When it comes to digitalization, sometimes you can’t see the really important solutions because of all the hyped-up topics. Experts agree on what these are. Find out which technologies you should not ignore and how companies in the industry are already using them.

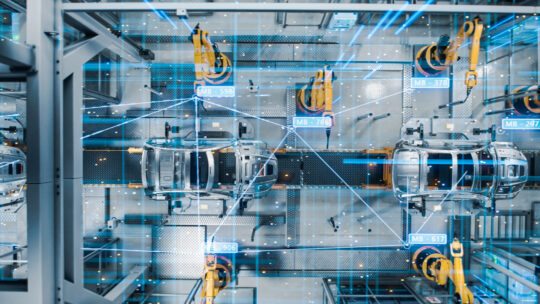

The digital transformation has reached the machine tool industry. It is in the process of fundamentally changing the way we produce. Numerous innovative technologies and concepts are the driving forces behind this change. They offer companies diverse potential for increasing efficiency, improving quality and reducing costs.

The focus here is on networked production, the collection and analysis of large amounts of data, as well as the use of simulations and digital twins to optimize processes and products. In addition, ERP systems, the Internet of Things (IoT) and artificial intelligence and machine learning also play a key role.

According to various experts, these are all essential building blocks for the factory of the future. The integration of these technologies not only enables transparent monitoring and control of production processes, but also opens up new possibilities for predictive maintenance and efficient use of resources.

Tools for data collection and processing are a must

The most important thing for modern production is the data and its processing. This is the basis for all other digitization solutions and is therefore particularly relevant for beginners. On the one hand, new digital tools are needed to handle data efficiently, but even established systems often provide more information than expected, reports Prof. Michael Zäh, President of the German Academic Association for Production Engineering (WGP) and Head of the Institute for Machine Tools and Industrial Management (IWB) at the Technical University of Munich.

“The ERP system is essential, but today it has almost become a matter of course in manufacturing companies,” he says. “Many conclusions can be drawn from its database, which I am convinced is not yet fully understood in the industry.” The repetitive generation of simple basic data for business processes is no longer necessary, and there is also potential for rationalization in the design of processes. This makes order processing less error-prone.

Sascha Fischer agrees that the initial focus should be on collecting and analyzing data. He is Vice President Machine Tool Systems at Siemens Digital Industries in Nuremberg. “It is important to install suitable sensors and measuring systems in order to collect relevant data that can then be used to optimize processes,” he explains. “The integration of an advanced CNC solution such as Sinumerik can be considered the key element for getting started with digital technologies.” The digital twin then enables a risk-free introduction to virtual commissioning and promotes a deeper understanding of the production process. More on this later.

Examples from the machine tool industry show how to make good use of data: Grob relies heavily on the machine data acquisition of its Grob-Net4Industry digitalization solution in its own production. “With our specially developed machine data acquisition system, which also enables the acquisition of process and control data from third-party machines, we have digitalized our entire production process,” reports Benedikt Gundling, Product Manager Digital Products at Grob-Werke GmbH in Mindelheim, Germany. “For sensitive production data, we use products that run locally on our own servers.” This includes a tool for the complete digitalization of the tool cycle and a dedicated MES system that uses SAP as a database.

In addition, the in-house digitization solution offers even more options for handling the data. Grob4Analyze, for example, enables the historical analysis of machine data to identify unproductive phases and the reasons behind them. This is intended to support the continuous improvement process (CIP) with visually prepared data.

“In addition to our own developments, we also rely on established software from other manufacturers, such as CAD/CAM systems,” adds Gundling. He goes on to explain that “manufacturer-independent machine data acquisition in conjunction with our detailed machine analysis, including real NC program runtimes and process data visualizations, is usually the starting point for a discussion about the possibilities for uncovering optimization potential in our customers’ production processes.”

Lathe manufacturer Index in Esslingen also relies on data acquisition in its own production, as Eberhard Beck, Head of Control Technology, explains. Both machine and operating data are recorded and evaluated centrally in a dedicated cloud application (iXcloud). Examples include machine downtime messages, error code transmissions and media monitoring (hydraulic oil, lubricating oil, cooling lubricant) with regard to fill level, average consumption and refill prediction in the cloud.

Simulation with digital twins improves production processes

The collected data can be used for simulation purposes. But why is this important? The experts agree that simulations in various forms are indispensable for the digitalization of the machine tool industry and its customers. This is because simulation has an important role to play, for example, in quality assurance thanks to the detection of errors in advance and in increasing efficiency by optimizing processes.

“Modern production planning uses digital tools in the field of geometry and kinematics, such as simulation systems for detecting programming errors in automated systems,” reports Zäh. “Discrete event simulation systems can also optimize the material flow.”

