Many professionals in the machine tool industry are most probably familiar with the ER Collet Chuck – a widely used clamping system worldwide. But did you know that Mr. Fritz Weber, the founder of REGO-FIX, invented and patented the ER Collet Chuck in 1972? While “E” in “ER” has been derived from the existing “E” collet series, REGO-FIX ingeniously appended “R” for “REGO-FIX” to coin the name “ER”. This innovation is one among many. Today, REGO-FIX boasts a diverse portfolio of patents, which are a testament to the company’s commitment to research and development. Nishant Kashyap highlights the illustrious legacy of REGO-FIX in producing cutting-edge clamping systems after visiting the company’s manufacturing facility in Switzerland.

REGO-FIX, a company that has set the standard for precision tool holding, offers cutting-edge solutions, such as the ER Collet Chuck system and powRgrip®, which are well-knownfor their ease of use and sophisticated design. Specifically catering to industries that demand high accuracy and reliability, REGO-FIX’s products are an embodiment of their commitment to quality, sustainability, and continuous improvement. Each of their Swiss-made tools reflects their zeal for precision and unwavering dedication to ensure their customers’ success.

A rich legacy defined over the years

REGO-FIX has been a pioneer in the industry since its inception. Its journey of innovation and growth, which began in 1950 took a significant turn in 1972 when the company introduced the ER Collet Chuck, a revolutionary product that became the industry standard.Invented by REGO-FIX Founder Mr. Fritz Weber, the ER Collet Chuck system proved to be a game-changer; it offered unparalleled precision and flexibility. And, by the time it was standardized in 1993, the ER Collet Chuck system had already become the most widely used tool-holding system worldwide.

During the 1970s and 1980s, REGO-FIX continued to innovate. The company’s commitment to quality and precision led to the development of various accessories such as tool holders and clamping nuts, which complemented the ER Collet Chuck system. This period also witnessed the company’s expansion in terms of production and manpower, reflecting the growing demand for its products. As the new millennium unfolded, REGO-FIX had an impressive portfolio of nearly 140 patents spanning over 140 countries, a testament to its pioneering spirit and commitment to machining excellence.

Amidst the global financial crisis of 2008, REGO-FIX demonstrated resilience by embarking on the expansion of its headquarters in Tenniken. This strategic initiative entailed the addition of additional production and office space, symbolising the company’s unwavering commitment to growth. By investing in new machines, refining production processes, and enhancing employee training programs, REGO-FIX positioned itself to navigate future challenges and seize forthcoming opportunities. Presently, REGO-FIX stands as a family-owned and family-operated enterprise, with the second generation of the Weber family guiding its course. At the heart of the company’s identity lies its distinctive blue triangle logo, symbolizing machining excellence, innovative approaches, and a passion for precision.

