Perfect and reliable coating of brake discs

In many cases, today’s brake discs are being phased out because they do not meet the regulations of the EURO 7 standard. The reason for this is an innovation: for the first time, the standard regulates not only emissions from combustion engines, but also abrasion from brakes and tires. The car is therefore considered as a whole, and particulate emissions from the braking system must be greatly reduced.

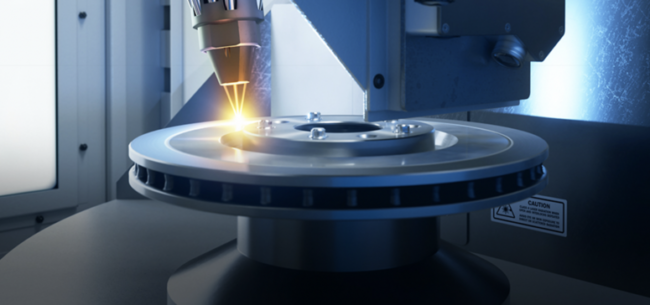

In this context, laser metal deposition is becoming the decisive technology in this field of application. With its help, the conventional brake disk is simply given a new layer that offers protection against corrosion, wear and fine dust – and does so quickly, efficiently and reliably.

The new production solution from EMAG and HPL Technologies is economical, suitable for large-scale production, process-reliable – and variable, as a variety of material combinations can be used in the coating process.

Find out in the detailed white paper how our process combines both laser metal deposition and grinding of the brake disc – making it unique on the market.

Whitepaper Link – https://www.emag.com/company/news-media/media-center/whitepaper-laser-metal-deposition/

COMMENTS