In this context, Fischer from Siemens points out digital twins that simulate physical processes in a virtual environment and can improve both product development and production planning. His reasoning: “Digital twins improve production processes in metalworking by optimizing product development, enabling more efficient maintenance and supporting production optimization by simulating different manufacturing scenarios.”

His view is based on the fact that digital twins make it possible to virtually simulate and test the entire production process. In particular, the simulation is used to verify the work processes and for collision monitoring. This is possible with Sinumerik One and Sinumerik 828D, for example.

Digital twins can also be used for service and commissioning training. Machine operators can thus be trained in secure, completely virtual environments. This in turn increases the quality and efficiency of real production processes, says Fischer.

Machine tool manufacturers also rely on this type of simulation, and in various places: “We use digital twins for the most part in development,” reports Gundling from Grob. “Here, we use physically correct digital twins of our machines for holistic simulations.”

For Beck from Index, digital twins are “the central basis for completely closing the gap between program creation – CAM output, manual – and the start of production.” Index uses Siemens technology to obtain a digital twin as a fully comprehensive machine simulation based on the CNC kernel, the original CNC control and the CAD machine model of the machine design. A complete collision check is also carried out.

In addition to digital twins, Index also relies on a CAM workpiece simulation based on a general CNC controller to check the G-code in terms of the workpiece contour.

Networked production: IoT and interface technologies are crucial for success

If you want to fully benefit from digitally optimized production processes, you need simple networking of machines and tools. This requires interfaces, but also standards for data exchange such as OPC-UA.

Another technology that plays a key role in this is the Internet of Things (IoT), emphasizes the digitalization expert from Siemens. He therefore considers it to be one of the most important technologies for meaningful digitalization in the machine tool industry. “The IoT enables the networking of machines and systems, which allows continuous data collection and analysis,” explains Fischer. “Artificial intelligence and machine learning make it possible to identify patterns from large amounts of data and further optimize processes.”

When it comes to particularly important digitalization technologies, “extended connectivity through modern interface technologies should also be mentioned, which supports machine connectivity and strengthens areas such as preventive maintenance and remote monitoring,” says Fischer.

Connectivity is also at the top of Grob’s digitalization list. This is demonstrated by our own Industry 4.0 solution Grob-Net4Industry. The manufacturer not only uses these in its own production, as previously mentioned, but has already digitized over 1,805 machines in total.

“Our digital solutions create transparency and cost efficiency for 76 customers worldwide,” reports Product Manager Gundling. “Our solutions are the result of our own production requirements and are constantly being developed further in collaboration with our customers.” With Grob4Interface, the Mindelheim-based company offers manufacturer- and age-independent connectivity for the entire machine fleet. Grob4Connect enables the integration of production in the SAP system.

At Grob itself, this networking not only brings advantages in terms of productivity, but also makes everyday life more pleasant for employees: “In addition to detailed evaluations of the machine utilization history for store floor management, we can also design attractive work time models that enable remote monitoring of the machines from home,” explains Gundling.

The manufacturer Index in Esslingen also relies on various interfaces in its machine tools. Beck speaks of (bidirectional) DNC networking of the machines for CNC program transfer and distribution. Various applications are also used. These include Ethernet interfaces for network communication and data exchange between the machine and the company network as well as Profibus/Profinet interfaces for communication and integration of automation components (machine-to-machine communication) such as bar feeders and loading/unloading systems or robots.

Interfaces therefore play a decisive role in enabling data exchange, integrating systems and thus realizing efficiency increases, improved monitoring and new functionalities such as remote maintenance and predictive maintenance.

Which technologies will shape the future of digitalization?

“The combination of digital twins, advanced data analysis and seamless integration into digital networks points the way forward for digital transformation in the manufacturing industry,” summarizes Fischer from Siemens. But other technologies will increasingly be added.

Siemens sees great potential in technologies such as 5G, which enables extremely fast and reliable data communication in real time. According to Fischer, edge computing for fast processing of data directly at the source will also gain in importance. And, of course, artificial intelligence as a key technology for increasing efficiency and realizing smart factories should not be missing.

“The technologies integrated into Sinumerik, such as digital twins, advanced data analysis and seamless integration into digital networks, signal the direction in which Siemens is looking ahead,” explains Fischer. “For example, Siemens offers a concrete application of AI in the manufacturing process of machine tools with the ACM (Adaptive Control and Monitoring) tool.” ACM uses machine learning algorithms to monitor production processes in real time, detect anomalies and make automatic adjustments. According to Siemens, this reduces downtimes, improves product quality and increases overall system effectiveness.

Zäh from WGP has a clear answer as to what will be the most important digital technology for production in the future: “Machine learning, also commonly referred to as artificial intelligence. I am convinced that these approaches offer concrete and often quantifiable potential for rationalization and improvement for most companies.” AI is far more than just a buzzword. However, risk awareness is also required when working with other companies in networked environments.

COMMENTS