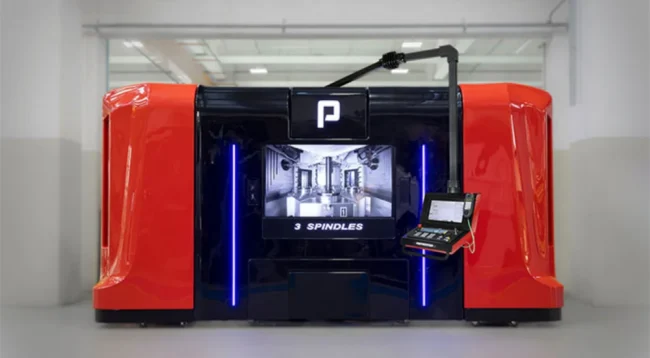

Porta Solutions will showcase its 5th Generation PORTACENTER at EMO 2025 (Hall 15, Stand B2), introducing a machining center designed to deliver unparalleled efficiency and productivity. Equipped with three independent spindles, the PORTACENTER allows manufacturers to machine three parts simultaneously, reducing cycle times and boosting productivity by up to 300%.

The new PORTACENTER also offers fast changeovers, large tooling capacity, and simplified operations, enabling users to seamlessly switch between different components. According to Porta Solutions, the machine helps cut cost per part by 44.5%, making it a compelling solution for competitive manufacturing environments.

Key advantages of the PORTACENTER include:

- Free Feasibility Study – Expert engineers provide a technical consultation to analyze components and propose the best solution.

- Zero-Risk Test Drive – Customers can trial the PORTACENTER with their own components before purchase.

- Fewer Specialized Operators – Automation reduces reliance on highly skilled operators while maintaining high productivity.

- Reduced Tooling Investments – A single machine can replace three machining centers, cutting investment and complexity.

- Fast Delivery – Delivered in 60–90 days and ready to run.

- Dedicated Customer Care – A 20-member team supports training and after-sales service.

With its unconventional design and strong focus on cost-efficiency, Porta Solutions positions the PORTACENTER as a game-changer for modern manufacturing.

COMMENTS