This year, global engineering technologies business, Renishaw, is celebrating its 50th anniversary. The company, which was founded on 4 April 1973, will mark this significant milestone with a year of global activities including open house events at its largest sites, family days for employees and a ‘50 at 50′ charity initiative which will see £150,000 donated to 50 not-for-profit organisations in the 36 countries where it has offices.

The Company was formed to commercialise the invention of a touch-trigger probe by now Executive Chairman, Sir David McMurtry, that solved a dimensional measurement problem faced by Rolls-Royce when manufacturing the Olympus engines that powered the supersonic Concorde aircraft. The probe also solved similar challenges being faced by many precision manufacturers around the world, ultimately allowing measurement on co-ordinate measuring machines (CMMs) to be automated for the first time.

Rolls-Royce took out a patent on McMurtry’s original design, which was filed on 21 September 1972, with him acknowledged as the inventor. He discussed the touch-trigger probe with a colleague, John Deer, now Renishaw’s Non-executive Deputy Chairman, who also saw the wider commercial opportunities for the invention and Rolls-Royce agreed to license the patent to them but would only do so if they had a limited liability company. For expediency, they therefore purchased an ‘off-the-shelf’ company and on 4 April 1973, the first Renishaw company, Renishaw Electrical Ltd., was registered.

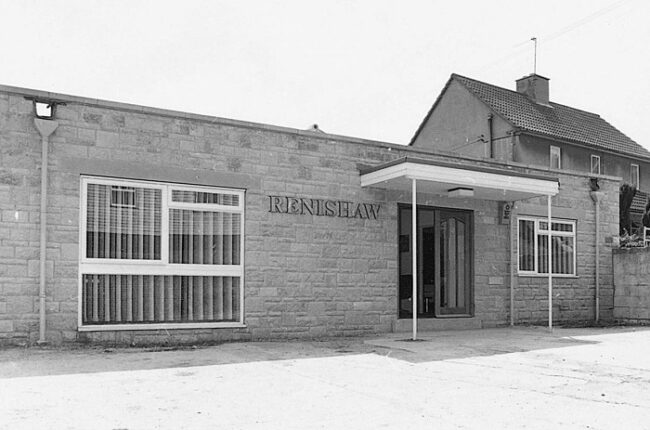

Renishaw New Mills Offices

McMurtry and Deer quickly saw the potential for the use of probes on computer numerical control (CNC) machine tools and in 1977 Renishaw launched its first commercial probe for machine tools. Although today, a significant amount of Renishaw’s business is still derived from contact and non-contact laser measurement systems for CMMs and machine tools, the Company now supplies a wide range of metrology systems for calibration, position feedback and gauging, plus associated accessories including styli and fixturing. It has also applied its core expertise in measurement, manufacturing and process control to develop systems for non-destructive testing using Raman spectroscopy, robots and drug delivery systems for brain surgery, and is also a technology leader in the field of metal additive manufacturing (3D printing).

Over the past 50 years, Renishaw’s products have revolutionised key aspects of component manufacturing and scientific research, contributing to the ability to make the high performing, precision products that we use in our daily lives. From the manufacture of aircraft, cars, smartphones, electric vehicle batteries and solar panels, to brain surgery and dentistry, there is barely an industry that does not in some way benefit from the Company’s ongoing innovations.

Sir David McMurtry and John Deer

Today the Company is listed on the London Stock Exchange’s FTSE 250 index, with a current valuation around £3 billion. It employs 5,200 employees in 36 countries, including 3,400 staff at its sites in the UK, primarily in Gloucestershire and South Wales.

Will Lee, Renishaw’s Chief Executive says, “This is a year to reflect on the tremendous achievements of our co-founders and employees past and present, who have done so much to advance precision manufacturing globally, and to look forward with confidence to future decades of innovation and growth.”

He adds, “The formula that has ensured Renishaw’s success over the past 50 years remains at the heart of our approach to business – investing heavily in research and development to ensure a continuing stream of world-leading products; a commitment to high-quality in-house manufacturing that ensures we can meet the exacting requirements of our global customers; and a focus on excellent local customer service and support through our wholly owned subsidiary operations.”

Lee concludes, “On behalf of Renishaw, I would also like to thank our customers and suppliers, many of whom we have had close relationships with for most of our history and with whom we have shared mutual success, and our other stakeholders, including our local communities who have been highly supportive of our growth and have also shared in our success.”

COMMENTS