SECO Tools has introduced the 335.18 Disc Milling Cutter, engineered to deliver reliable, efficient, and customizable slotting performance. Designed to tackle real-world challenges in slot, groove, and full side-and-face milling, the cutter ensures smooth operations and consistent results. Suitable for a wide range of applications—including automotive, aerospace, and general engineering—the 335.18 promises improved performance and reduced operational issues for manufacturers.

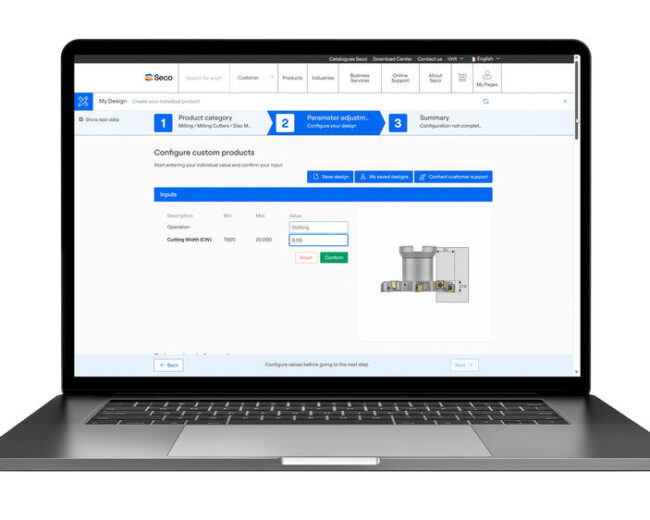

Design your own indexable slotting cutter

No two slotting operations are the same and that’s exactly why the 335.18 disc milling cutter stands out above the rest – already available in over 70 standard cutter variants – it has now been added to the intuitive MyDesign application where you can quickly configure and quote a cutter body that’s tailored to your exact needs—no waiting, no guesswork.

It’s the ultimate slotting tool for any machine, any material, and any industry.

Slotting operations often vary in width, depth, and corner radius, making it difficult to find a single tool that meets every requirement. SECO Tools addresses this challenge with its 335.18 system, which offers one of the broadest ranges available on the market. The system includes a wide selection of LNKT inserts with different corner radii, integrated wiper flats for superior surface finishes, and a comprehensive portfolio of grades and geometries. For unique needs, the MyDesign feature allows users to create a customized cutter body in just minutes, ensuring a perfect fit for every application.

Safe and stable Disc Milling operations

If you’ve ever dealt with unstable setups or long overhangs, you know how frustrating vibrations can be. The 335.18 cutter is designed to cut through that problem—literally.

Its smooth-cutting design keeps things stable and safe, even in tough conditions. It’s so reliable, it’s the only tool in its class that’s proven to work on robotic arms, setting a new standard in slotting tool performance.

Weak setups and long overhangs in machining often result in vibrations, poor surface finishes, and even tool failure. The SECO 335.18 cutter effectively addresses these issues by minimizing cutting forces and maintaining stability throughout the operation. The result is improved machining performance, reduced downtime, and consistently smooth results, even in the most demanding environments.

Cost-efficient machining without cutting corners

Why choose between performance and cost when you can have both? The 335.18 cutter uses double-sided inserts with four cutting edges, combined with peak-performance grades and a long-lasting cutter body. This results in longer tool life and fewer replacements and saves you money without cutting corners.

Tooling costs can escalate quickly, especially when tools wear out prematurely or fail during operation, causing production stoppages and higher expenses. This challenge is particularly critical in high-volume manufacturing environments where reliability is essential. The SECO 335.18 cutter provides a robust solution, crafted from high-quality Swedish steel to ensure durability and dependable performance. Its extended lifespan not only reduces replacement frequency but also supports sustainable manufacturing, delivering greater value for every investment.

COMMENTS