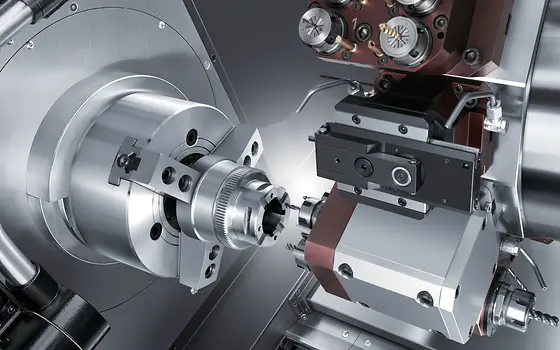

DMG MORI has unveiled the new NLX 2500|1250, a fully modernized edition of its best-selling universal turning machine. Designed for demanding sectors such as medical, automotive, and energy, the second-generation model delivers enhanced spindle options and improved performance for both high-speed heavy-duty and precision machining.

The NLX 2500|1250 accommodates workpieces up to 1,258 mm in length and 366 mm in diameter. Equipped with left and right spindles, a turret with driven tools, an extended Y-axis travel of +/- 60 mm, and a tailstock, the machine enables highly flexible 6-sided machining of complex components.

Spindle Power Redefined

Both the left and right turnMASTER spindles have been significantly improved in terms of performance. Spindles measuring 10″ and 12″ are available on the left. The former achieves 5,000 rpm, a torque of 843 Nm and an output of 26 kW. The larger spindle reaches 3,000 rpm, 1,273 Nm, and 36 kW. Three spindles measuring 6″, 8″, and 10″ are now available for the right side. The smallest version operates at 7,000 rpm and 95 Nm. The newly added largest spindle reaches 5,000 rpm and a high torque of 577 Nm. With an average service life of 20 years in mind, DMG MORI has redesigned the compact MASTER spindles and revised both the ball and roller bearings. In addition, the bar passage has been increased to ø 105 mm on both sides, while the spindles run with a roundness of 0.5 µm.

Turret Options Expanded

The versatility of the spindle range continues with the selection of turrets. As standard, the NLX 2500|1250 2. Generation is equipped with a BMT60 turretMASTER, which offers space for twelve driven tools. There is also a BMT60 with ten stations, a BMT40 with 20 stations and a VDI40 turretMASTER with twelve stations. The driven tools operate at speeds of up to 12,000 rpm or – in the case of the BMT60 with ten stations – a torque of 100 Nm, which gives the NLX 2500|1250 2. Generation the milling properties of a machining center. DMG MORI offers a 36-month warranty on all turretMASTERs.

Precision Engineering Enhanced

Since the NLX series has always stood for maximum precision, DMG MORI has also made additional optimizations in this area. The stability of the cast bed and the rigidity of the moving components have been increased, and double-bearing ball screw drives have been implemented. The intelligent temperature management system takes all heat sources into account and reliably counteracts them, ensuring high long-term accuracy even in automated production. In addition, direct encoders on all axes ensure high positioning accuracy, which is increased by a factor of 5 with the help of Magnescale’s MAP correction. This means that the NLX 2500|1250 2. Generation is also suitable for precision machining, allowing even more scope for process integration.

The app-based CELOS X manufacturing platform on MAPPS with FANUC or on a SINUMERIK ONE from Siemens supports users with intuitive operation and paves the way to digital manufacturing. In the case of demanding applications, exclusive DMG MORI technology cycles simplify programming, for example gearSKIVING in the case of gear teeth.

Perfectly equipped for automated and sustainable production

Thanks to a plug & play interface, NLX 2500|1250 2. Generation is easy to automate. The possibilities range from bar loaders to robot-based solutions such as Robo2Go, MATRIS light, and the MATRIS system. Optimized chip fall, sophisticated coolant and chip management using zero-sludgeCOOLANT, and a self-cleaning chip conveyor support reliable, autonomous production. Both zero-sludgeCOOLANT and the zeroFOG emulsion mist separator also ensure more environmentally friendly production. With these and other measures—such as 400 V operation—GREENMODE significantly reduces energy and resource consumption.

COMMENTS