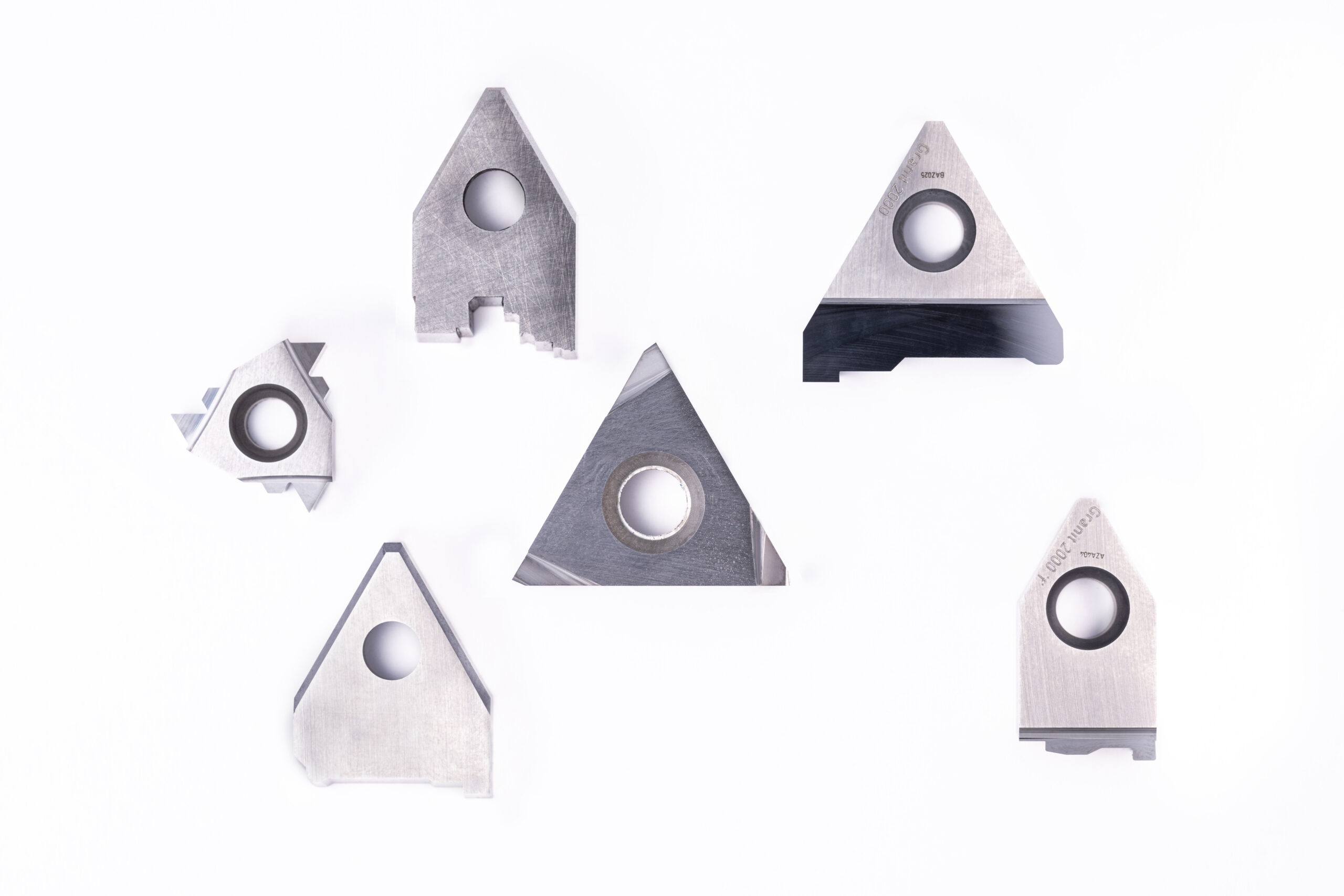

ANCA has recently announced the launch of InsertsPRO, its new Special Inserts Grinding Package. The powerful, flexible, and universal software solution is designed to support manufacturers in the rapidly expanding insert grinding market, a sector valued in the billions worldwide.

With indexable inserts representing a significant share of global cutting tool consumption, InsertsPRO enables manufacturers to achieve higher efficiency, precision, and adaptability in insert production, further strengthening ANCA’s leadership in CNC grinding innovation.

InsertsPRO supports ISO-standard inserts sourced from global catalogues – suitable for any milling or turning machine—as well as customer-specific special inserts developed for optimized applications, all on a seamless, automated platform. Designed to deliver flexibility, speed, and premium quality output, InsertsPRO is the smart choice for tool makers looking to reduce costs, optimise cycle times, and future-proof their production. Manufacturers can leverage ANCA’s MX7 platform to access the full functionality of InsertsPRO, and further process optimization (e.g., wheel capacity, cost reduction per part) can be achieved using other ANCA platforms.

“InsertsPRO is ANCA’s answer to the market’s demand for a universal, high-performance insert grinding solution,” said Eduard Kleinschmidt, ANCA Inserts Product Manager. “With unmatched flexibility and automation, it empowers our customers to produce inserts efficiently, accurately, and profitably – all within one intuitive software environment. Grinding inserts without limits is absolutely what we can now deliver.”

High-Quality Tools and Profitability in One Package

InsertsPRO delivers:

- Faster setup and changeovers through automation and smart workflows

- Reduced operator intervention and downtime for greater productivity

- Lower production costs with optimised grinding strategies

- Advanced simulation for first time-right production and fewer scrap parts

- Seamless integration into existing ANCA ToolRoom RN35 workflows

Whether for threading tools in automotive, profile inserts for aerospace, or custom geometries in medical machining, InsertsPRO enables manufacturers to unlock unmatched flexibility, automation, and profitability.

Why InsertsPRO is Making a Difference

Indexable inserts form a critical part of modern machining across industries such as automotive, aerospace, medical devices, and advanced materials. Manufacturers are seeking ways to reduce setup times, manage frequent changeovers, and scale automation for consistent quality. Across applications demand is rising for specialised profile inserts that can deliver tighter tolerances, higher productivity, and reduced material costs.

“InsertsPRO isn’t just software—it’s a future-ready platform that transforms insert grinding into a smart, automated, Industry 4.0 process,” added Eduard Kleinschmidt. “We’re proud to bring ANCA’s innovation, precision, and reliability into the insert segment, giving our customers a competitive edge in a fast-growing market.”

Flexible Grinding with Practical Automation and Productivity Features

InsertsPRO is fully integrated into ANCA’s ToolRoom RN35 software, and existing ToolRoom users can upgrade to enjoy a comprehensive suite of features – bringing modern insert grinding capabilities to their current machines:

- Advanced Simulation Tools – High-resolution 3D visuals, grinding path simulation, and integrated measurement

- Flexible Profile & Rake Face Design – Profile editor or DXF overlay with precise lead-in/out control

- Multiple Cutting-Edge Support – Uniform edge geometry with automated X-axis rotation

- Flexibility in Clamping Orientation – Fast changeovers with advanced transformation

- Optimised Relief & Rake Grinding – Wide range of styles, wheel types, and compensation options

- CIM3D Integration – Process validation, collision detection, and optimisation for first time-right production

Future Ready Insert Grinding

With Industry 4.0 transforming manufacturing, InsertsPRO positions ANCA as a key partner for insert production, offering a software-driven solution without limits. By combining automation, flexibility, and precision, InsertsPRO helps cutting tool manufacturers scale efficiently, adapt to evolving applications, and achieve consistent quality with a wide range of insert types.

COMMENTS