Quality control using artificial intelligence reduces waste and costs // VisionLine Inspect solution can be used, for example, in the production of batteries for electric cars or in car body construction // Users do not need any programming knowledge.

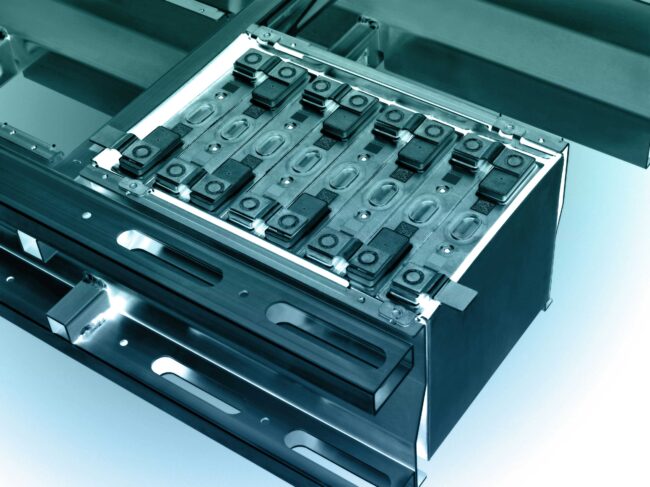

TRUMPF is using artificial intelligence (AI) to increase productivity in automotive manufacturing. The high-tech company has developed an AI solution that checks the quality of components, such as batteries for electric cars, immediately after laser welding, identifies possible defects and enables repairs in the laser welding station. “This enables users to reduce their manufacturing costs because the AI solution can replace other time-consuming quality inspections,” says Martin Stambke, the TRUMPF product manager responsible for AI quality inspection. The first customers from the automotive industry are already using the solution in series production and the high-tech company is now presenting it at its in-house exhibition INTECH.

AI solution suitable for many applications

The solution takes a picture of the weld seam and AI analyses whether it meets the specifications defined by the user for the manufacturing process. The sensor technology generates traceable measurements for the user, enabling transparent quality control without black-box decisions. For example, if the weld is too narrow or too wide, the AI notifies the user while the component is still in the laser cell. The operator can quickly decide if a repair is necessary, thus ensuring the quality of the weld. This increases first-pass yield, the proportion of components that meet quality standards on the first pass. “This is particularly important for manufacturers of batteries for electric cars, for example, who will have fewer rejects and thus reduce costs,” says Stambke. The AI solution is suitable for many other applications, such as welding body parts, hairpins for electric motors or contacts for electronic components.

No programming knowledge required

“Customers get an easy-to-use AI tool that integrates seamlessly with the TRUMPF system of lasers, sensors and optics,” says Stambke. Users can use the TRUMPF AI without any programming knowledge. All you have to do is train the artificial intelligence before using it. To do this, the user marks correct and incorrect welds in the corresponding image material. For the training process, TRUMPF offers EasyModel AI, a software program that is as easy and intuitive to use as a smartphone app. Only a few training images are required.

COMMENTS