Facility at Tenniken

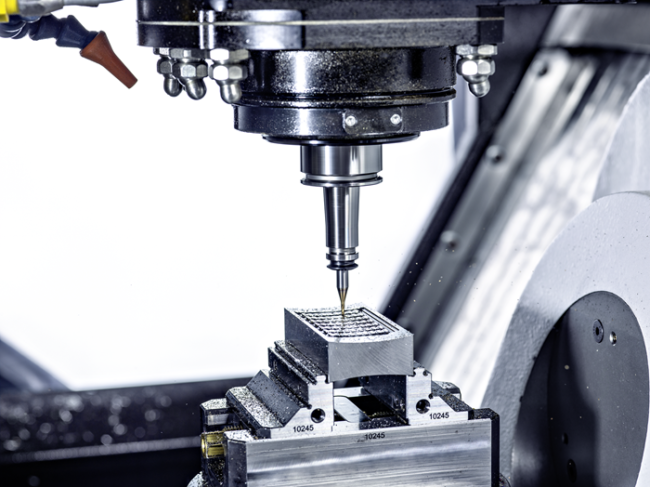

Nestled in Tenniken, Switzerland, REGO-FIX’s sprawling manufacturing facility spans an impressive 12,500 square meters. This facility utilizes ultra-modern technologies and systems to produce cutting-edge tool-holding products. Positioned at the forefront of Industry 4.0, REGO-FIX showcases cutting-edge automated processes and state-of-the-art solutions for quality control and inspection. Complementing this, the facility houses a dedicated skill development unit, catering not only to REGO-FIX’s internal team but also to its partners, customers, and engineering students. With over 320 employees worldwide, this facility operates with lean manufacturing principles optimizing production costs and efficiency across three shifts, six days a week. Further underscoring its advanced manufacturing capabilities, REGO-FIX utilises unique machines, specifically developed for its product range, operating with high levels of automation and the ability to function unmanned. This facility processes more than 800 tons of steel annually and exports over 90% of its products, which are factors that indicate how REGO-FIX’s manufacturing prowess extends far beyond Swiss borders.

Range of products on offer

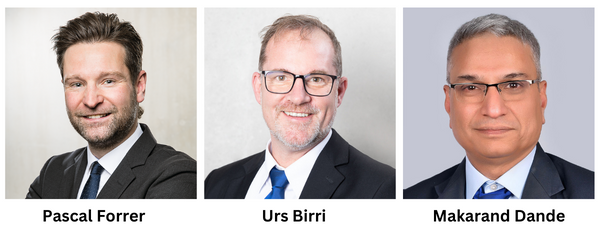

REGO-FIX offers a diverse range of products designed to meet the exacting demands of various industries. The company’s offerings include the ER Collet Chuck system, powRgrip, micRun, and Multi Line. The ER Collet Chuck system, a staple in the industry since its introduction in 1972, offers a wide variety of collet sizes to accommodate various applications. “As the inventor of the ER Collet Chuck system, we have put a lot of effort intoimproving the ER system over the years. Today, we can proudly say that we have the best quality ER collets and ER nuts on the market in regards to quality, reliability and manufacturing repeatability,” said Pascal Forrer, Global Sales and Marketing Director, REGO-FIX Group.

The powRgrip system is renowned for its exceptional runout and vibration-damping properties, making it well-suited for high-speed milling and drilling operations. On the other hand, the micRun system bridges the gap between the powRgrip and ER systems, providing a total system runout of ≤3 µm at 3xD, catering to applications demanding utmost precision. “The powRgrip® press-fit clamping system is an award-winning new technology that’s only available from REGO-FIX. It makes tool clamping easy, fast and reliable compared to other systems that use heat or deformation of the arbors to clamp a tool. For REGO-FIX, it is always the quality of the product, the reliability and the performance that sets it apart from others,” said Pascal.

Catering to a diverse customer base

The solutions engineered by REGO-FIX address common machining challenges such as tool pull-out, inadequate coolant supply, slip-offs leading to work injuries, and poor tool life. These products find applications across demanding sectors including automotive, aerospace, medical, watchmaking, mould and die, and machine tool industries.

In the automotive industry, REGO-FIX’s tool-holding systems effectively manage high process complexity and rapid technology cycles. In the aerospace industry, their systems excel in vibration damping and runout TIR, which is crucial for working with modern, high-tensile materials. For medical applications, the company’s products ensure absolute process reliability, critical for the successful certification of medical devices.

The watchmaking industry relies on REGO-FIX to maintain low production costs and prevent dimensional deviations, while the mould and die industry benefits from their high-quality equipment to avoid irregularities in moulds. Additionally, for machine tool manufacturers and OEMs, choosing REGO-FIX’s tool-holding systems is pivotal for achieving optimal machine performance and commercial viability.

R&D initiatives

REGO-FIX’s R&D endeavours are dedicated to addressing the intricate challenges encountered by industries relying on high precision and reliability. By engineering solutions that enhance productivity and align with customer requirements, REGO-FIX ensures that its tool-holding systems transcend being mere products, becoming essential components within a broader manufacturing ecosystem.

Highlighting the company’s R&D activities, Urs Birri, Area Sales Manager Asia, REGO-FIX Group, said, “REGO-FIX has always shown the will to improve things. This started when the company’s Founder Mr. Fritz Weber invented the ER system. The existing system (E-Collet) was difficult to use and had some disadvantages. He chose to improve it to better productionat REGO-FIX and realized that it had the potential to change the whole tool-holding industry at that time. Similarly, we believe that heating/cooling metal repeatedly cannot be the solution, especially considering the waste of high energy that occurs during this process. We believe the powRgrip® system is the answer.”

While REGO-FIX invests a significant part of its revenue towards R&D activities every year, the company also allocates a substantial annual budget towards upgrading its production machinery to remain at the forefront of technological advancements. “Additionally, we have internally developed certain machines to retain our know-how and experience within the company. Consistent investments are also made towards enhancing the infrastructure of our facilities, ensuring tight temperature control for both production and quality assurance processes to uphold the highest standards of quality and precision. All our products are manufactured at our headquarters in Switzerland,” emphasized Pascal.

The India opportunity

REGO-FIX is strategically expanding into the burgeoning Indian market. Acknowledging the rapid expansion in sectors such as EMS, aerospace, and medical, REGO-FIX aims to cater to the Indian clientele more closely. In 2023, the company inaugurated its subsidiary in Pune – India’s manufacturing epicentre – to leverage the immense potential of the local market.

“During the initial phase, REGO-FIX India will focus on understanding the customers’ needs and refining our services. The company is actively seeking feedback to navigate the learning curve. This critical period of the next twelve to eighteen months is dedicated to enhancing customer service and establishing efficient processes,” said Pascal.

Despite starting with a modest team, REGO-FIX India is poised for growth, with plans to expand its on-ground presence. The company’s commitment to the Indian market is evident in its investment in infrastructure and location. This venture is more than a business expansion; it’s a commitment to fostering long-term relationships with Indian customers and contributing to the country’s manufacturing prowess.

Emphasizing the significance of the newly launched subsidiary, Makarand Dande, Managing Director of REGO-FIX India Pvt. Ltd., said: “With our substantial office space and warehouse, our commitment to the Indian market is evident. This strategic move brings us closer to our customers, enabling efficient product delivery. As we continue to expand our team and distributor network, we aim to strengthen our presence in every corner of India.”

“We recently participated in the Die & Mold India International Exhibition in Mumbai and had the opportunity to engage with numerous customers and industry professionals. It became evident to us that the Indian market is primed for high-end solutions, with companies actively seeking to elevate the quality of their offerings. This realization bolsters our confidence in our solutions and underscores our anticipation for growth in the Indian market,” added Dande.

Looking ahead

As REGO-FIX sets its sights on the future, the company remains steadfast in its dedication to maintaining its legacy of precision and innovation. With plans to continue investing in cutting-edge technologies, REGO-FIX is committed to meeting the evolving needs of the industry.

Simultaneously, REGO-FIX is gearing up to expand its capacity, with the development of a new facility on the horizon, poised to bolster its manufacturing capabilities. This expansion underscores the company’s growth trajectory and its preparedness to meet the growing demand for its high-quality products.

In the Indian market, REGO-FIX maintains unwavering confidence in the country’s potential. Recognizing the significant opportunities presented by India’s dynamic growth, the company is eager to contribute to and benefit from the nation’s progress. REGO-FIX’s ongoing investments in India signify a long-term commitment to being an integral part of the Indian manufacturing landscape, fostering innovation and excellence in a market ripe with potential.

“REGO-FIX strives to achieve constant and healthy growth and continues to produce the finest and most reliable tool-holding systems for our customers. It is their satisfaction with our products, our services and our innovations that give us the opportunity to work out our best,” concluded Pascal.

Image Courtesy: REGO-FIX Group

COMMENTS